I’m impressed with not only ZRapid’s 3D printing products, but their philosophy towards materials.

The Shanghai-based company has been working on 3D printing since 1999 and has been marketing 3D printers for at least seven years.

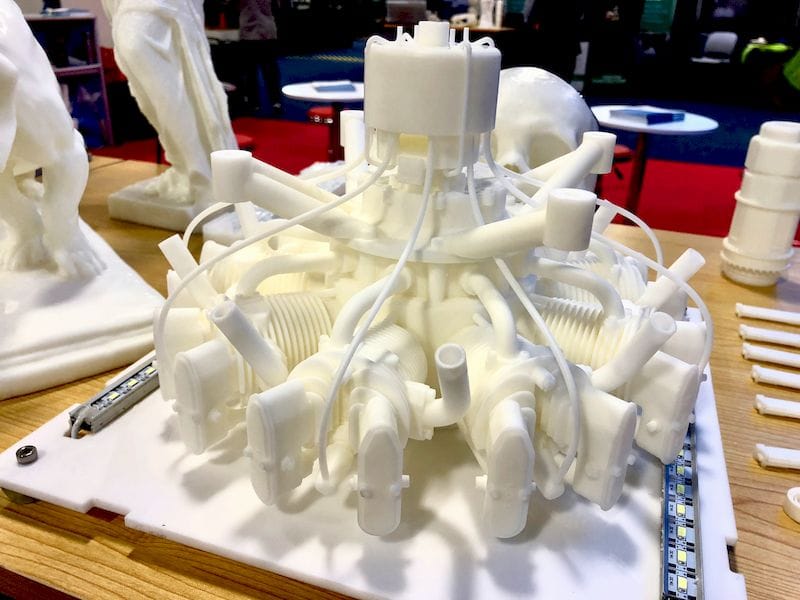

They began marketing SLA-style resin 3D printers, but have since branched out into multiple 3D printing processes and offer a full range of industrial 3D printers, ranging from SLA to SLS to even 3D metal printers.

One impressive stat is their iSLA 1100 3D printer, a resin machine that has an enormous resin tank that can accommodate 150kg (yes, that’s 330 pounds) of resin. This makes the machine capable of 3D printing very large size objects in the 1000 x 1000 x 600mm build chamber. That must be one of the largest SLA volume machines readily available for purchase today.

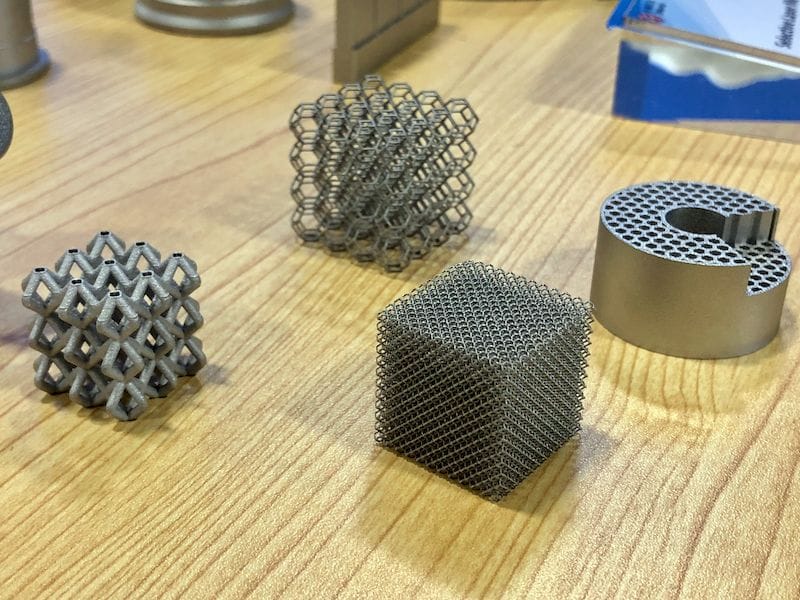

The company introduced 3D metal printers in late 2016, so they’ve now had almost two years of experience working with clients on this technology. The metal machines use the typical laser / powder bed approach, so their operation will be familiar to most 3D metal printer operators.

The pricing on their 3D metal printers is quite good when compared to other alternatives offering similar technology: priced from USD$150K to USD$350K, the machine has a healthy build volume of 300 x 250 x 350mm and can produce objects up to 75kg in weight.

They now also offer an “FMS” 3D printer, which is similar to SLS in that a laser selectively sinters a bed of powder, but in this case the powder can be ceramic or metal powders with a binding agent. A CO2 laser sinters the powder layer within a nitrogen-filled chamber. This creates composite objects with differing properties, and is a bit different from traditional SLS 3D printing.

For all of these machines – and ZRapid now seems to market no less than twelve different machines – the company offers a reasonable selection of materials in the form appropriate for the equipment.

What’s a bit different is that they have a philosophy of open materials. There is no requirement to use their materials, although I suspect they may offer a more reliable result through the use of company-provided print profiles.

You are entirely able to use any feasible material you can lay your hands on for use in their equipment. In fact, they say that their software is “open control” and “allows users to do things”. This creates a very good environment where users can achieve two key benefits.

First, they can potentially lower the price of materials by sourcing them from better suppliers, or from those nearer, thus reducing shipping costs of heavy metal materials in particular.

Secondly, the open materials philosophy allows users to experiment with different materials, or even compose their own hybrid materials by mixing different substances together. Of course, this will no doubt require an amount of experimentation with 3D printing parameters to obtain successful 3D prints that match the engineering needs, but it is a way for companies to differentiate their products from others by using unique materials.

One question you might ask is why you have not seen machines from ZRapid more often. That’s because their sales network is not particularly well-established in the west, at least not yet.

We’re told the company is indeed hoping to perform a significant expansion into western markets and at this time they are seeking resellers for Canada, Europe, USA and South Asia. This could be a huge opportunity for some resellers looking for an extensive set of new products to market.

Via ZRapid