3D Systems and Desktop Metal announced notable corporate acquisitions.

3D Systems and Oqton

3D Systems announced the acquisition of California-based Oqton, a provider of an intelligent, cloud-based manufacturing platform. Termed a “Manufacturing Operating System”, the service provide a number of technologies and workflows related to additive manufacturing.

It’s a highly flexible system that can be used to rapidly develop new and effective additive manufacturing workflows. For example, last year we saw a demonstration of a “quality control” prototype with an incredibly simple operating mode: a technician simply tossed a random part into a chamber, where it was instantly 3D scanned (regardless of orientation), matched against a CAD database and checked for tolerances. A red or green light appeared to indicate the results.

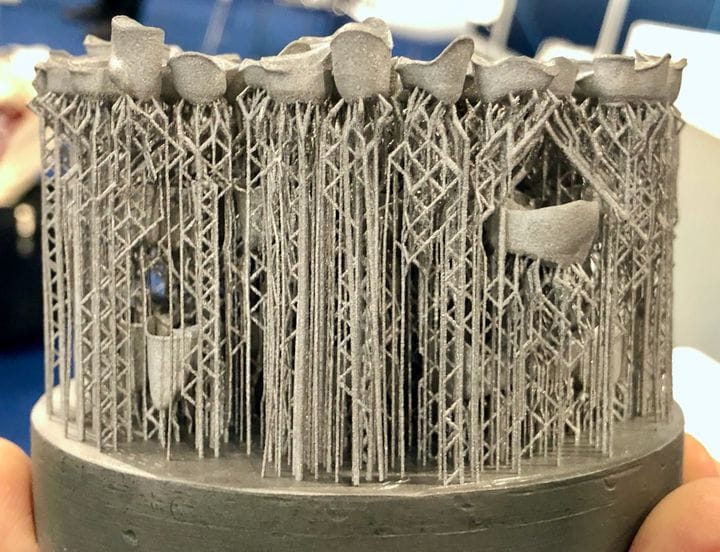

Similarly, the company also showed us how their job preparation features were able to generate highly complex support structures for metal 3D prints that actually enabled stacking of objects in way I had not seen previously.

Those are but two interesting cases from Oqton’s feature set, and there are many more. Note that Oqton is a Manufacturing Operating System, and its capabilities go well beyond just additive manufacturing.

Soon, it will all belong to 3D Systems, who intend to integrate it into their industrial and healthcare products. 3D Systems CEO Jeffrey Graves said:

“The Oqton MOS fills this market need by seamlessly leveraging enterprise information and data in the customer’s current ERP, MES, PLM, and CRM systems, as well as the full range of shop floor manufacturing operations and software. The use of APIs to create ease of linkage between these systems is a distinctive attribute of the Oqton MOS. This allows customers to use their choice of manufacturing and automation equipment on the shop floor to meet their unique factory needs. Oqton’s cloud-based MOS solution, with its embedded AI and machine learning capabilities, then optimizes and automates these manufacturing elements in a manner that is not available today. This solution lowers the barrier to adopt AM in a transformative way – through the integration of the solution AND the optimization of the production workflow.”

3D Systems specifically intends to integrate their existing tools, such as 3DXpert, 3D Sprint, Geomagic and others into the Oqton MOS.

This acquisition strongly aligns with 3D Systems strategy for industrial and healthcare sector manufacturing. There is no doubt that the Oqton platform will become the “spine” of 3D Systems manufacturing offerings in the future, and could enable them to succeed notably in manufacturing.

3D Systems did not mention anything resembling “the company will continue to operate independently”, so I assume it will be truly absorbed by the much larger 3D Systems entirely.

One question outstanding is the fate of other Oqton clients. Today Oqton boasts of serving companies including EOS, Sisma, Sandvik, Trumpf, HP, PRODWAYS, and Stratasys. These are all competitors of 3D Systems, who certainly intends to use Oqton as a strategic backbone. 3D Systems doesn’t say, but it may be that these competitors may at some point have to migrate to another MOS, or build their own.

You can see how strategic this move will be for 3D Systems.

Desktop Metal and Aidro

Meanwhile, Desktop Metal has acquired Aidro, an Italian manufacturer of hydraulics. This might seem a bit strange at first: why would a 3D printer manufacturer buy a hydraulics company? Let’s look at the background of Airdro, from Desktop Metal:

“Founded in 1982 and based in northern Italy, Aidro has almost 40 years of experience in the design and production of valves, manifolds, and various hydraulic components and fluid power systems. Aidro offers best-in-class expertise in design for additive manufacturing, including finite element analysis simulation and topology optimization techniques. Aidro engineers leverage these technical capabilities to redesign traditional hydraulic components for AM production using complex geometries to reduce weight, save space, and consolidate multiple components into one, eliminating assembly and welding requirements. Hydraulic components produced by Aidro using AM improve performance versus conventional manufacturing by optimizing flow channel placement and geometry to increase flow capacity and decrease pressure drops.”

So it’s pretty clear that Aidro is quite expert at AM in the hydraulics business, and seems to have found a “killer app” for with complex hydraulic designs.

Desktop Metal CEO Ric Fulop said:

“This acquisition advances Desktop Metal’s strategy to support our major OEM customers with proprietary design and application know-how as well as through a combination of best-in-class AM products and high-value parts production across killer applications for AM 2.0. Aidro brings a talented team with decades of experience in hydraulics and fluid power systems and a passion for leveraging AM to deliver performance advantages to their customers. We’re excited about the acquisition and look forward to advancing AM 2.0 for high-volume production of hydraulics, valves, fluid power systems, and many more end-use parts in development with Aidro.”

I’m intrigued by this move, and it may be more subtle than imagined at first glance.

The interesting part is that this is a company that is using AM to produce parts in an effective manner. This is quite different from manufacturing the equipment and materials to produce those parts, which is what Desktop Metal has been doing up to now. This acquisition puts Desktop Metal in the position of a user of the technology, rather than a maker of the technology as they have been.

That could be an incredibly good move for Desktop Metal, as they could be shortening the distance between technology and application. In other industries this has been done for decades, and it’s called vertical integration.

However, vertical integration often involves the product maker buying up the suppliers, both material and technology. Here we have the technology component buying the application in a kind of reverse vertical integration.

Nevertheless, vertical integration can be a very successful move. The part makers are tighter to the technology, enabling more intense and unusual use of the technology. We could see even more advanced hydraulic components emerge from Aidro.

More importantly, this acquisition could be a signal that Desktop Metal is open to buying manufacturers of other products in a similar way. They could have a strategy to surround their technology core with an array of industrial users that drives their revenue in a significant way.

Desktop Metal has been on a tear lately, buying companies at every turn. This one, however, seems quite different.

Via 3D Systems, Oqton, Desktop Metal and Aidro