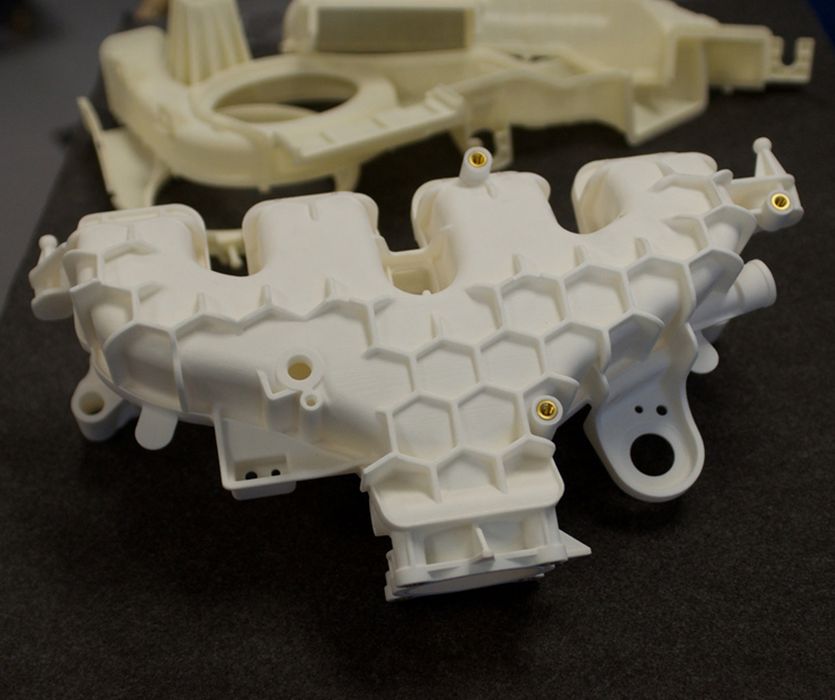

3D printed plastic spare parts for Mercedes-Benz trucks [Source: Plastic & Chemical Trading]

Charles R. Goulding and Preeti Sulibhavi envision a new application for 3D printing.

Service repair trucks are a common sight on roads and highways.

For many, service repair trucks are a navigational hindrance that often slows travel down. But we are not writing to air our road trip grievances.

A shortage of computer chips, used for various service truck components (i.e. airbags, engines, etc.), is causing an acute shortage of service repair trucks, similar to shortages in other industries. Construction contractors, home cleaners and other service-based companies that use this method of transport are struggling to find new work vehicles, creating a bottleneck for such businesses that are now experiencing increased demand for their services amid an economy eager to bounce back.

The shortage is impacting the aftermarket truck modification business as well. Everything from special lighting fixtures to customized shelving. With a normal service truck market, the first visit after purchase is to an aftermarket shop. This is a good time for aftermarket shops to invest in more 3D printing resources.

3D Printing, At Your Service

The aftermarket industry can be prepared for the eventual resumption of repair service vehicles and to refurbish existing trucks that are being pushed into service for longer amounts of time.

We have previously written about 3D printed truck parts on Fabbaloo. In fact, 3D printing affects all trucks, from fire rescue vehicles to metropolitan bus transportation, there are always components or truck parts that can be 3D printed, either for improvements or repairs. There are even aspects of truck stops that are not excluded from 3D printing applications.

The Research and Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software. As of 2016, eligible startup businesses can use the R&D Tax Credit against $250,000 per year in payroll taxes.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Lemons

When life hands you lemons, you make lemonade (as the old adage goes). With today’s acute service repair truck shortage, should an aftermarket business get a 3D printer and learn to print some replacement parts for the trucks that will inevitably come to your shop for service due to extended use?