Charles R. Goulding and Preeti Sulibhavi look at recent trends in the automotive industry.

A recent New York Times (NYT) article, published on August 31st, 2022, highlighted a new auto trend – an industrial concept referred to as “circular manufacturing” for recycling auto parts. The idea is to break the cycle of “take, make, use and toss” by manufacturing cars whose components can be reused to assemble new cars. There is no one place to start and each part of the cycle is equally important. In addition, this industry is not regulated and that means there is no one, central problem to start addressing.

Although a daunting challenge, the benefits appear to be outweighing the challenges. The concept is to reduce the amount of energy and material that go into producing a car by using recycled materials for parts and/or by using green energy, like wind and solar, in production.

Luxury cars are also riding in on this trend. BMW introduced its iVision concept car that is completely recyclable at the International Motor Show in Germany.

The Auto Industry & 3D Printing

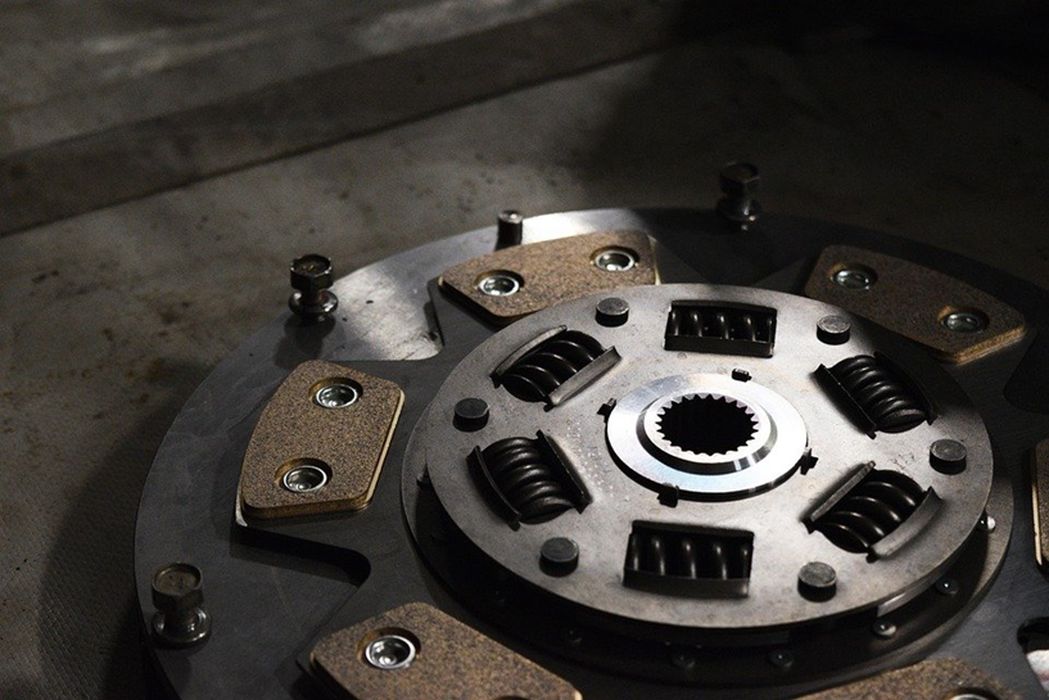

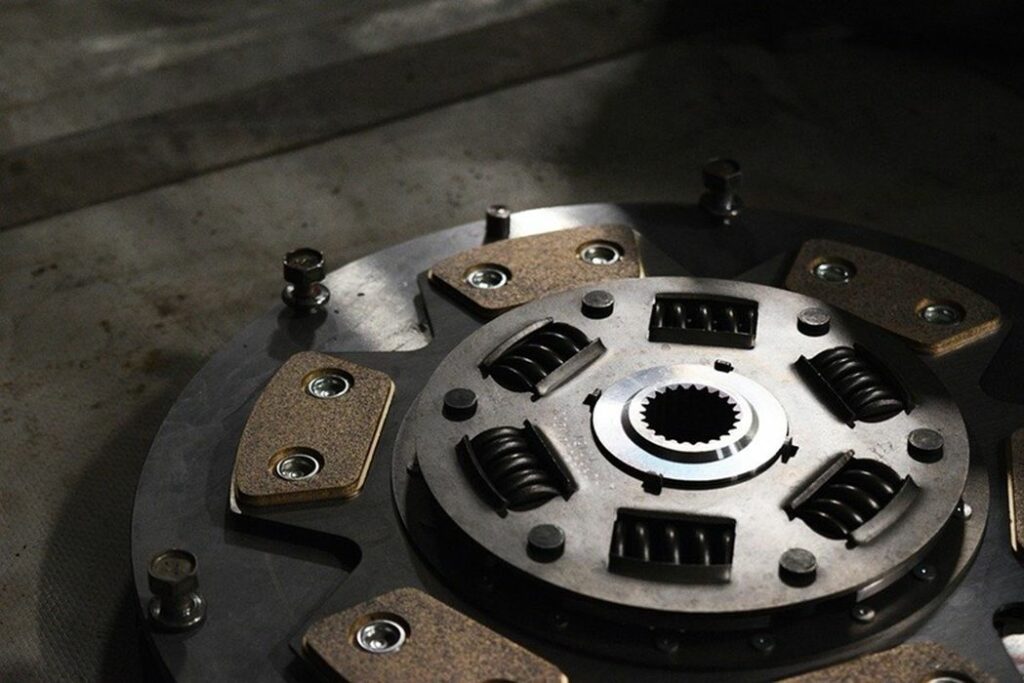

Circular manufacturing involves reducing the amount of energy involved in production. 3D printing fits into this concept in that it reduces the amount of material used in a car by about 40 percent while maintaining structural stability. American sedans are composed of approximately 20,000 components so there is a major opportunity here.

The NYT article also quoted Kevin Czinger of the company Divergent Technologies which produces the Czinger 21C, a 3D printed car. He discussed how 3D printing allows for atomizing the 3D printed parts into a powder that can be reused. This reduces the amount of energy used because materials are being extracted through mining.

This is not an entirely new concept. A team of students at the Eindhoven University of Technology in the Netherlands has been working to produce recyclable concept cars for several years now.

The fully electric, battery-powered Zero Emission Mobility (ZEM) vehicle not only captures carbon dioxide as it drives, but it is also is made using additive manufacturing to further limit carbon dioxide emissions and material waste from the production process. Components of the car, such as the monocoque and the body panels, are printed with circular plastics that can be shredded and reused.

In addition, with the global supply chain disruption for auto parts, 3D printing offers a viable alternative to traditional original equipment manufacturer (OEM) parts. Luxury cars are riding in on this trend as well. Aston Martin has used a Divergent 3D printed subframe for its DBR22 convertible introduced just this year. In these instances, the eco-friendly nature of the vehicle does not mean it is “wallet-friendly,” as the price is set at around US$2M.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Circular Reasoning

It is not a huge surprise that this recycled auto parts trend is occurring at this time. With 3D printing being used for auto parts for some time now, it could be considered the next step in advancing auto manufacturing technology.