OR Laser gained their fame last year by announcing a powerful 3D metal printer. Now it just got better.

As we saw last year, the company uses a direct deposition technique as opposed to the more frequently encountered powder-bed / laser approach used by most of their competitors.

In the OR Laser system, a fine stream of tiny metal particles is aimed at a fusion point, where a powerful 250W fibre laser immediately melts the particles and fuses them to the growing print structure.

This approach is further differentiated by their unique circular motion path. The deposition system revolves around the build volume, which, according to OR Laser, can result in build times around 30% faster.

Designed for office use, the relatively small-volume 3D metal printer is suitable for 3D printing small prototypes or even jewelry. The system is also capable of 3D printing in gold or other precious metals, but as you might imagine, the materials are pricey in those cases.

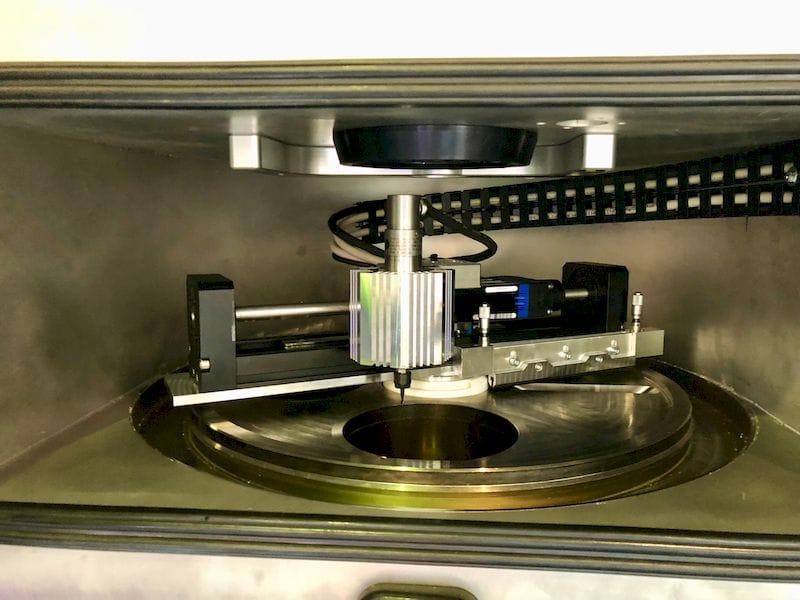

But this year they’ve added a new feature to what they’re calling the “hybrid” machine: a milling head.

In the hybrid’s print operations, printing ceases every 5-10 layers, whereupon the milling head is engaged. It slides around the external contour of the previously printed layers and trims off excess materials. In fact, it smooths the layers of the printed metal just as good as a CNC machine could do – because it IS literally a CNC machine inside the 3D printer.

The milling is performed every few layers to avoid complications with difficult geometries, but for most prints would result in parts that are nearly perfect and require very little, if any, post processing.

This is quite different from other 3D metal printers that issue “completed” parts that must be finished in complex, time consuming and expensive ways.

I suspect they are trying to fit better into the office environment with this approach, because it avoids a few steps, making life easier for the office users, who would otherwise have to send out the part for post-processing.

OR Laser explains the Hybrid machine is still in development, but is expected to be released in the second half of the 2018, with an estimated price in the €180K range (USD$210K).

Via OR Laser