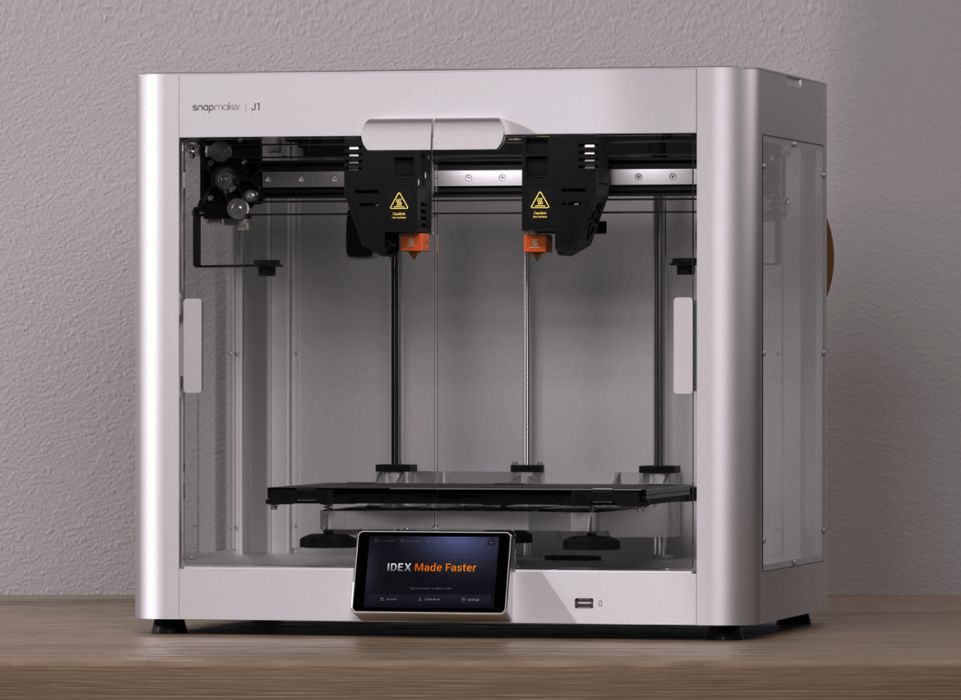

Snapmaker announced a new and advanced dual extrusion 3D printer, the Snapmaker J1.

The company has been around since 2016, and is best known for their “3 in 1” devices, which can perform not only 3D printing, but laser engraving and CNC milling, although at low power. Their all-metal device launched on Kickstarter in 2019 raised US$2.2M, while a followup 2.0 system in 2020 raised an amazing US$7.9M through the sale of thousands of machines.

Now the company is taking a bit of a different direction in announcing the J1, the company’s first IDEX machine.

A word about “IDEX”. This stands for “Independent Dual EXtrusion”. The concept is to have two separate extrusion toolheads that can move independent from each other. Some more primitive dual extrusion concepts have co-mounted toolheads that move synchronously, but IDEX provides much more flexibility.

Why shift to IDEX when the company has been making 3-in-1 devices? It turns out there is a bit of a story here. Snapmaker explains:

“The Snapmaker J1 is a project created by members of Snapmaker’s early founding team after leaving Snapmaker. At first, the J1 team found that auto-calibration was lacking in IDEX 3D printing and thereafter they pioneered the development of this feature. In November 2021, after nearly a year of R&D, the J1 team decided to return to Snapmaker and benefit from Snapmaker’s existing innovative technology and well-established operation system so that J1 can better fulfill the commitments to its supporters.”

It’s common for inventors to leave a company to pursue a different idea, but quite rare for them to come back to the original company. Well, that’s the case here, and it seems they have been successful in developing the new J1 IDEX concept.

IDEX provides several big advantages:

- Ability to 3D print two objects simultaneously, or two “mirrored” objects

- Ability to use multiple colors or materials in a single print job

- Ability to use soluble support, enabling easy printing of highly complex models

- Elimination of color mixing found with single nozzle dual solutions

- Precision material matching from the dual extruders

But that’s not all, as the Snapmaker J1 has several other interesting features.

One of them is that the device is constructed very robustly with one-piece die cast frame and base, aluminum alloys, which should make the machine extremely rigid. The motion system includes high-precision linear rails that provide near frictionless movement.

All of this enables the J1 to have a powerful motion system that can operate at quite high print speeds. Snapmaker said the J1 can reach print speeds of up to 350mm/s, which is a great deal faster than the typical 40-60mm of today’s inexpensive desktop 3D printers.

The J1 can use the fast motion system to rapidly 3D print objects with the IDEX extrusion system in copy mode, mirror mode, or something called “backup mode” that I have to learn more about.

The extrusion system’s hot ends are capable of hitting 300C, making them capable of 3D printing many engineering materials beyond the PLA, ABS and PETG on common equipment. In addition, Snapmaker said the extruder design is fully compatible with flexible TPU material, meaning you shouldn’t have to swap extruders to print flexible materials as is the case on some other machines.

While Snapmaker announced the J1 3D printer today, it cannot be ordered until November 8th at their online store. At that time they will accept pre-orders, with the machine to ship at a later date yet to be announced.

Pricing of the machine is also very interesting. The company’s MSRP for the J1 is US$1,399, which is a very good price for an IDEX 3D printer. However, during the pre-order period Snapmaker has reduced the price to only US$1,099. That’s an outstanding price for an IDEX 3D printer.

Via Snapmaker