If you have a plastic extrusion-based personal 3D printer, there’s some things you’d better know. This printing technology has its quirks regardless of the brand and model of machine you’re using. We’ve put together a few of the most basic things to know before you get started.

Level The Bed: Perhaps the single most important thing you can do to encourage successful 3D prints is to make certain your print bed is as level as humanly possible. Even a slight tilt can cause your 3D printer to have varying gaps between the print nozzle and the bed. This means in some areas the nozzle might be too far from the bed resulting in bad sticking; in other areas the nozzle will be too close resulting in extruder jams. Follow your manufacturer’s instructions – to the letter!

Set The Z-Gap: If your bed is level, you then must make certain your Z-Gap is properly set. It’s the space between the print head and the bed. If the gap is too low or zero, there’s little space for molten plastic to come out of the nozzle. If it’s too high plastic might not be able to properly stick to the bed. Again, follow your manufacturer’s instructions.

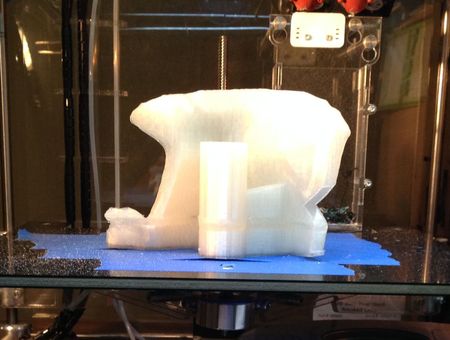

Watch The First Layers: The most important part of any 3D print is the first layer. It must successfully adhere to the print bed otherwise you’re going to have a lot of trouble as the print proceeds. Therefore it’s good practice to carefully observe the first few layers as they are deposited. If they succeed, it’s likely the remainder of the print will work. If not, it’s advisable to cancel the print and try again – you’ll save time and a lot of plastic filament.

Print Small: Resist the urge to print gigantic items. The larger your print, the more likely something will go wrong. Smaller prints take much less time to complete and you will be a happier 3D printer owner. Try larger prints when you have experience and are willing to withstand some disappointment.

Maintain Your Machine: Your 3D printer is a very mechanical device. It has moving parts that require maintenance. Follow your manufacturers maintenance instructions closely. You will likely be cleaning and lubricating moving parts. Also ensure you keep the machine clear of dust and debris: these can easily contaminate your filament feed system and gum up your extruder.

Be Patient: Printing takes a long time; impatience will lead to huge disappointment. Printing also fails frequently. Plan for failure and be happy when things work.