COBOD revealed one of their construction 3D printers is being used on a Habitat for Humanity project.

If you’re not familiar with Habitat for Humanity, you should be. The non-profit organization has been around for many years and provides an ability for low-income folks to finally own a home of their own. The key to their process is a mixture of community support and “sweat equity” by the receiving homeowners. In other words, they help build their own habitat.

The approach works because the homeowners have a deep stake in the project because they’re the ones doing the work, or at least some of it.

One of Habitat’s key supporters is none other than former US president Jimmy Carter, who periodically appears out of nowhere at Habitat build projects to lend a hand. Pretty impressive for a 90+ year old!

The latest project does not involve Carter, but it does involve 3D printing in a way that has not previously been done for Habitat projects. COBOD’s equipment has previously been used on a project in Florida earlier this year, and several places outside the USA.

The new project takes place in Tempe, Arizona, where a single 3D printed home will be constructed.

The work is being undertaken by 3D Construction USA, a joint venture between COBOD and PERI, a German firm specializing in concrete and formworks. COBOD has worked with them on prior projects, so the work in Tempe is no surprise.

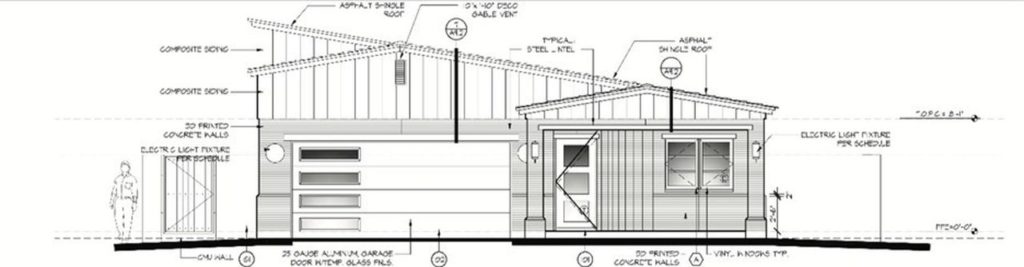

The home design specifies a floor space of 1,722sf (150sm), which is actually quite large for a 3D printed building. Most 3D printed buildings are relatively small in size as they tend to be experiments or demonstrations. However, this project involves a building that will literally become someone’s home.

From the images provided to us by COBOD, it appears that the project could involve a mixture of in-place 3D prints using their BOD2 construction 3D printer, as well as separately 3D printed fixtures as seen here.

Jason Barlow, CEO of Habitat central Arizona, said:

“This is really a moonshot opportunity for Habitat for Humanity Central Arizona. When we consider the housing issues facing Arizona, the need for affordable homeownership solutions becomes clear. If we can deliver decent, affordable, more energy-efficient homes at less cost, in less time, and with less waste, we think that could be a real game-changer. Just think of the implications.”

For Habitat, this is an experiment to test whether the technology fits with Habitat’s goals. Certainly higher-speed delivery and lower cost are attractive, but for Habitat there may be other factors at play.

One of Habitat’s key elements is the work to be put in by the future homeowners, as explained above. How does this work when you are 3D printing the home? Doesn’t the 3D printer do all the work?

In fact, it does not. We’re really not 3D printing a home; instead we’re 3D printing the concrete portions of a home. The remainder of the project, including plumbing, HVAC, electrical, windows, flooring, finishes and decorative elements all must be done using traditional approaches. That’s why Habitat said the project will be ready in August/September rather than “tomorrow”.

3D printing entire homes in 24 hours is a fictional concept that occurs only in sensational news stories.

That’s why there will indeed be plenty of work left to do for the the homeowners, and Habitat’s operating principles will not be violated here.

I’m interested to see how this project proceeds. If it succeeds, then we may see COBOD equipment appear at more Habitat projects.

Finally, Habitat for Humanity is an incredibly generous and beneficial organization. If there’s a project taking place in your area — and there likely is — please consider offering them some assistance.

Via COBOD, PERI and 3D Construction USA