Spare Parts 3D has developed a unique system for generating 3D models from technical drawings.

The French company’s purpose is to provide systems for implementing the digital inventory concept. The idea is to replace physical warehouses with digital databases, and then 3D print the spare parts when required. This concept eliminates a significant amount of expense to fill and maintain spare parts warehouses.

A big problem in pursuing that goal is that many companies actually don’t have digital 3D models of their parts. A company might have tens of thousands of parts in their catalog, with many being designed before the widespread use of 3D CAD software.

For these parts, companies usually have only 2D blueprint drawings of the parts. Those were entirely sufficient to produce the parts in days gone by with prehistoric equipment, but completely unusable for 3D printing.

And for digital inventory implementation.

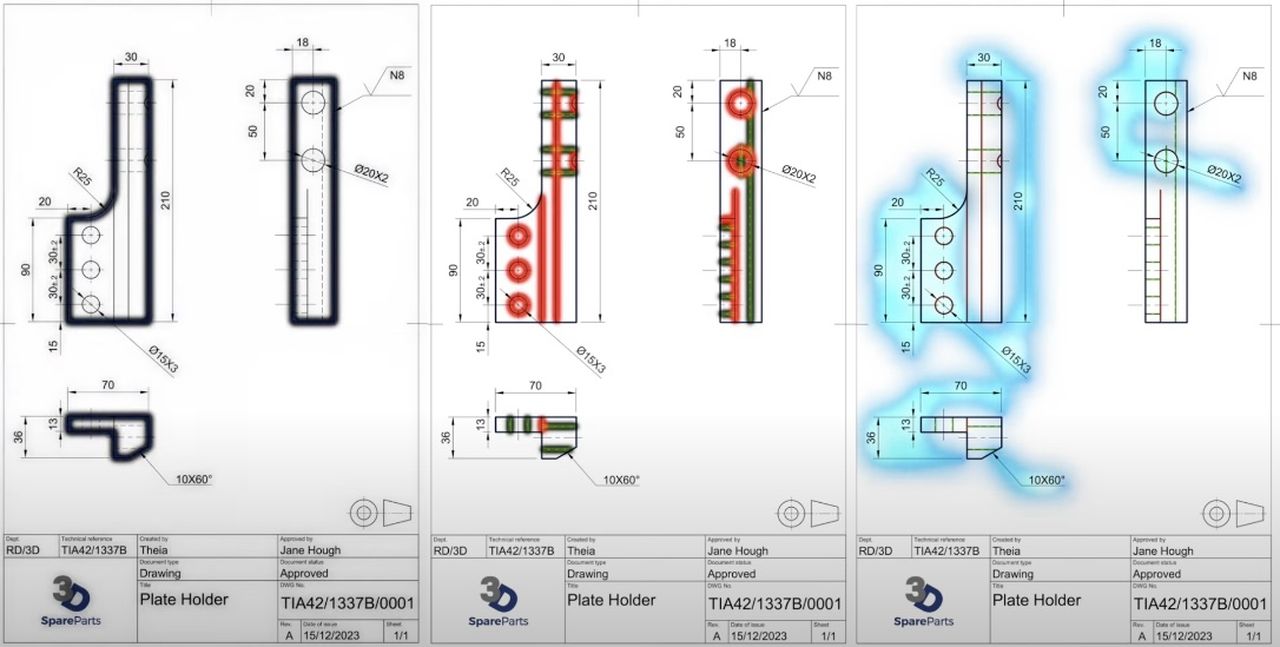

Spare Parts 3D’s latest tool, “Theia”, attempts to overcome this major challenge. It’s an AI-powered tool that’s been trained on technical drawings and is seemingly able to convert a drawing into a competent 3D model. This video shows how it works:

Spare Parts 3D explains:

“Theia is a revolutionary innovation that automatically creates a 3D model of a part from its 2D technical drawing, thus lifting a technical barrier that manufacturers have been waiting for for over 30 years. In this respect, Theia represents a major technological leap forward, enhancing the capabilities of the DigiPARTTM software. The latter can already determine, on a large scale, all technically AND economically printable spare parts, create their digital twin (digital passport) and identify a 3D printing supplier for on-demand printing, as close as possible, using the most suitable materials and processes.”

This is an impressive development, but I have some questions.

How accurate are the resulting 3D models? The example shown in the video appears to be quite good, but would a company trust the tool to produce 3D models for their production parts? My suspicion is that a company would want to extensively test the generated 3D models to ensure they are “true”.

However, that extra inspection time would have to be balanced against the cost of having a CAD engineer simply redesign the part. What if the generated part testing exceeds just redesigning the part? This may constrain the proportion of drawings that would economically be able to use Theia.

A second question arises when considering the complexity of the parts. How complex could a part be before Theia is unable to properly generate a 3D model? Most AI tools have limitations in this regard — consider making an extraordinarily long text-to-image prompt, and you’ll see what I mean. The same phenomenon might occur here.

Nevertheless, Theia is certainly going to be able to handle some portion of a company’s technical drawings, and that’s a big step forward.

Via Spare Parts 3D