Teton Simulation announced an arrangement with BCN3D to provide that company’s community with access to their powerful SmartSlice system.

SmartSlice is an extremely interesting system. It does exactly what its name suggests.

While part designers typically optimize their 3D model using FEA tools before 3D printing, there is often a loss of potential during the slicing stage.

Most slicing software simply assumes the part is a solid item to be 3D printing, and there is minimal control over what happens “inside” the 3D model. You might be able to alter the density of the infill, or the infill pattern, but not much else is possible.

But intuitively, we know that things could be optimized inside a part. We know that some portions might require more material strength that others, yet don’t have a way to control that during slicing.

Sure, there are some awkward ways to do this using exclusion zones or multiple sets of slicing parameters. But due to the difficulty of doing so, many 3D printer operators don’t bother doing much. Even worse, the operator would have to guess how to set up the print in an optimal manner.

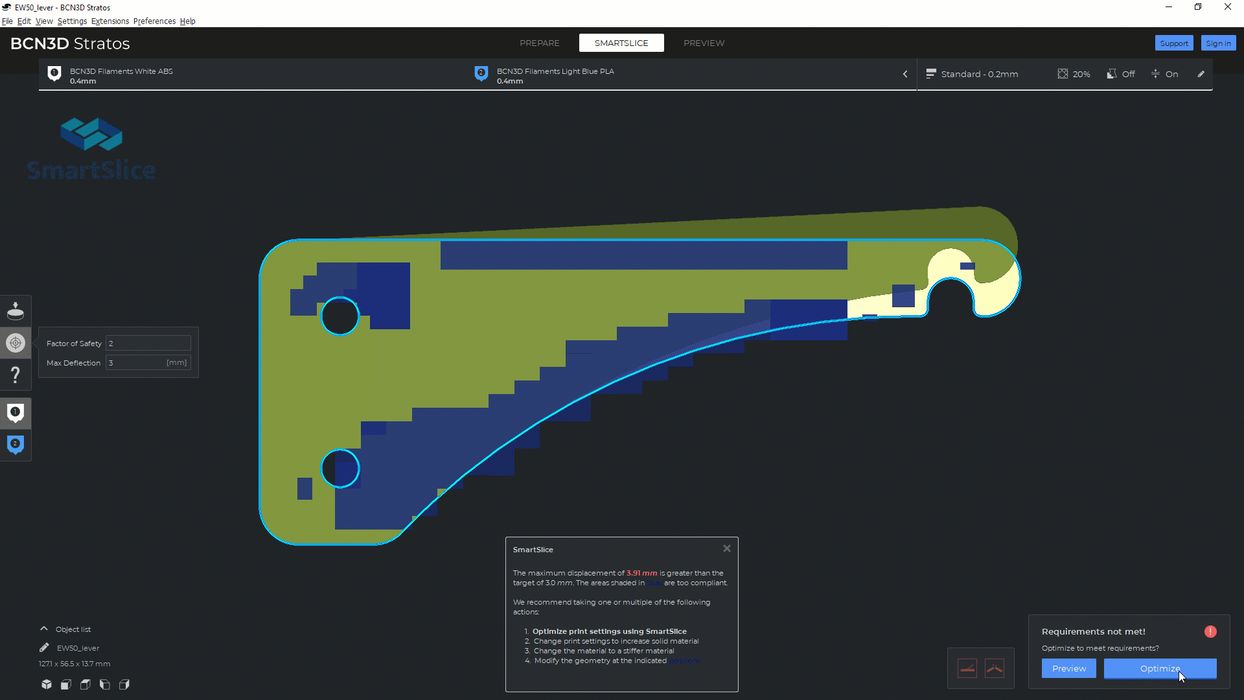

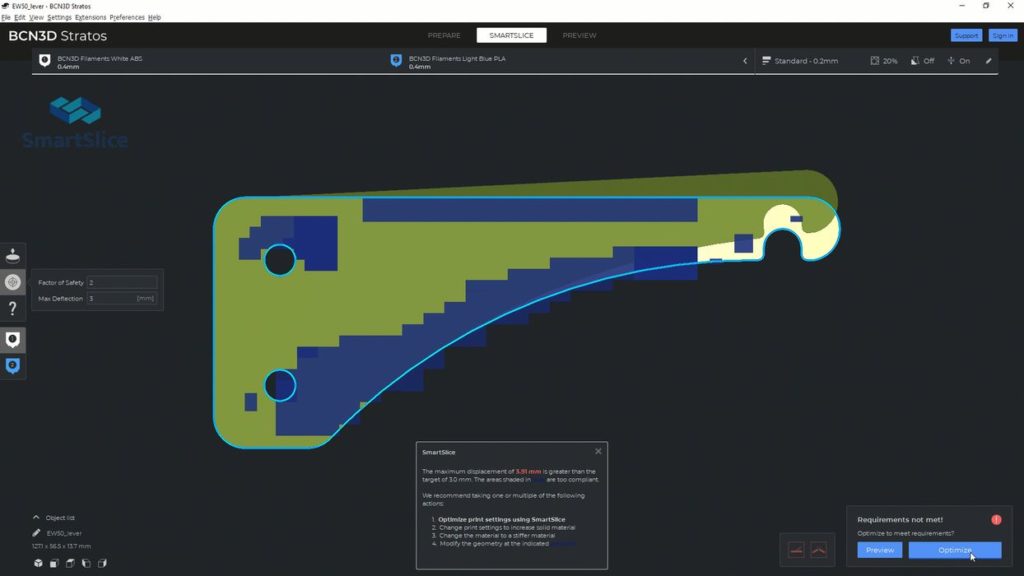

Enter SmartSlice. This tool essentially performs a finite element analysis of the part during the slicing process itself. The operator will have to supply a bit more input, but once done SmartSlice then can determine an optimal arrangement for the internals of every sliced 3D model.

This results in parts that could be lighter weight, less expensive, faster to 3D print, yet still provide all the desired mechanical function.

Teton Simulation has been marketing it through a subscription service, and has specifically partnered with a very few third parties to integrate the functionality. Previously they had partnered with Stratasys to integrate SmartSlice into GrabCAD, after first integrating SmartSlice into Ultimaker Cura.

Now they’ve partnered with BCN3D, a Spanish 3D printing company that’s been frequently in the news lately.

They’re in the news again, this time with the Teton Simulation partnership.

The partnership will have SmartSlice bundled with BCN3D’s custom-written slicing tool, Stratos, which was released earlier this year.

One of the very interesting aspects of this arrangement is that BCN3D happens to market 3D printers with dual independent extruders. This feature allows interesting print modes such as mirroring, duplication, etc., but when combined with SmartSlice could provide some very interesting results. Teton Simulation explains:

“Ultimately, that means users will obtain a higher ROI on their projects by saving countless hours and print-break cycles and will use less material, an especially useful feature when paired with IDEX technology. While savings vary depending on the part and use case, the average SmartSlice user reports 30%+ reductions in print time and material usage.”

SmartSlice will not be a free service for BCN3D clients, however. While it will be integrated, users wishing to use SmartSlice will be required to have a SmartSlice account.

But it may be that a paid account is really not an issue: given a sufficient amount of 3D printing to be done, it is entirely possible subscribers could save more than enough on their optimized prints to cover the cost of the subscription — or even more.

For BCN3D equipment operators, this is incredibly good news and a potentially huge bonus for their operations.

For Teton Simulation, it’s yet another step into a 3D print community, adding to their coverage. I have a strong suspicion they are working on additional deals of a similar nature with several other 3D printer manufacturers.

Via Teton Simulation and BCN3D