As you become accustomed to making objects on your personal 3D printer, you’ll soon learn there are several pathological geometric shapes you will hate.

At first many 3D printer owners mistakenly believe their machine can “print anything”, but of course that’s not the case. Some shapes are definitely easier to print than others.

The first problematic geometry usually discovered is “overhangs”, where part of the object has no material underneath for support. If a cantilevered shape exceeds, say, 45 degrees or so, you may experience slumping or outright failure. Overhangs can be almost completely solved by using supports in your slicing program, but you’ll have to spend time to remove them. Depending on the slicing software, removal could be easy or exceedingly tedious.

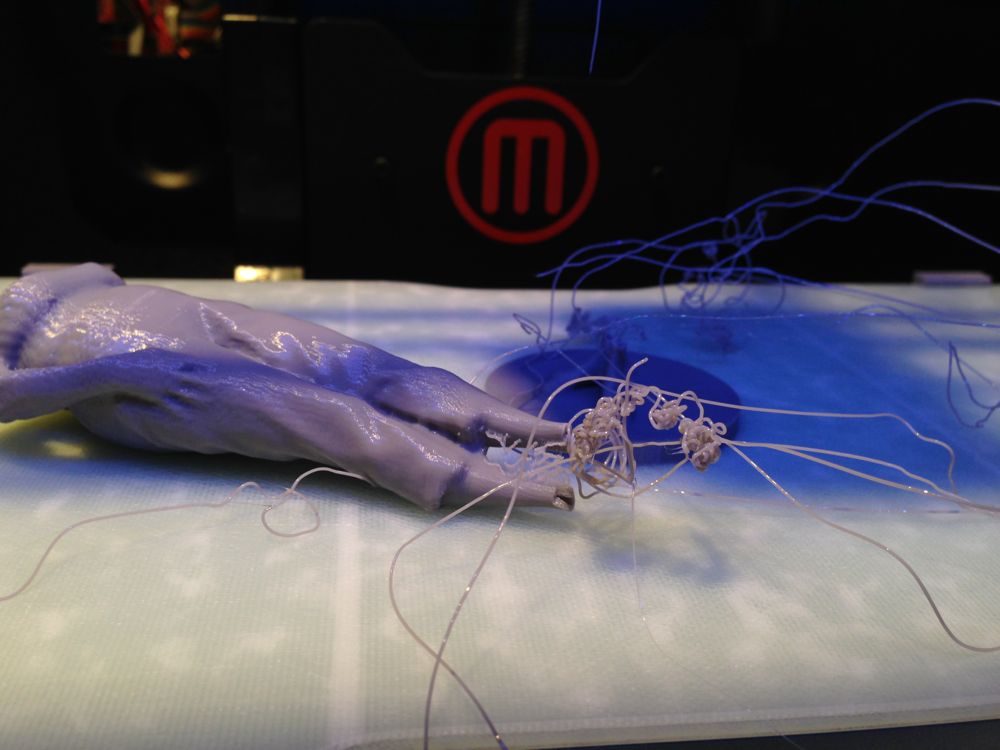

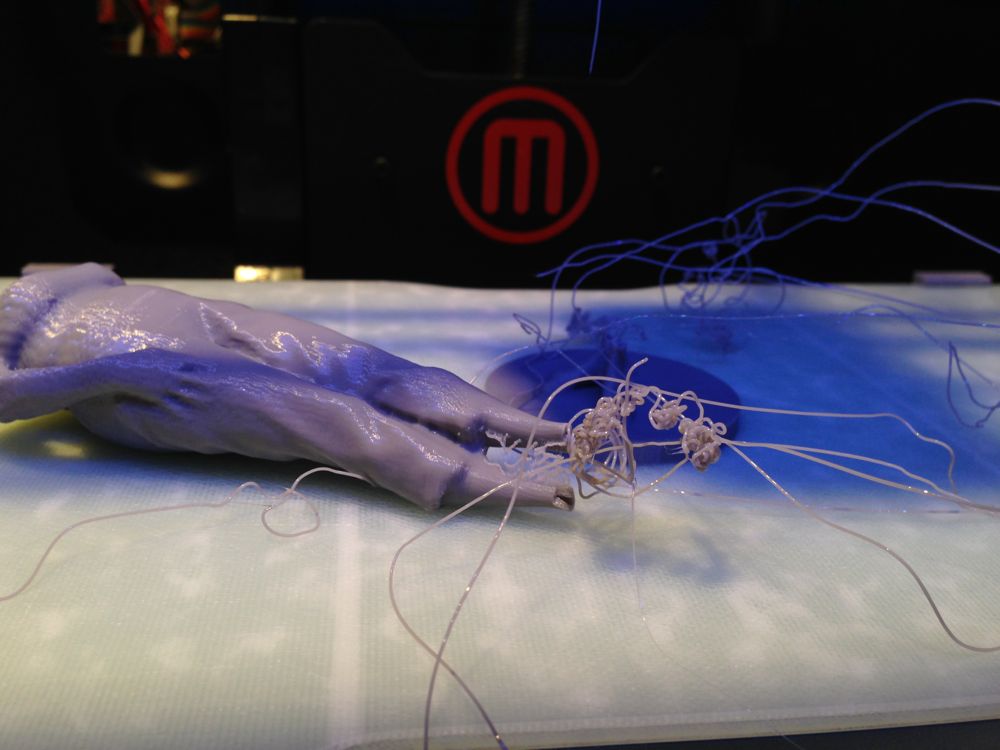

Another problematic geometry is “thin structure”, as shown in the image above. Typically a large mass is to be supported by very small structures. Such non-robust shapes can permit wobble during printing that can sometimes lead to cracking and total failure, also evidenced above. The solution is to simply design your object to have sufficient “leg strength”. However, in cases like the above image, this can’t easily be done because it’s a 3D scan of a person. Can’t make their legs fatter without asking for trouble! Instead consider adding a temporary support to the model and removing it after printing.

Long, thin elements at the base level can also cause issues. Why? Because warping tends to occur along lengthy axes; the small amount of shrinkage is amplified over a long component, particularly if the extrusion path matches the axis and most particularly if you print in ABS plastic. This can be resolved by using a heated print plate, but if you don’t have one, you’d best stick to printing circular bases in PLA.