We took a closer look at Nanoscribe’s nano-scale 3D printing technology to understand how it works.

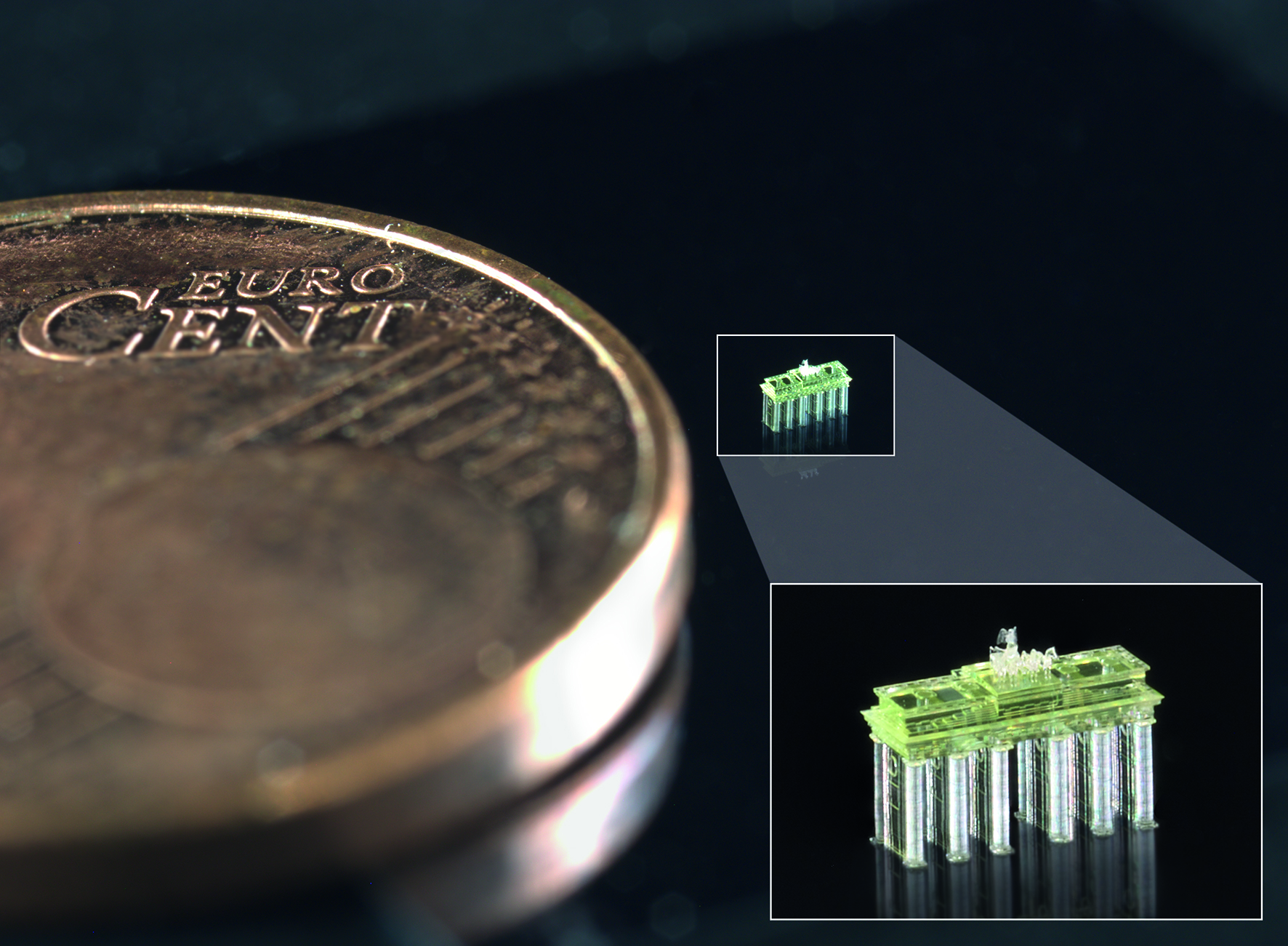

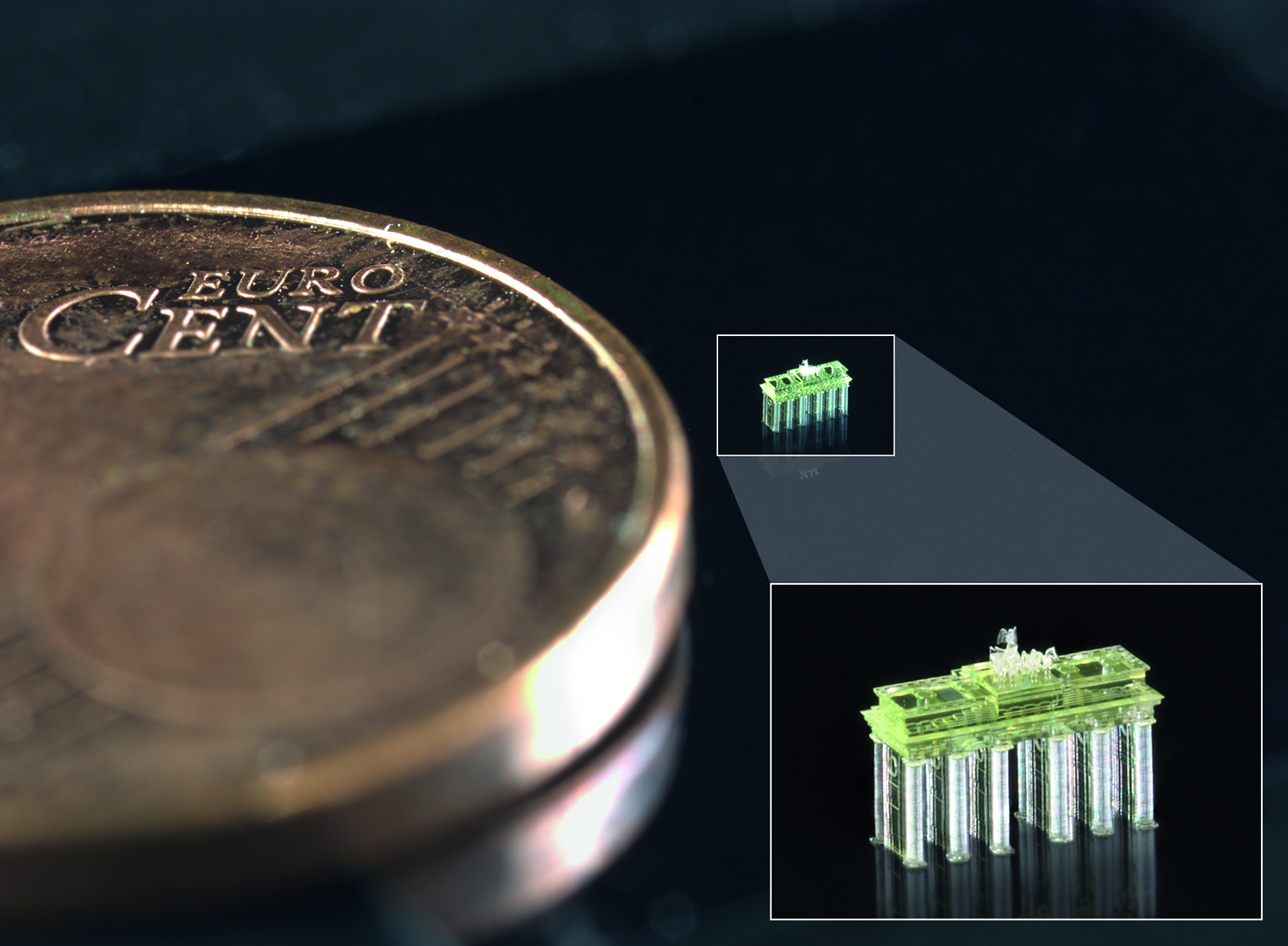

Their process is capable of incredibly small 3D prints, as shown in the story of the world’s teeniest human 3D print, where the print was so small it was almost lost. But how, exactly does this process work?

The process is remarkably similar to “large scale” 3D printers, in that it also uses photo-curable resins. This is typically done by DLP light engines or moving laser beams in more conventional equipment. In Nanoscribe’s case, they employ a laser.

The size of the laser beam actually determines the final object resolution, so if it can be made smaller, then the resolution improves. That’s precisely what Nanoscribe does: they say:

By using focusing optics with a high numerical aperture, very small voxels with sub-micrometer dimensions can be achieved.

In other words, they’ve shrunk the size of the laser to microscopic proportions with high-end optics. But how do they move the laser? They’ve tried two different approaches. First, they move the object very slightly with “high-precision positioning” equipment, but they found this “fixed beam” approach is slow compared to the alternative approach.

The second method is to use a moving laser beam that progressively sweeps across the photo-curable resin surface. Their equipment uses a combination of galvanometric mirrors to move the laser beam and piezo-actuators to raise and lower the resin surface. This approach proved much faster than the fixed beam method.

The technology they’ve developed is astonishing; we know of no other method of 3D printing such tiny objects. While they’ve used the tech to produce notable artworks, such as the almost-too-hard-to-see Brandenburg Gate in commemoration of the 25th anniversary of the fall of the Berlin Wall, it remains to be seen how the technology can be applied for industry.

At this point Nanascribe appears to be positioning the technology for research purposes. In other words, researchers requiring very small parts or structures can now obtain them. This may include very small mechanical devices, scaffolding, plumbing, optical or other functions. These researchers will no doubt eventually discover practical applications of nanoscale 3D printing.

Via Nanoscribe