There’s a new 3D model pattern slowly emerging within the 3D print community that should lead to much more interesting printable objects.

In the early years, 3D printers were not particularly reliable or capable. In fact, they still could be considered so, but they have improved somewhat in the past year as manufacturers tune their hardware, constrain the plastic chemistry and calibrate their software accordingly.

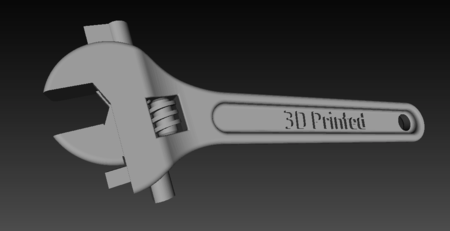

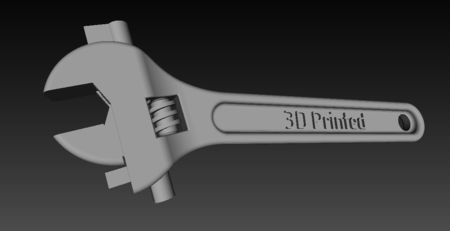

But what does this improved reliability mean? We think it should enable printing more complex objects, such as the wrench above. But first, we’d like to remind of the story behind the wrench.

In 2011 a piece on the National Geographic TV network apparently showed a fully-functional wrench being scanned and then printed. This is obviously impossible, as a 3D scanner cannot identify moving parts within a mechanism, even one as simple as a wrench. It turned out the show had effectively “faked” the operation as they “skipped” the part where the 3D model was actually constructed.

Back to today. Thingiverse creator Daniel Noree of Sweden recalled the wrench incident and decided to see whether a wrench could actually be 3D printed. He designed a wrench with movable internal parts, just like a real wrench. This was done by simply leaving small gaps (0.55m) between the parts to permit movement. This means the wrench is 3D printed in a single operation – no printing and assembling of separately printed parts required.

However, in order to 3D print such an item, support material is required, as the “gapped” parts simply can’t float in mid-air. By removing the support material the parts actually moved!

Normally this is most easily done on a high-end powder-based 3D printer, but now we see this approach successfully used on personal 3D printers.

We must say, however, printing items like the wrench with small gaps separating isolated parts is very challenging and could require many attempts and fine tuning of your 3D printer.

But if you can manage it, you open up a new world of printable possibilities.

Via Thingiverse