A new 3D printer filament product will open up some interesting thermal applications.

TCPOLY’s Ice9 line of filaments has a property that is not present in almost all other 3D printable filaments: thermal conductivity. There are many filaments on the market today including electrical conductivity, but this is the first that I’ve seen focus on thermal conductivity.

Ice9 is produced in several base materials, including nylon, TPU and PEKK, with nylon and TPU also available in electrically-insulating versions.

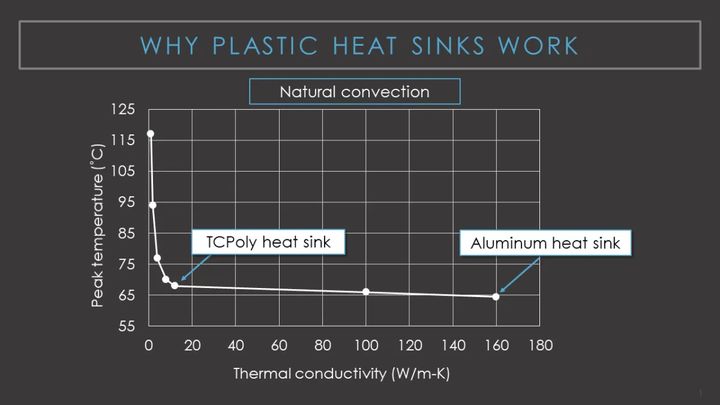

TCPOLY claims the thermal conductivity of Ice9 is similar to aluminum, as seen on this chart. That’s quite a claim.

If this is true, and I’ve heard anecdotally from users that Ice9 does indeed work pretty well, this could be very interesting indeed. One story had someone 3D printing prototype heat sinks, and its performance was close to that of the aluminum equivalent object.

Why would you need to use thermally conductive filament? It turns out there are multiple applications of of this technology.

Consider the case of an embedded electronic chip that’s been sealed inside of a 3D printed part. The chip will generate heat, which normally dissipates in the surrounding air. However, if the chip is embedded, there’s nowhere for the heat to go other than the encasing plastic.

If that thermoplastic doesn’t sufficiently distribute the heat, it will accumulate and potentially reach the material’s glass transition temperature: the structure will sag and distort.

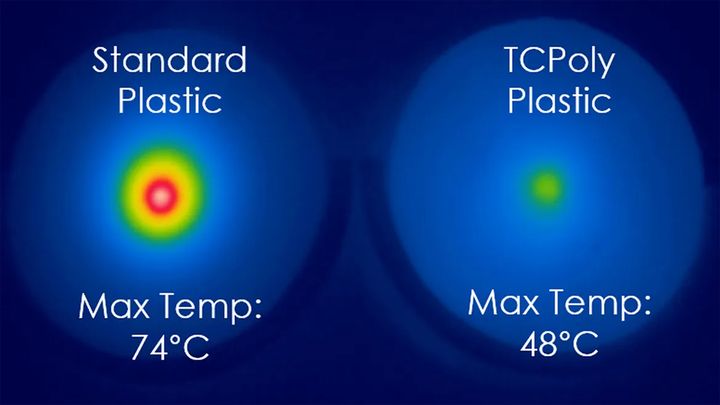

On the other hand, if the material could channel away the heat the failure would not occur. Take a look at this chart from TCPOLY showing how an embedded component maintains a stable temperature of 48C due to Ice9’s thermal capabilities, versus the standard poorly conducting material that keeps the component at all 74C.

Since chips tend to fail at higher temperatures, this could enable more reliable, long-lived and functional embedded electronics applications.

This effect is most interesting with TCPOLY’s PEKK option, which offers a heat deflection temperature of 270C. Using TCPOLY PEKK one could design structures that might otherwise be possible only with metal.

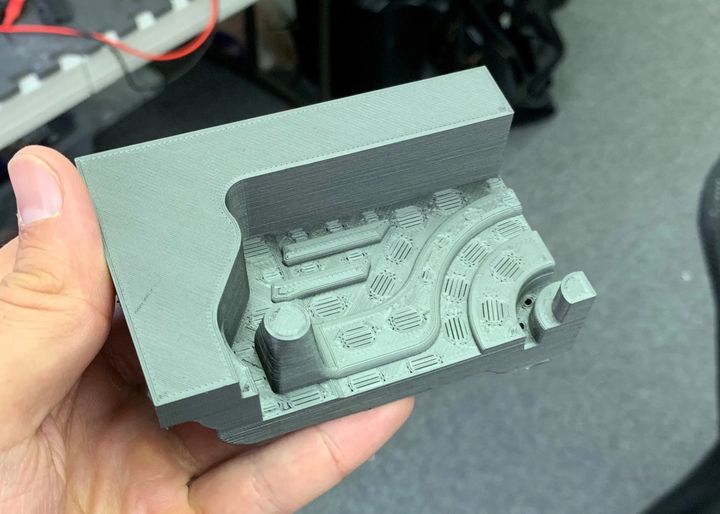

Heatsinks and heat exchangers are another possible application of this unusual set of filaments. Here you can see a 3D printed Ice9 heatsink that just wouldn’t work with a standard thermoplastic:

In some cases the thermal conductivity of Ice9 would allow a designer to develop an end-use heatsink made of polymer instead of metal. The ability to make heatsinks and exchangers of unusual geometries with quick-to-use materials could be of great interest.

In other cases it would be possible to prototype a heatsink eventually to be made in metal. This would allow studies of thermal flow through the structure on a rapid iterative cycle, faster than one could perform if prototyping in metal.

TCPOLY cites molding as another potential application. In this scenario, an Ice9 mold would be able to carry away heat far faster than typical 3D printed molds. This could speed up the casting process, and might allow the mold to survive for many more casts.

If you’re designing 3D printed devices and have been stymied by thermal issues, Ice9 might be the solution.

Via TCPOLY