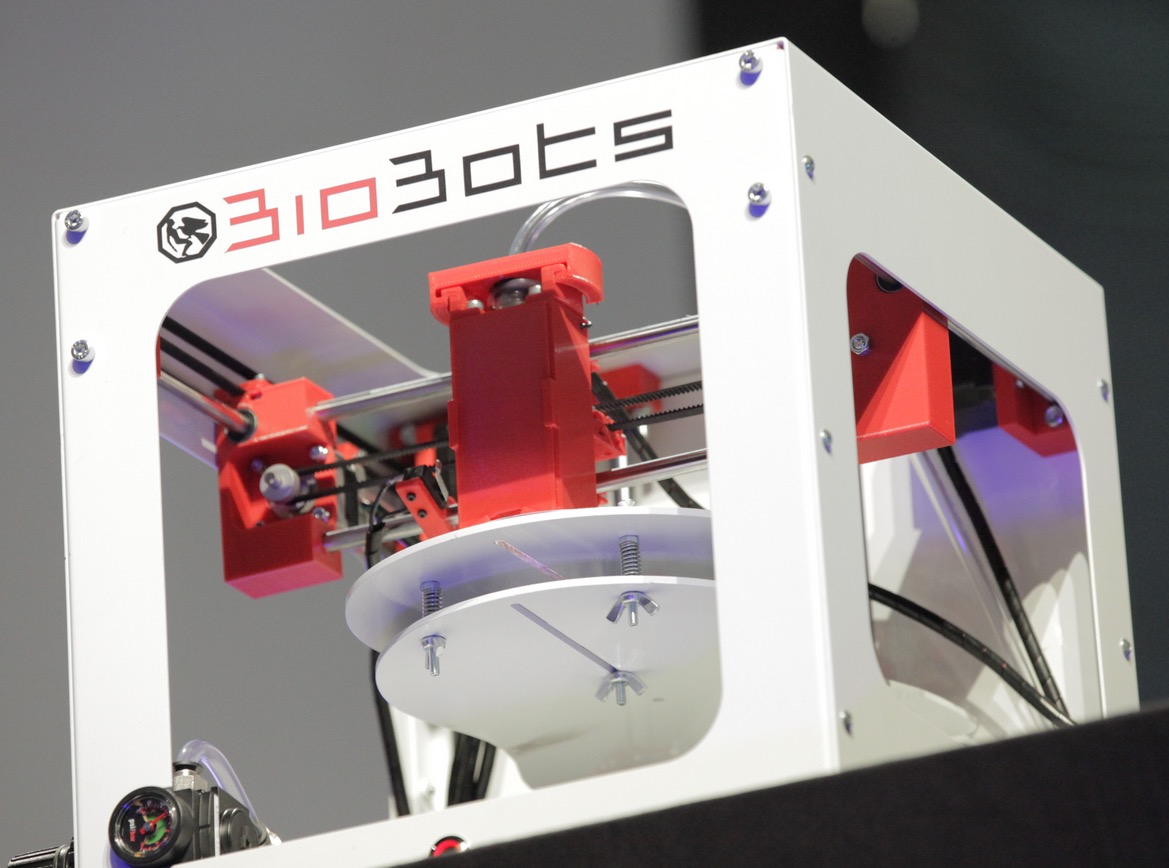

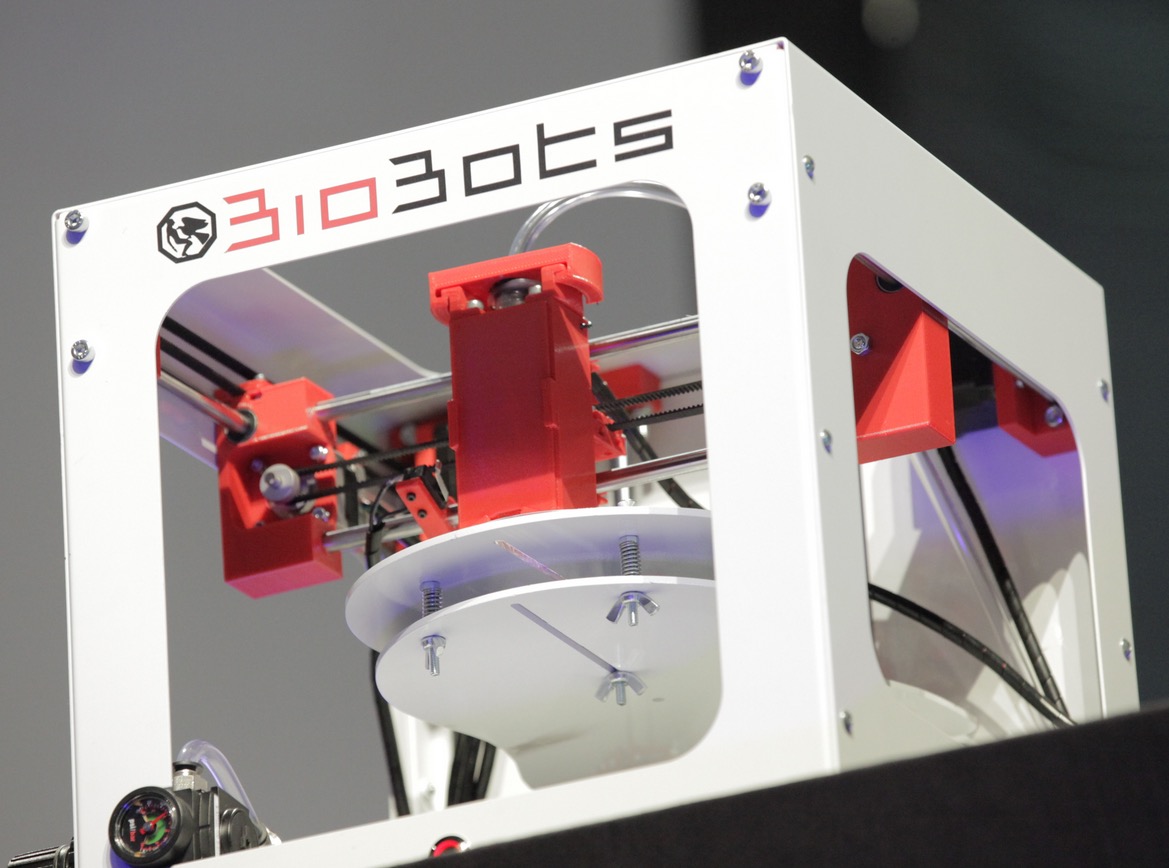

A startup has developed a functional bioprinter they’re preparing for sale.

BioBots’ tagline is straightforward, but powerful:

Low cost, high resolution, 3D bioprinters revolutionizing the field of regenerative medicine.

The science of bioprinting is vastly more complex than 3D printing inanimate plastic materials, simply because the material is alive – and must be kept alive before, during and after printing. Typical bioprinting processes involve depositing a bio-friendly lattice structure upon which are deposited the living cells of interest. These cells grow and the lattice dissolves, leaving a fully bio-engineered tissue section.

The BioBots machine includes a 90 x 90 x 90mm build volume, which may seem quite small by 3D printing standards, but it is more than adequate for many bioprinting applications. Layer size is 0.1mm, suitable for producing delicate lattices for cell deposition.

While the machine is made robustly with a stainless steel frame, it’s not likely you require as much strength: bioprinting can be slow, depending on the nature of the biological material being produced.

They say they support “dozens of materials” and use “blue light technology” to cure printed lattices without harming living cells. This suggests the machine uses a resin-based process, yet their specifications say they use “Fused Deposition Manufacturing”, similar to Stratasys’ “FDM” trademark for plastic filament extrusion. It turns out the machine simply extrudes a liquid containing a mix of living cells and powder, one of which is a binder that solidifies when exposed to the blue light. Normally, this type of 3D printing uses an ultraviolet light, which would kill any living cells, so they’ve overcome that challenge.

The machine leverages open source 3D printing software, but apparently the company has added some customizations to GCODE for their machine.

Bioprinting, like conventional 3D printing, requires careful tuning of extrusion parameters such as print speed, nozzle size and more, but the specifics are quite different. BioBots explains some of the factors involved in determining material compatibility:

- <100 Pa·S, which is too watery to hold the printed shape

- >104 Pa·S are too viscous and difficult to be deposited smoothly

- Parameters for Resolution and Viability

- Nozzle Diameter

- Pressure on Material

- Printspeed

It’s likely the company will provide advice on tuning your prints.

Currently the machine is not yet available, but it is priced at USD$25,000, less than some other commercial bioprinting solutions. If the company succeeds, this could put bioprinting capability into many more hands.

Via TechCrunch and BioBots