A new 3D printer is capable of printing silicone objects.

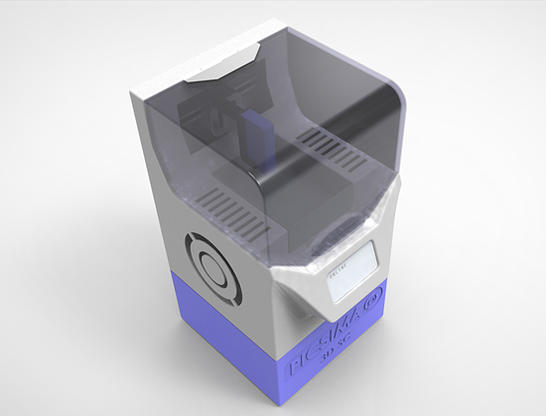

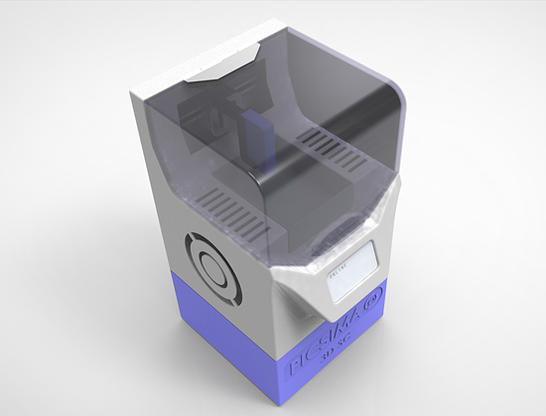

The machine is the Picsima, made by Fripp Designs of the UK. If you watch the video below, you’ll see their machine is very capable of printing highly useful silicone parts able to stretch to great lengths without snapping.

It’s not entirely clear which 3D printing process is used by the Picsima. The company says they’re using standard, off-the-shelf silicone resins, so it’s unclear they’re using a photo-curable technique. Regardless of what it is, they’ve applied for patents over a year ago, so they must believe it is unique.

And it seems so, given the results. They’re comparing their 3D printed silicone with Stratasys’ Tango Black+ flexible material. Tango Black is often used to print gaskets and other flexible items, but it’s clear that Picsima’s silicone has another dimension of flexibility and stretchability. They can produce objects with flexibility down to Shore Hardness 10 A, which is more than Stratasys can do, at least with their current materials.

Another key difference from Stratasys’ solution is material cost. Evidently the Picsima uses standard silicones that carry commodity pricing, unlike Stratasys’ proprietary Tango Black.

Even better, these standard silicones have already received regulatory approval for medical use.

Currently the Picsima can print silicone objects as large as 100 x 100 x 30mm, which should cover a wide range of gaskety-style objects. Resolution is not terrific, however, being only 0.4mm. However, that might be more than sufficient for the types of silicone objects coming out of this device.

We believe you can purchase a device, but it seems that Fripp is focusing on Picsima as a 3D print service. You can submit your designs for Gaskets/Seals, Prostheses, Smart Devices, Medical or Soft Tooling and they’ll produce the objects on their fleet of Picsimas in less than two days.

It also appears that Picsima will eventually use other polymers aside from silicone, suggesting this machine could be quite versatile.

We don’t know the size and strength of this company, but it is not unreasonable to suspect they have serious backers if the technology is as unique as suggested. However, they seem to be positioning to compete directly against industry giant Stratasys, who, in theory, could punch out a new material that has similar properties. The future will be interesting.

Via http://www.picsima.com/