Remember the 3D printer sent to the International Space Station? The first prints from it have been examined by NASA.

The orbital 3D printer, produced by California-based Made In Space, was used to print a series of carefully designed test objects in the past few months. These objects were bagged, tagged and dropped back to Earth on the most recent SpaceX Dragon resupply mission. The Dragon carried supplies and consumables to the station and on the journey home brought experimental samples, including the precious first 3D prints from space.

In the video here you’ll see Quincy Bean, the principal investigator for the space station printer, open up the box and examine the 3D prints for the first time.

He explains what happens next, which is not surprising as this is a scientific experiment. They want to verify whether the prints were comparable to what is produced on the ground. To do so, they will take a number of high-resolution images of the items and compare them to images taken of “control” prints previously made on the ground. They’ll also use a 3D scanner to capture the external shape and dimensions of the prints to again compare them to what’s expected from the original 3D model as well as control prints.

They’re looking for evidence that the 3D printing process works correctly in microgravity, with two specific things in mind: layer adhesion and supportability.

In a typical filament 3D printer on the ground, extruded filament is pushed and falls a bit due to gravity onto the print surface. In microgravity, the 3D printer must rely entirely on the force provided by the extruder. Does this work properly? Examinations will tell us.

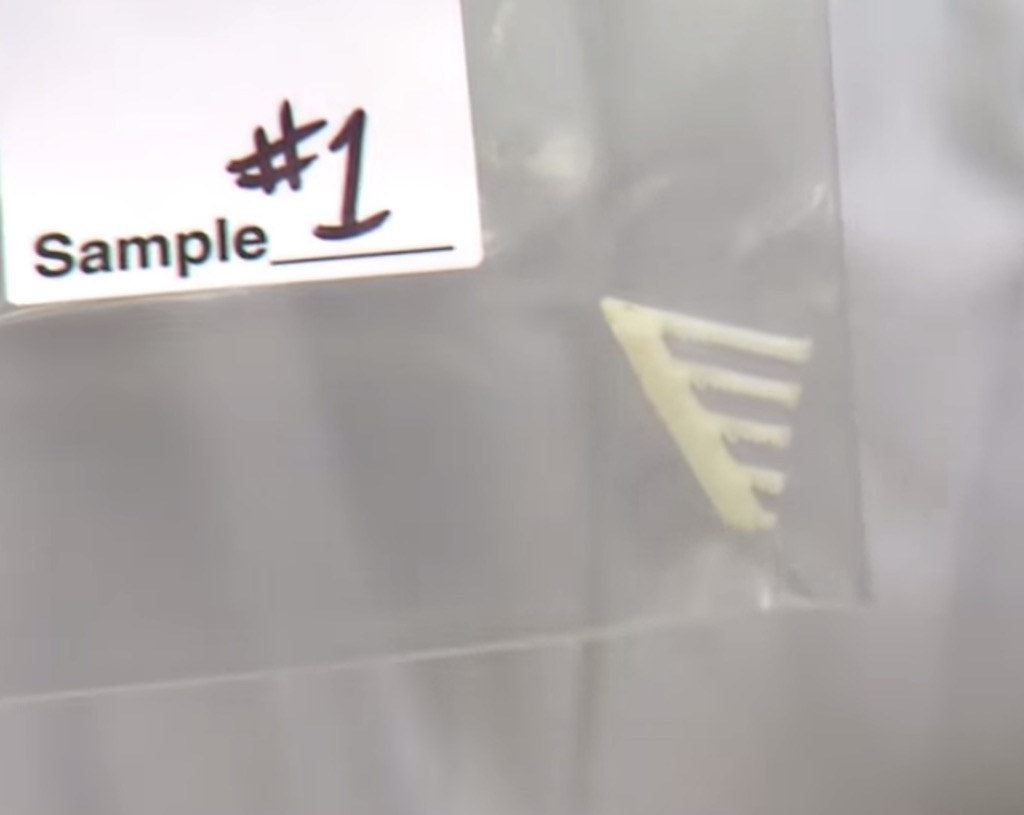

The other very interesting factor is supportability. On the ground, filament-based 3D printers must be cognizant of cantilevered structures. If they are too extreme, gravity will pull them down to form a slumped structure. Ground-based 3D printers require support structures to deal with the annoying effects of gravity. However, this is not the case when in orbit: no gravity will pull down cantilevered features. One of the test models (shown here) tests this effect by printing very extreme cantilevers. Surprisingly, they seem to have worked very well!

Evidently you’ll be able to 3D print in space without the need for support structures.

What’s next? Bean points out that the 3D printer is still installed on the space station and can be used to print further items. The plan for “Phase 2” is to print more practical items based on the findings from Phase 1. These will be item astronauts might actually use in their daily jobs.

We suspect the next Dragon flight might include a few kilos of 3D printer filament.

Via NASA