One of the benefits of attending an event like Rapid 2012 is the ability to see, touch and literally get inside the latest 3D printing equipment. At this year’s show we were able to examine Stratasys’s most recent announcement, the sub-USD$10K Mojo 3D printer, for which we wrote a detailed analysis when it was announced earlier.

The Mojo build chamber. It’s a bit smaller than its sibling, the uPrint, but still able to accommodate eighty percent of the prints made on the larger machine. How large is it? It’s five by five by five inches – yes, large enough for many prints.

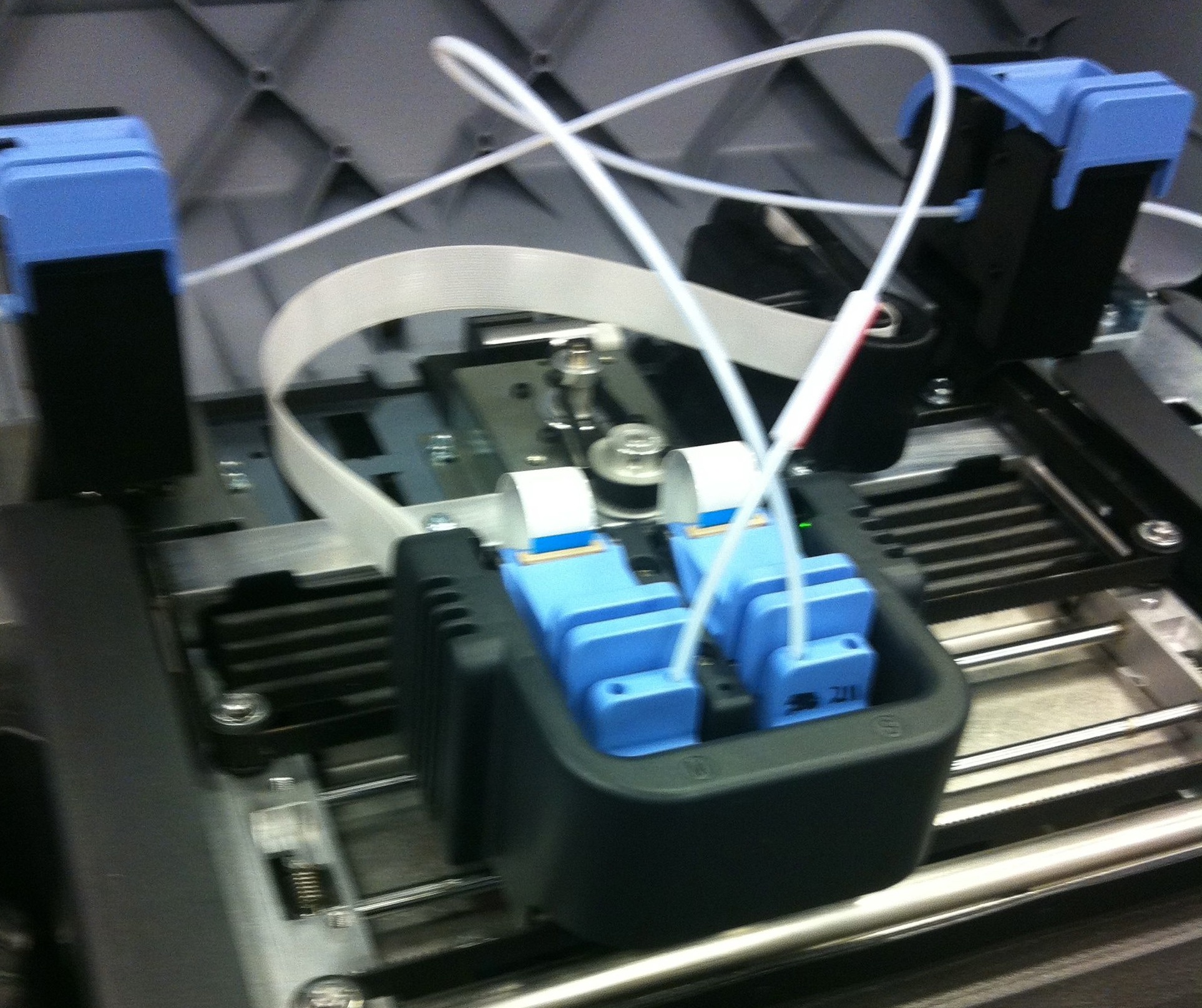

The Mojo build chamber. It’s a bit smaller than its sibling, the uPrint, but still able to accommodate eighty percent of the prints made on the larger machine. How large is it? It’s five by five by five inches – yes, large enough for many prints.  Detail of the Mojo’s revolutionary “Print Engine”. The ABSPlus plastic filament has an extruder motor always attached to the end of the filament. You need only drop this into the heating element at the top of the Mojo here (in blue). Also notice the accordion-style roof of the heated chamber that allows the print engines to move around the chamber.

Detail of the Mojo’s revolutionary “Print Engine”. The ABSPlus plastic filament has an extruder motor always attached to the end of the filament. You need only drop this into the heating element at the top of the Mojo here (in blue). Also notice the accordion-style roof of the heated chamber that allows the print engines to move around the chamber.