The two types of 3D printer filament, 1.75mm and 2.85mm: which is better?

Today virtually all filament-based 3D printers use either 1.75mm or 2.85mm diameter filament. But why is the so? Why weren’t other sizes used? Why are these specific diameters the standards of today?

The answer turns out to be historical.

Stratasys 3D Printer Filament

The original filament-based 3D printers were, of course, from Stratasys. The company invented the FDM process in the 1980s, and due to patents they were the exclusive user of 3D printing filaments for many years. Their proprietary filament had, and still has, a diameter of 1.78mm.

I don’t know the specific reasons why Stratasys chose this particular filament format, but it’s been very successful for them, and continues to be so. However, due to its proprietary nature no one else uses it, aside from a few companies producing “clone” materials for Stratasys equipment.

3D Printer Patent Expiry

In and around 2008 the initial Stratasys patents on the FDM 3D printing process began to expire, making it possible for others to produce machines using a similar process. Of course, they could not call their processes “FDM”, as that was and remains a trademark owned by Stratasys. Today such equipment is said to be “FFF” for fused filament fabrication, even though it is virtually identical to FDM in concept.

These desktop machines of 2008-2010 were mostly developed by small startups and even hobbyists. Some, like Ultimaker and MakerBot, eventually grew into large corporations. Others, like Solidoodle, failed along the way.

Building a new device in a market that had no idea about 3D printing was quite challenging, and especially so regarding materials. The idea was to have many people using the new desktop 3D printers across the world, but there was a significant issue: materials.

At that time the plastics providers and chemical companies were either unaware of or ignored the nascent 3D printer industry, likely due to its incredibly small size and uncertainty over its future. Why invest into an industry that doesn’t yet exist? It should be proven first.

Early 3D Printing Materials

Since no providers made materials specifically designed for 3D printers, the only option at the time was to repurpose commonly available materials. This left 3D printer designers and operators with extremely limited choices in both material type and format.

It was generally decided that ABS welding wire would be the best option. ABS was a material that could be relatively easily 3D printed (although we now know better). Typically this material was available in 3mm diameter form. However, the consistency of the filament diameter throughout the spool was poor, as that didn’t matter as much for the welders who were the actual target for the product.

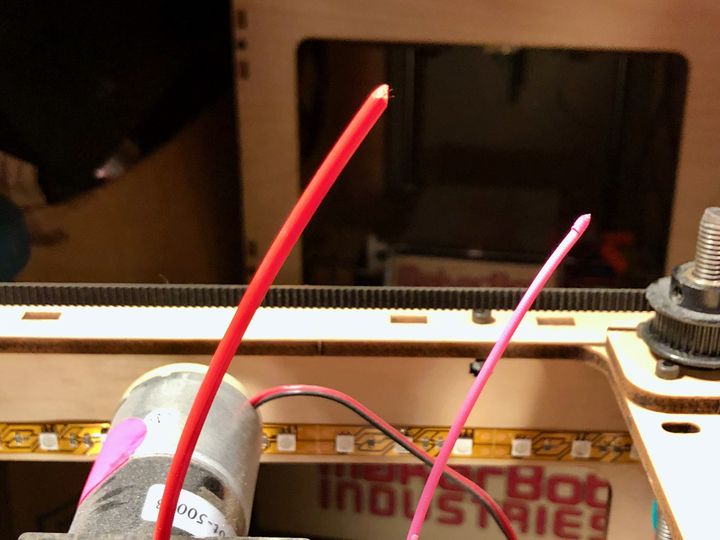

Thus the first desktop 3D printers used 3mm filament. My original MakerBot CupCake 3D printer still has a segment of this material sticking out of the top, while it waits to be reactivated. It will have a very long wait, I am afraid.

The Appearance of 2.85mm 3D Printer Filament

A problem was quickly realized with 3mm filament: it was too big.

While the early 3D printer designs simply fed bare filament into the direct drive extruders, new designs required the use of feed tubes. In particular, the Bowden extrusion design made this mandatory, as retractions and pushes required a fixed-size tube to maintain pressure throughout the filament path.

Unfortunately, many of the commonly available tubes had an inner diameter of 3mm. This meant that 3mm filament have a difficult time sliding smoothly through the tube, and this caused jams. I recall people discussing methods of lubricating filament for this reason, at the time.

Sensible thinking took hold and the idea of a slightly smaller filament size emerged. The industry quickly settled on 2.85mm, which fits well into commonly-available 3mm inner-diameter tubes. Fortunately, there were enough plastics manufacturers paying attention at that time to actually manufacture filament of that format.

The Emergence of 1.75mm 3D Printer Filament

The industry was also at that time settling on a standard nozzle diameter of 0.4mm, which was smaller than some of the earlier nozzles. Some thought that a smaller diameter filament would complement the smaller nozzle as less volume flow would be required. Someone proposed 1.75mm diameter filament and the producers followed along.

Soon 1.75mm format filament grew in popularity and has now become by far the most popular filament format available.

Comparing 1.75mm and 2.85mm 3D Printer Filament

But which filament format is best? Each filament has some advantages.

1.75mm filament can provide these benefits:

- Widest possible choice in material types and colors

- Widest availability

- More flexibility at room temperature

Meanwhile, 2.85mm filament can provide these benefits:

- Stiffer filament for Bowden-style extrusion

- Faster delivery of material for rapid extrusion

I believe one of the factors that pushed many machine designers toward 1.75mm filament was the emergence of PLA as a standard material.

PLA has a nasty habit of becoming fragile after being exposed to the atmosphere. While many today take the storage of 3D printer filament very seriously, this was not the case years ago, where half-used spools would lay open on many a workshop bench. Over time the PLA would become so fragile it would tend to snap if twisted. Sometimes it would become so fragile it would crack during a 3D print job, causing a print failure.

This was especially so for the fatter 2.85mm filament format: the increased rigidity of thicker filament would cause frequent cracking on an older spool, particular towards the end of the spool, where its natural tight curve around the spool hub could not survive being bent into a smoother filament path. I can’t tell you the number of times I had 2.85mm PLA crack in my jobs.

But this effect happens far, far less on 1.75mm filament spools because the filament is more able to bend when unspooled. This, I believe, is the major reason for the popularity of the 1.75mm format.

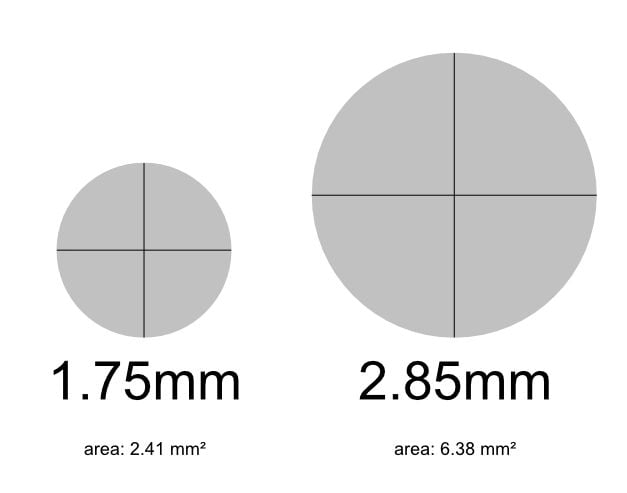

Another factor is the volume of print material during printing. As you can see at top, the 2.85mm format provides a far greater area of material. To deliver a given amount of material, the extruder would turn 2.6X slower if using 2.85mm filament. Depending on the accuracy of the extruder’s stepper motor, this could very slightly affect the precise control of material flow. While this may have been a concern years ago, I am not certain this is still the case.

Why Does 2.85mm Filament Survive?

In spite of the advantages of the 1.75mm format, 2.85mm filament is still widely available. There are several reasons for this:

- Some manufacturers have committed to the format for historical reasons and it would be quite disruptive to their ecosystem to change at this point

- Certain Bowden-style 3D printers do work better with more rigid filament as provided by the fatter format

- Use of flexible filament is easier if it can be even slightly more rigid, as it must be pushed into the hot end. A floppy thin filament may fail

- More industrial and professional use of 3D printers has reduced the use of fragile PLA and increased use of materials more usable in 2.85mm format

As far as I’m concerned, the major reason to use 2.85mm filament today is simply that it happens to be the format used by the 3D printer you acquired. As long as those vendors produce 2.85mm format 3D printers, the format will survive.