With the expiration of certain patents, one might expect to see more competition in the 3D print world, and that’s certainly the case.

There are new startups, and older companies jumping into the 3D printing market. And there are well-established overseas companies now moving into Western markets.

One of them is Shanghai-based UnionTech, who produce a line of well-established industrial 3D printers using resin technologies. They’ve been making these machines since 2003, so they are certainly mature.

Recently they’ve begun to market in the USA through a subsidiary and RP Sales America, and their sister company, RP Support for servicing needs.

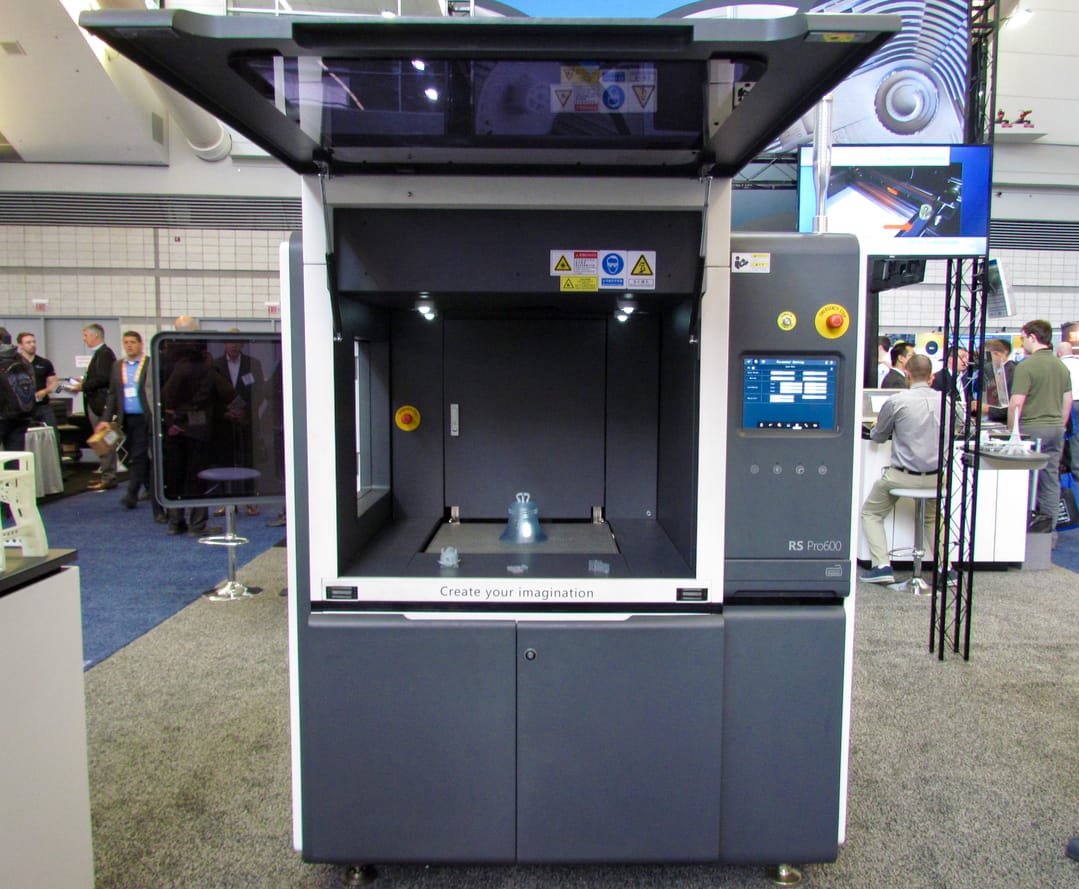

We had a close look at one of their machines, the RSPro 600, a large-format SLA 3D printer that can produce finely detailed plastic parts.

In fact, the company produce a line of four different units: three version of the RSPro in different sizes, and another unit, the EvoDent DLP 3D printer, specifically for the dental market. Prices range from USD$130K to USD$258K for the largest option, the RSPro 800. The RSPro 450 and 600 go for USD$176K and USD$205K respectively.

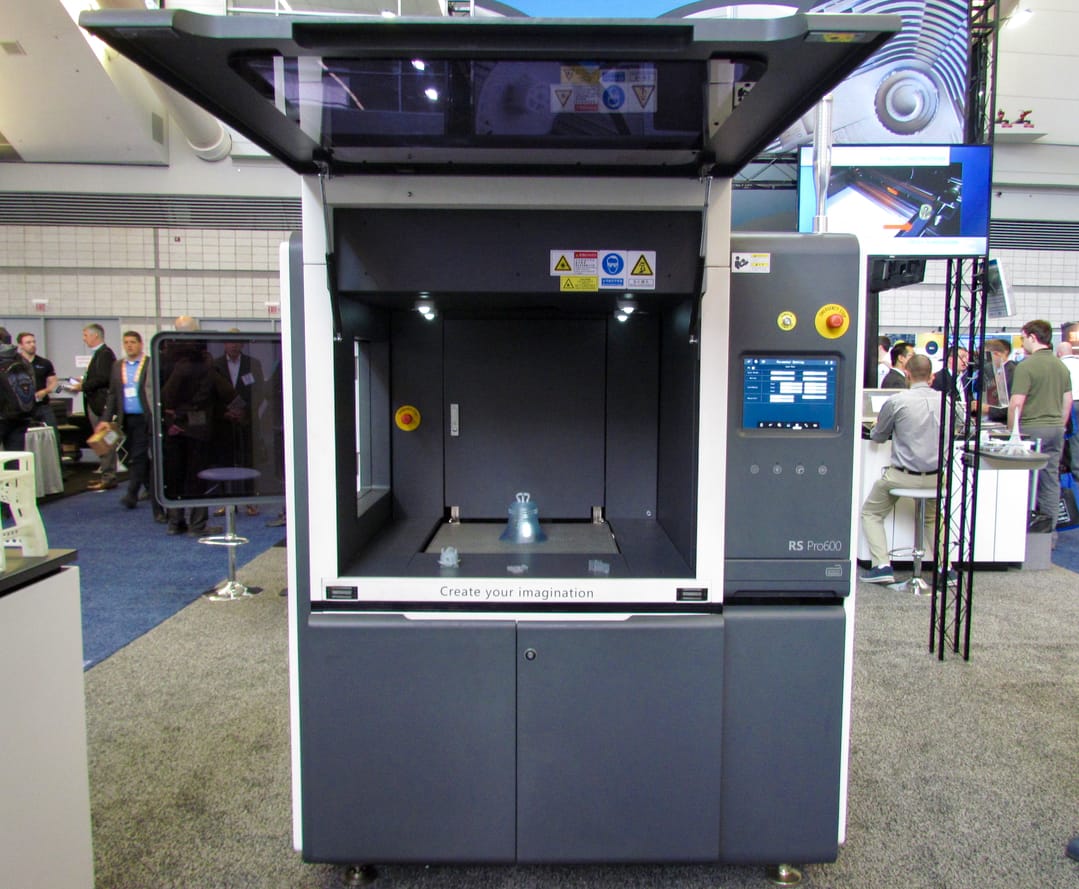

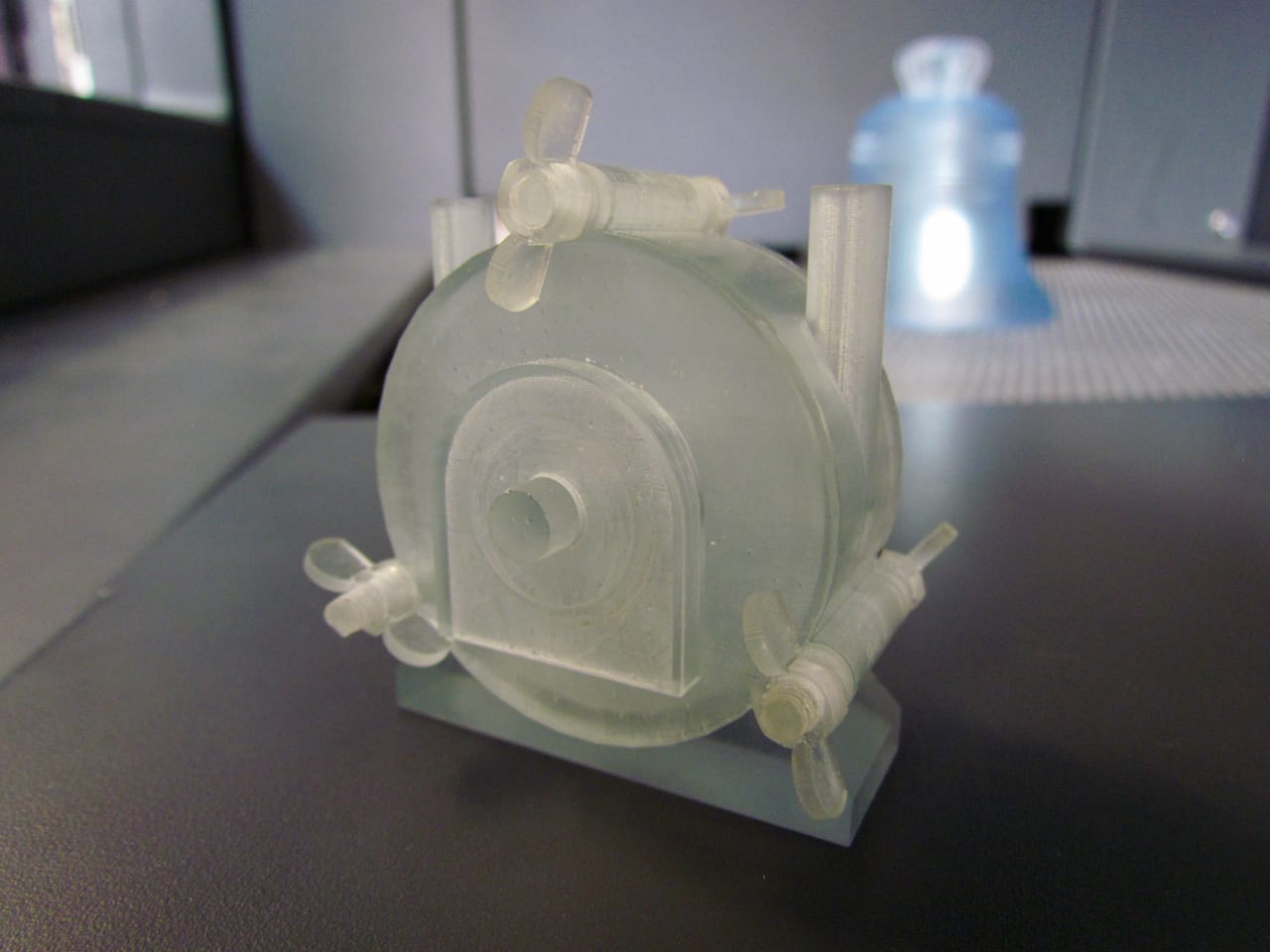

The RSPro 600 we examined has a build volume, of, you guessed it, 600 x 600 x 500mm, a tremendous size for an SLA 3D printer. Even though the machine is capable of printing larger objects, it can still achieve high resolution on prints.

The company says its accuracy of the 450 and 600 models is 0.1mm, whereas it’s a bit larger on the 800 model.

All machines are “open materials”, meaning you can use any 355nm third party resin in them, although you may have to experiment with settings to achieve optimum prints quality. This can be done through the company’s software, which conveniently offers “Easy” or “Advanced” settings options.

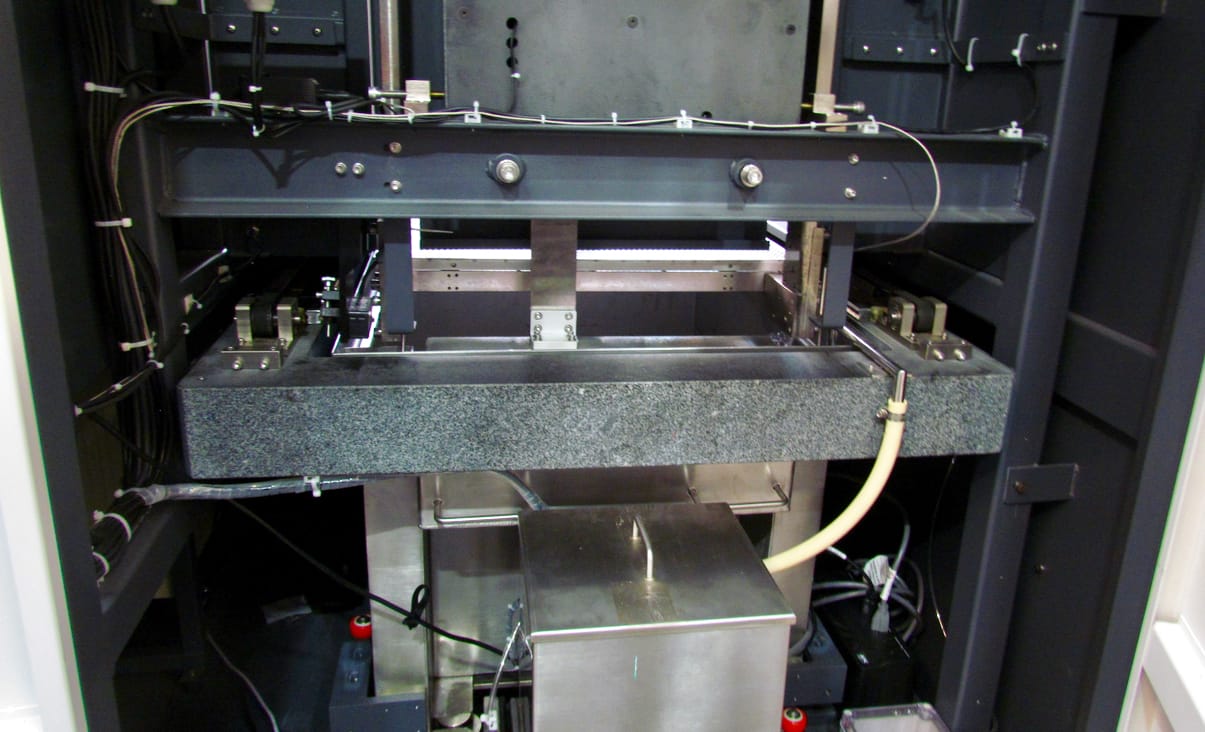

One interesting feature was the build plate, seen here from the rear of the machine. It’s actually a gigantic slab of granite, which can provide extreme stability and flatness. It’s definitely not going to warp!

The RSPro series also includes an automatic pump to provide resin refill in addition to the usual manual method. This means the machines can operate longer – and build larger parts – in unattended mode.

All machines come with one year of warranty service, and after that I presume you’d pay the standard 10-20% of original cost as annual maintenance.

Another interesting use I was shown was the ability to 3D print what they call “tetralattice”. These are positive molds used for casting. You’d immerse these in a casting material and then burn them out to form very large molds suitable for metal casting.

The idea here is that the lattice is a more efficient way to 3D print a mold than simply printing a “normal” positive object, as is commonly done elsewhere. A good idea!

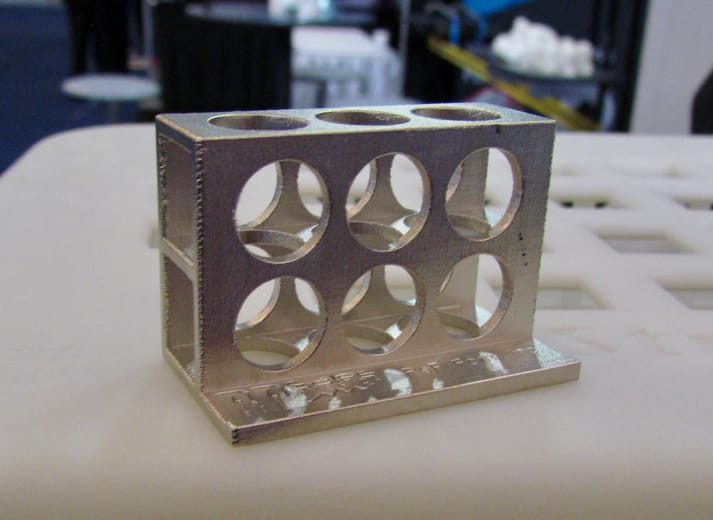

One trick that UnionTech is working on (as are a few select others) is the idea of plating their plastic prints with metal. Here we see a small object that’s been plated, and it’s quite strong – one of our staff stood on this without it breaking underneath.

But when you add all this together, I think the picture that’s painted is one of financial economy. You can get savings in three ways with these machines:

- The machine cost itself is highly competitive with established brands

- Third party materials can be used for ongoing operational savings

- Unattended mode reduces operational labor cost

It seems that if you’re in the market for a large-format SLA 3D printer, UnionTech could be a good option to investigate.

Via UnionTech