When we last saw 3NTR, the company had begun marketing a very powerful high temperature 3D printer.

Recently we encountered them once more and saw machines that had undergone some very subtle but strong improvements.

Even though a 3D printer may be able to 3D print high temperature materials, that doesn’t mean it’s a perfect machine; there are many other aspects to successful 3D printing that must be accounted for, and that seems to be what Italy-based 3NTR has been working on.

Let’s review their recent improvements.

First, they’ve been working on new material options. They have a new formulation for a nylon / carbon fiber filament that can be used to print very stiff parts that offer very good heat resistance.

3NTR now also offers a water soluble support material, which should make it far easier to 3D print objects with complex geometry. Just dunk the completed print in a tub of water and wait for the support material to dissolve. Now you can make high temperature parts with complex geometries.

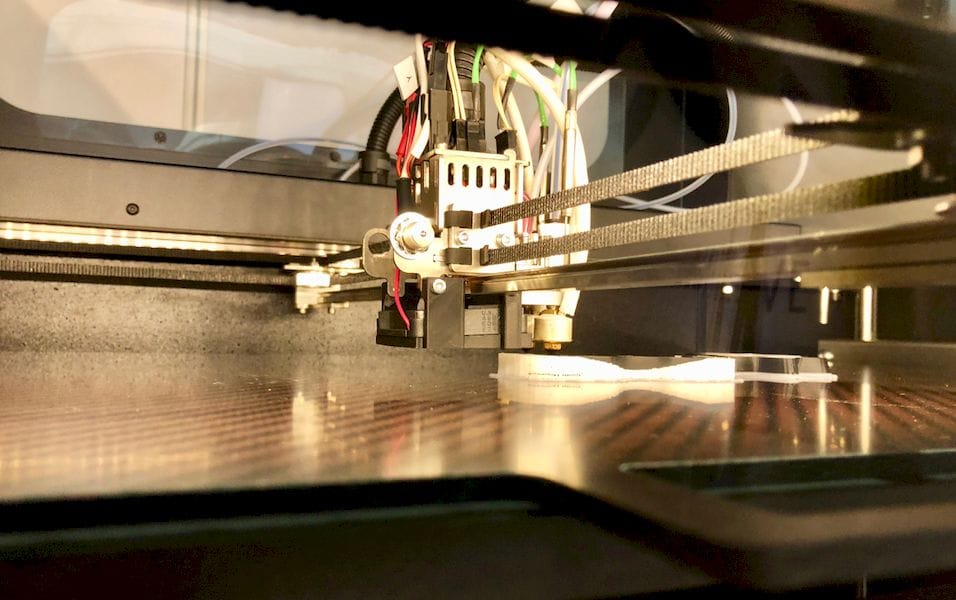

Inside the machine, we find the print surface has been optimized: it’s now easily removable, and held down by magnets. Made from carbon fiber, this springy bed has a PEI surface for easy adhesion, and prints can be quickly removed by twisting the bed after cooling down. Cooling obviously is much faster because the prints (and print bed) are outside the warm printer.

The 3NTR machines now sport new hot end nozzles that have had a special treatment that increases heat exchange. Now they apparently transfer heat as fast as copper, yet are still as strong as steel.

3NTR has also improved their software over the past year by building a new printer management system on top of the popular KISSlicer. They’ve integrated their own specific features into SSI, the “Smart Slicer Interface”, including abilities to choose printers, nozzles, materials, etc.

The now highly competitive market for high temperature professional 3D printers seems to be heating up, with companies like 3NTR offering incremental improvements to their systems. It’s never been a better time to acquire a high temperature system.

Via 3NTR