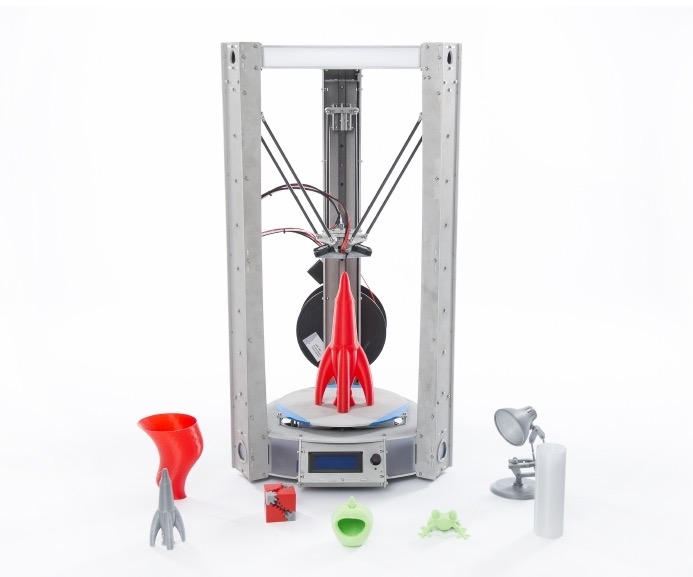

Looking for a large-volume personal 3D printer? You might want to consider the Belgian-built deltaRocket.

It, as you might suspect, uses the delta approach. While many 3D printers use the “cartesian” approach, in which the print head moves along three axes (X, Y and Z), the delta approach is quite different. deltaRocket explains this well:

A delta robot is a parallel arm robot, which consists of multiple kinematic chains connecting the base with the end-effector. The use of parallelograms restrict the movement of the end-effector to pure translation, i.e. only movement in the X, Y or Z direction without rotation. When this technique is used in 3d printing the printing head can move at high speeds, because of the minimal interia which is introduced in the system. The stepper motors which drive the carriages can remain stationary, so the moving mass can be held at a minimum.

In other words, you can build a high-speed, high-accuracy, high-volume 3D printer at a reasonable cost. But what about deltaRocket’s implementation?

Their design is similar to other deltas, offering a generous build volume of 220mm diameter by 300mm tall (delta printers measure build volume in cylindrical shapes, not cubic). The machine prints as small as 0.1mm layers, which is more than sufficient for the larger prints that will emerge from this machine.

The deltaRocket apparently can print both PLA and ABS, since it includes a heated glass print surface.

Sold as a DIY kit, the deltaRocket is available for €1,575 (USD$1,920).

Via deltaRocket