Charles R. Goulding and Preeti Sulibhavi examine the notion of 3D printing soap.

Possibly one of the most basic items we own is soap. It is used almost without any thought given to it. That is until COVID-19 hit the world. It has since risen to great prominence and critical importance.

There are many forms that soap can take. They include bar, liquid, foam, crystal, you name it they’ve formulated it. There are also a plethora of scents, colors, shapes and sizes for soap and its varied forms. Soap can also be formulated for certain skin conditions as well (dry, extra dry, psoriasis, acne-prone, anti-bacterial, etc.).

People have also taken soap-making as a hobby. Whether it is a soap-making kit, or ingredients from one’s kitchen, soap-making can be time-consuming and labor-intensive. Particularly if making artisan, handcrafted soap bars. Using these artisan soap bars to prevent the spread of the novel coronavirus is another added benefit.

There is one aspect of soap that is being experimented with: 3D printed soap.

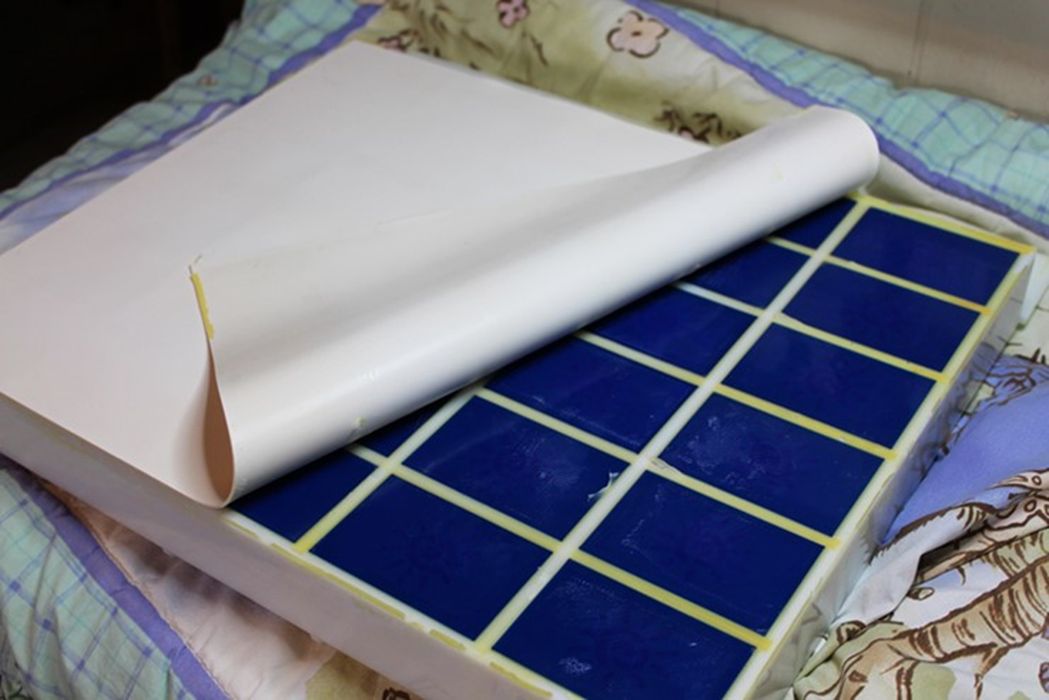

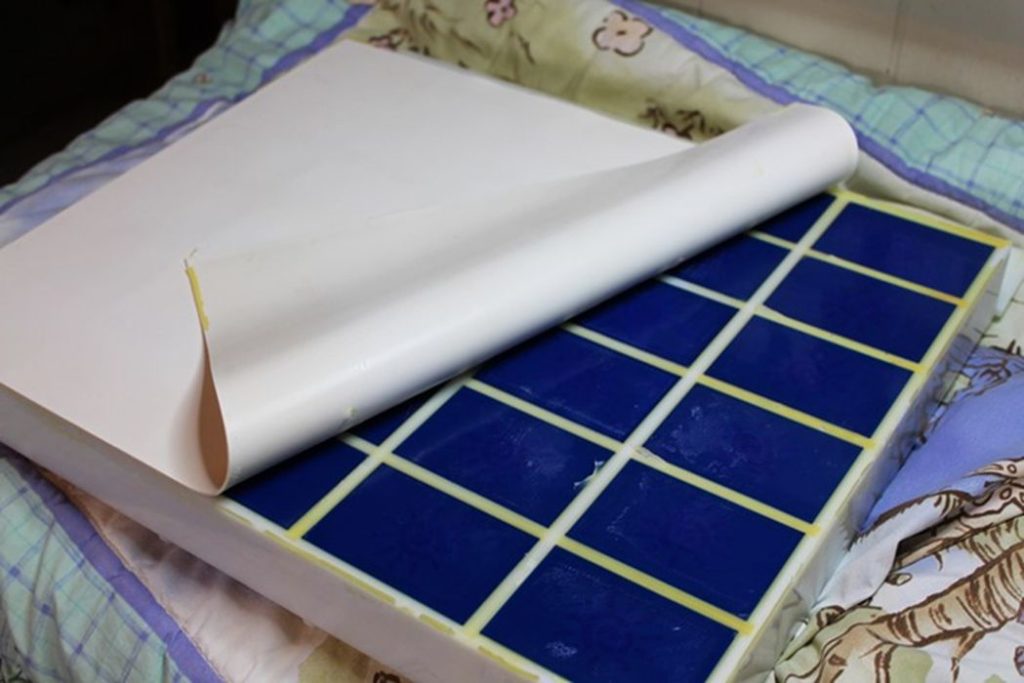

There are a few ways of 3D printing soap molds. There is the recyclable method where a Soap01 3D Printer, developed several years ago, takes the thin piece of soap bar often left behind in the shower (or simply breaks in half rendering itself useless) and repurposes the soap scraps into a perfumed 3D model for your next bath. Or the other 3D printing opportunity is to 3D print semi-flexible soap mats that soap batches can be poured into. The key is to use a silicone-like material for the line to prevent sticking and clinging when casting. While there are distinctions between being non-toxic and food-grade acceptable, soap can be 3D printed and there are ways to achieve great results.

Last year, the soap ring came into being and was geared to help reduce the spread of COVID-19. When in public spaces and there is no soap, why not have your own supply in the form of a ring? Soap you can take with you and use if there is no washroom available. Copper 3D printing technology helped in developing this idea into a product. Instead of a jewel in the center, there’s a piece of artisan soap.

Procter & Gamble and 3D Printing

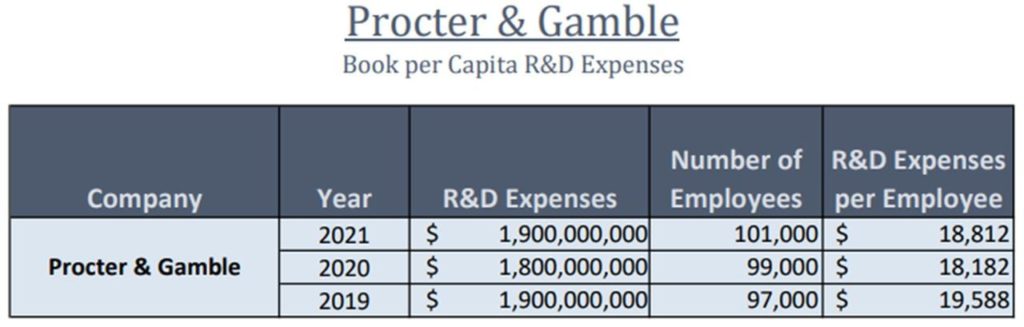

From Ivory to Olay, Procter & Gamble (P&G) manufacturers some of our favorite commercial soaps. P&G has previously teamed up with Aether, an AI 3D bioprinting company, to develop state-of-the-art 3D printing and AI technologies to improve P&G’s product research workflow. The families of P&G are also heavily invested in 3D printing as well as further research and development.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Soap is used for hygienic purposes, but it is also a form of relaxation and rejuvenation. Recently, due to the pandemic, soap has become of utmost importance to protect against the spread of germs. There is room for 3D printing to enter this market, particularly at this time.