As the technology of 3D printing increases in capability and reliability, where does one’s workload land? We think it’s in the design.

3D printing is actually a two-part process. While printing produces the final object, that can only take place once a viable 3D design has been created. 3D printing cannot occur without a design.

And that printing is done in a manner quite different from historical methods of making, where a skilled craftsman used hand tools to carefully prepare a practical or beautiful object. Today, barring print disasters, you need only push the start button to “make” your object.

So where is the work in obtaining an object? It’s in the design, obviously. Whereas in the past, the production of a given object involved a great deal of time spent physically making the item, far less time was spent designing it.

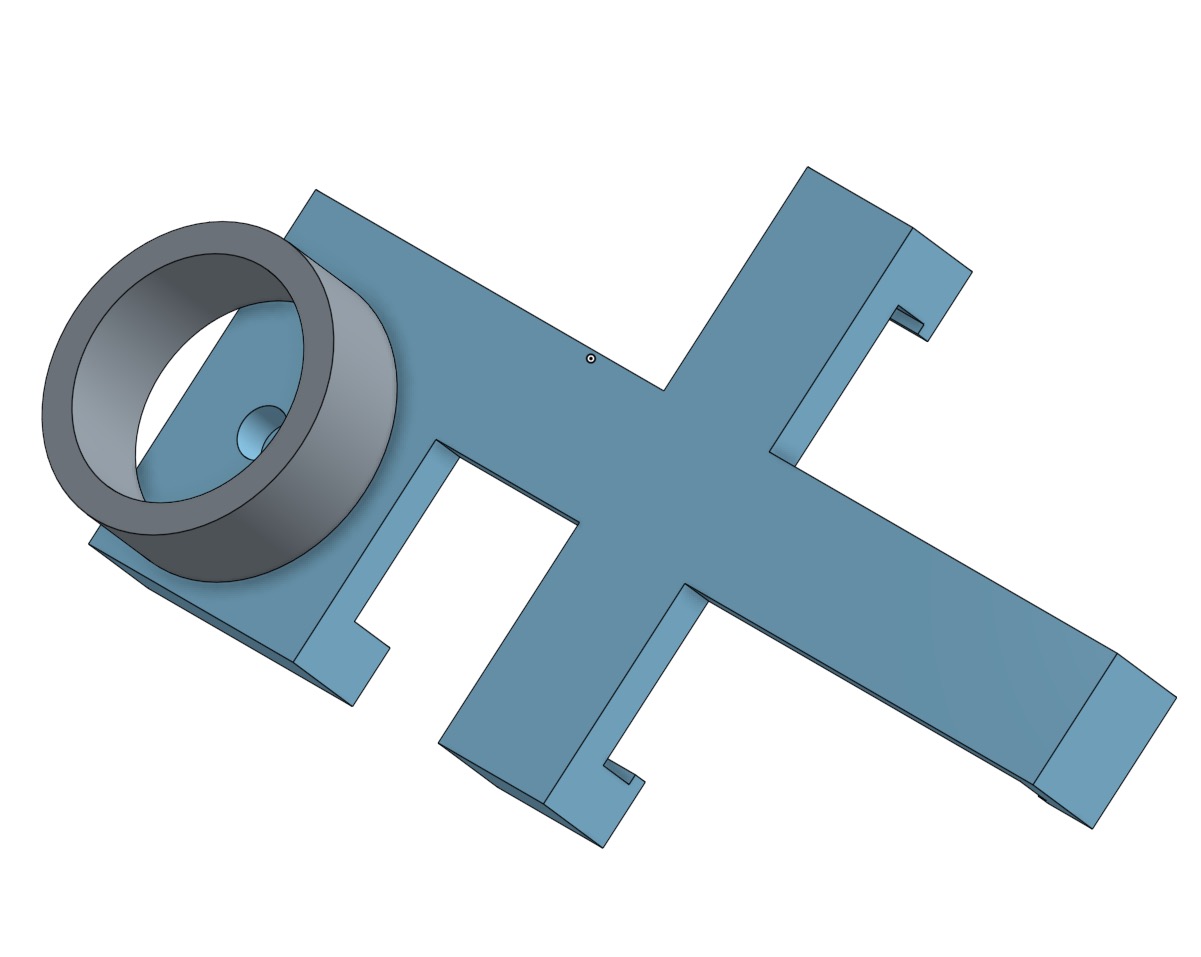

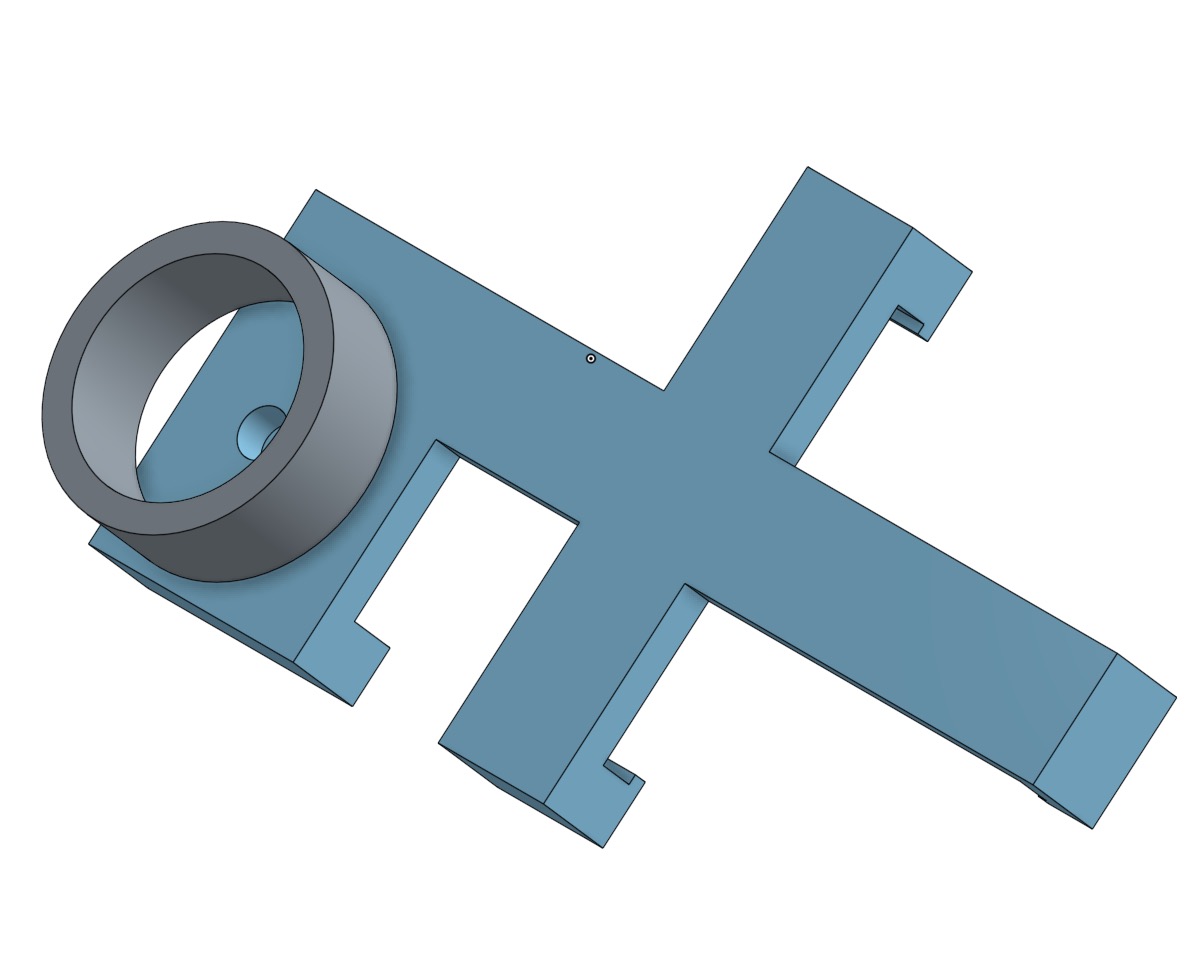

Now that’s changed, specifically with the advent of modern making machines, such as 3D printing. By far the bulk of the time to produce an object is now in the design phase – or at least the conscious labor time; some 3D prints, while automated, can still take days to complete. The point here is that most of the human effort is now in preparing the design using 3D CAD tools.

Of course, this effort can be short-circuited by using a previously designed 3D model, many of which can be obtained from various 3D model repositories and model generators. But even so, someone did spend considerable time to develop that useful pre-made 3D model for you. Time-wise, there is no shortcut.

And this is perhaps where the ultimate barrier to widespread use of 3D printing may be: many people are simply not able to dedicate the time and obtain the expertise to execute the design phase. It may be that 3D printing remains the realm of industry and the relatively few in the public able to perform 3D design.

Two things could change to tip this equation over:

A vastly simpler method of CAD could be developed. Currently CAD tools, while very capable, are tremendously difficult for many to learn – and purchase. There have been a number of different attempts at doing so, but none have yet succeeded in becoming the truly “easy” way of designing 3D objects by anyone.

A second approach would be to create an array of object generators, which could, with simple inputs, generate the required 3D models. Imagine, for example, a mechanical bolt generator: there are a known number of parameters for a bolt, such as diameter, thread size, etc, which could be specified and an appropriate 3D model created. We would require only one generator for all types of bolts. With more generators of that type, we could gradually cover off at least the common objects. But this doesn’t address the requirements of assembling complex machines composed of many parts.

We await 3D model creation developments.