The first massive 12-laser NXG XII 600 3D printer destined for North America is on its way to Divergent.

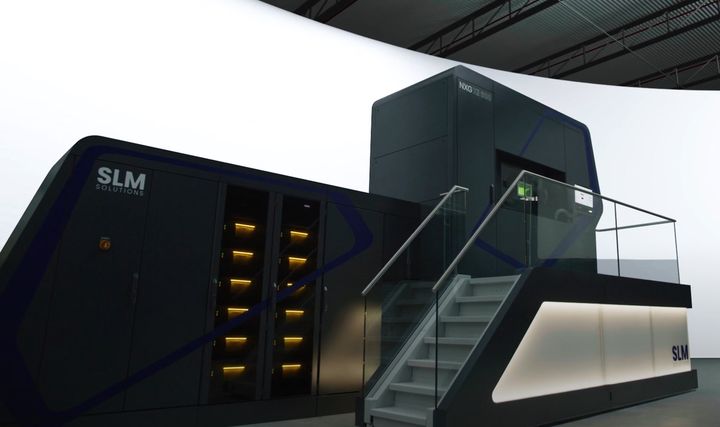

NXG XII 600

In November, SLM Solutions introduced its latest industrial additive manufacturing behemoth. The NXG XII 600 is a standout among metal 3D printing systems, carrying such we-had-to-look-twice specs as:

- Twelve 1000Wlasers

- 600 x 600 x 600 mm build volume

- Build rates of 1000ccm/h

- Up to 10,000kg annual metal part 3D printing capacity

For more on the mechanics of the system, read our introduction to the NXG XII 600 here.

NXG XII 600 Usage

The 3D printer sounds fantastic. But in this industry, we’ve all had more than enough too-good-to-be-true claims to last a lifetime. So is the 12-laser, 20-times-faster system feasible?

It seems to be. SLM Solutions is hitting strong with customer feedback from the start.

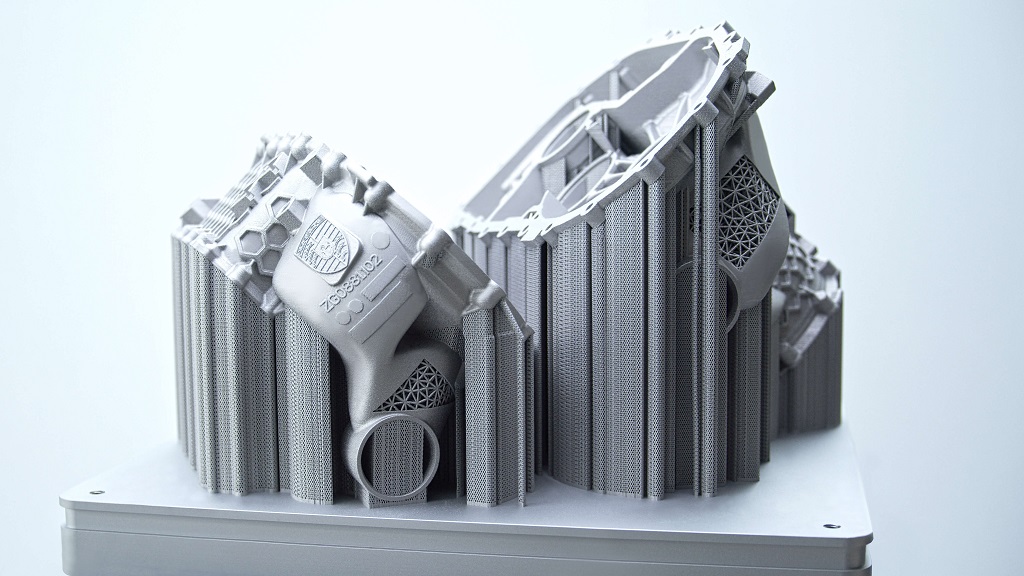

Last week, the company released a look at a proof-of-concept 3D print. Porsche created a complete E-drive housing using the new additive manufacturing system. Not just a pretty part for a fancy car, the E-drive housing demands quality; such a part faces demands including:

“A permanent magnet motor with 800 volt operating voltage delivers up to 205 kW (280 hp). The downstream two-stage transmission is integrated in the same housing and drives the wheels with up to 2,100 Newton meters of torque. This highly integrated approach is designed for use on the front axle of a sports car.”

SLM Solutions further reveals:

“The E-drive unit measures 590 x 560 x 367 mm and was built in only 21 hours on the NXG XII 600.”

The part used most of the build volume, actually testing the limits and the claims — and seems to have been a success.

“This new manufacturing technology is technically and economically interesting for us. Possible use cases are especially prototypes in the development phase, special and small series production as well as for motor sport and classic spare parts,” said Falk Heilfort, powertrain development engineer of Porsche.

SLM Solutions has added a name-dropping “customer voices” series of video testimonials about the NXG XII 600, including input from Porsche, 3DnA, Safran, and Siemens Digital Industries.

NXG XII 600 Shipping

This week SLM Solutions has announced another big step for the monster metal system: it’s shipping internationally.

SLM Solutions North America is now facilitating the shipment of the first new system outside of Germany. While the company can’t share the number of systems ordered, they have unveiled the first North American customer to see an installation.

Divergent, which has been working to upend automotive production including views to create the first 3D printed supercar, will be the lucky customer to see such an early installation. SLM Solutions and Divergent have been working together for some time now, highlighting their partnership over the last year.

“It has been an exciting and productive journey and we are looking forward to delivery of the first of those machines to Divergent’s LA Factory — where the world’s first end-to-end digital manufacturing system is in industrial-scale operation,” said Divergent Founder and CEO Kevin Czinger.

The automotive market has long been an additive manufacturing stronghold. With customers like Divergent and Porsche leading the way for SLM Solutions’ latest multi-laser beast of a metal 3D printing solution, the company is positioning itself nicely for real-world usage.

Multi-Laser 3D Printing

There’s something of a “battle of lasers” happening now in 3D printing. On the heels of the 12-laser introduction, additional 8-laser launches put additional fire to the idea of multi-laser additive manufacturing. I remember just a few years ago when a dedicated display at Formnext highlighted the “wow” factor of a 4-laser system.

SLM Systems is well poised as a player in this battle. The company that originated SLM 3D printing itself was also the first OEM to bring multi-laser technology to the market. The aggressive timeline of November launch and December international shipping underscores the team’s focus.

Indeed, the company tells us now:

“Committed to its upward growth, the company is laser-focused on the future and leading the industry in metal additive innovation.

It’s not just about the number of lasers but the technological innovations that will increase productivity (e.g. reduced fire-to-fire time, zoom function, plus the well known bi-directional recoating,…).

While some market players battle for a high number of lasers, SLM is focused on increasing productivity and thus reducing cost per part which now positions AM as an attractive alternative and well suited element of today’s and tomorrow’s supply chains.”

We should be hearing more updates about the NXG XII 600 installation early in the new year.

Via SLM Solutions, SLM Solutions, and Divergent

Awesome post.