We often hear people asking the question “How big an object can you print on that thing?” The answer depends on which personal 3D printer you’re talking about, because they vary in size considerably. The public’s thinking seems to be “bigger is better”. We’re not so sure.

Not only do personal 3D printers vary in size, but they also vary in price. Buyers may choose anything from the highly affordable open source projects made from commonly available parts to the more expensive fully assembled commercial units.

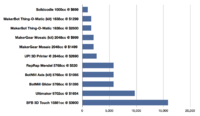

But how much do you get from each of these personal 3D printers? How big can you print with them? Theoretically, it’s the size of the build envelope, which is the product of the maximum dimensions of each of the X, Y and Z axes. We took a quick look at some of the more popular options and found the following (click for larger view, axes in mm, volume in cubic centimeters):

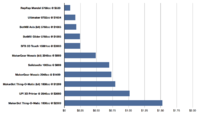

The huge variation in build envelope size is apparent, with the largest in our study being the BFB 3D Touch and the smallest the recently announced Solidoodle. There’s almost sixteen times difference from the bottom to the top of the range. But, you say, these 3D printers are priced differently and therefore there’s more to the story. We agree and thus we did an additional analysis to determine the cost per build envelope cubic centimetre. The results are interesting (click for larger view, results in USD$ per cc of build volume):

The cost per cc of build envelope also ranges by a factor of seventeenish. The least expensive by quite a margin is the open source RepRap, which is not surprising as it is non-commercial, uses common parts and you build it yourself. The most expensive turns out to be MakerBot’s assembled Thing-O-Matic. As a rule, kits are less expensive than their corresponding assembled versions. The most expensive device, the BFB 3D Touch isn’t the most expensive per cc as it benefits from economies of scale.

But we think build envelope per dollar is not a terribly useful decision metric for several reasons:

- Few people actually attempt giant builds due to a higher probability of failure, the massive amount of plastic required and the eons necessary to complete the print

- Machines have other differentiating characteristics such as number of extruders, heated platforms, reliability, maintainability, quality of output, maximum resolution, etc.

- Manufacturers differ in the amount, type and quality of support offered

- Large 3D models can be broken up, printed in smaller parts and then assembled

In other words, just ignore the analysis above and make your purchase decision based on all relevant factors. Size doesn’t count so much.

[UPDATE] Added the Up! 3D Printer to the charts.