A new microscopic 3D printing process has been developed by Swiss company Cytosurge, and it can print metal!

The new process is called “FluidFM” and leverages previously developed microscopic mechanisms. Specifically, FluidFM makes use of “hollow atomic force microscopy cantilevers”.

What the heck are those? They are tiny structures used to deposit extremely small amounts of liquid, typically used in chemical or biological experiments.

Here’s the magic part: the FluidFM process uses them to perform a type of selective microscopic electroplating. This is how they describe the process:

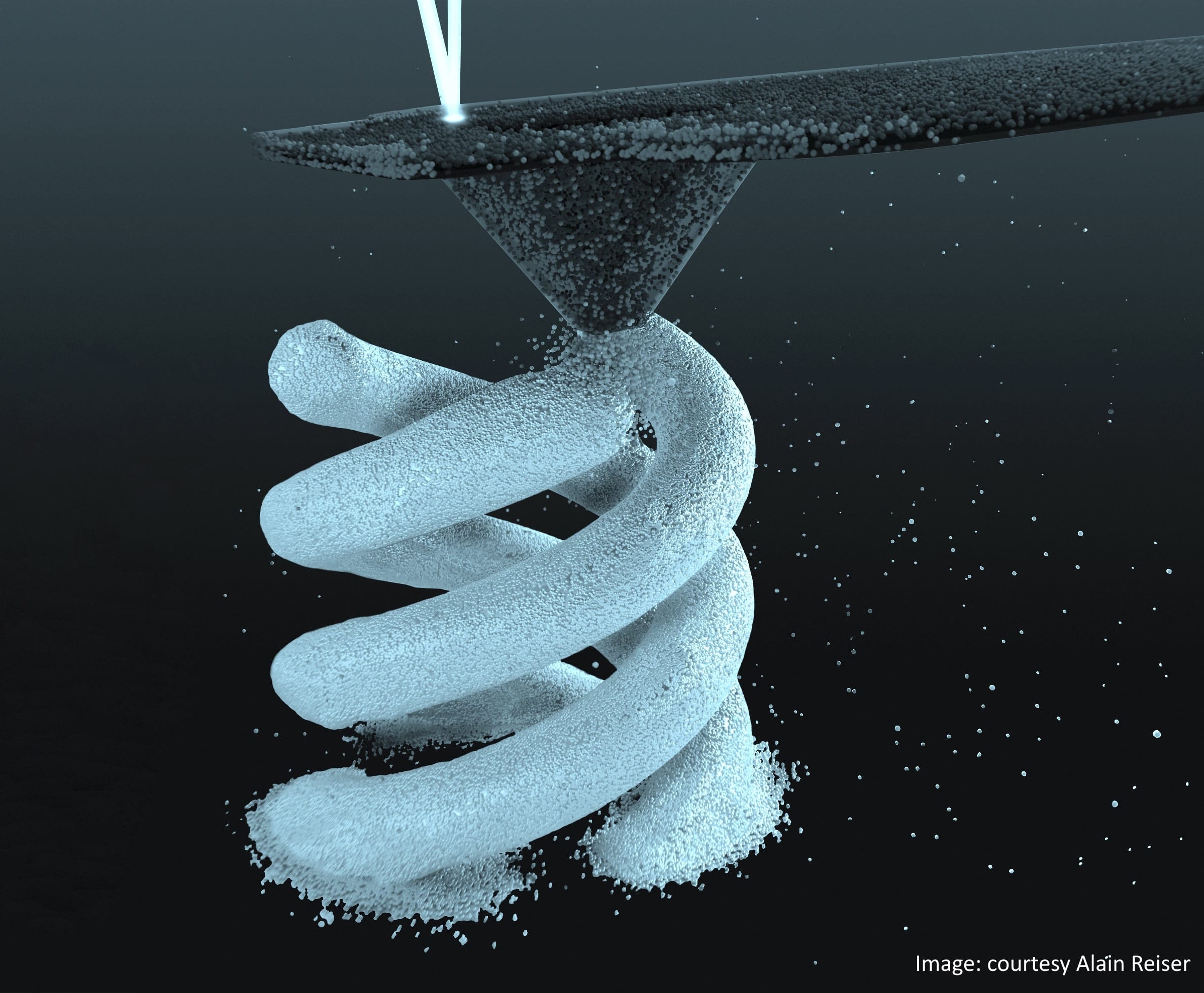

Hollow atomic force microscopy (AFM) cantilevers are used to locally supply metal ions in an electrochemical cell, enabling a localized electroplating reaction. By exploiting the deflection feedback of these probes, electrochemical 3D metal printing is, for the first time, demonstrated in a layer-by-layer fashion, enabling the fabrication of arbitrary-shaped geometries.

You can glimpse how it works in the image at top.

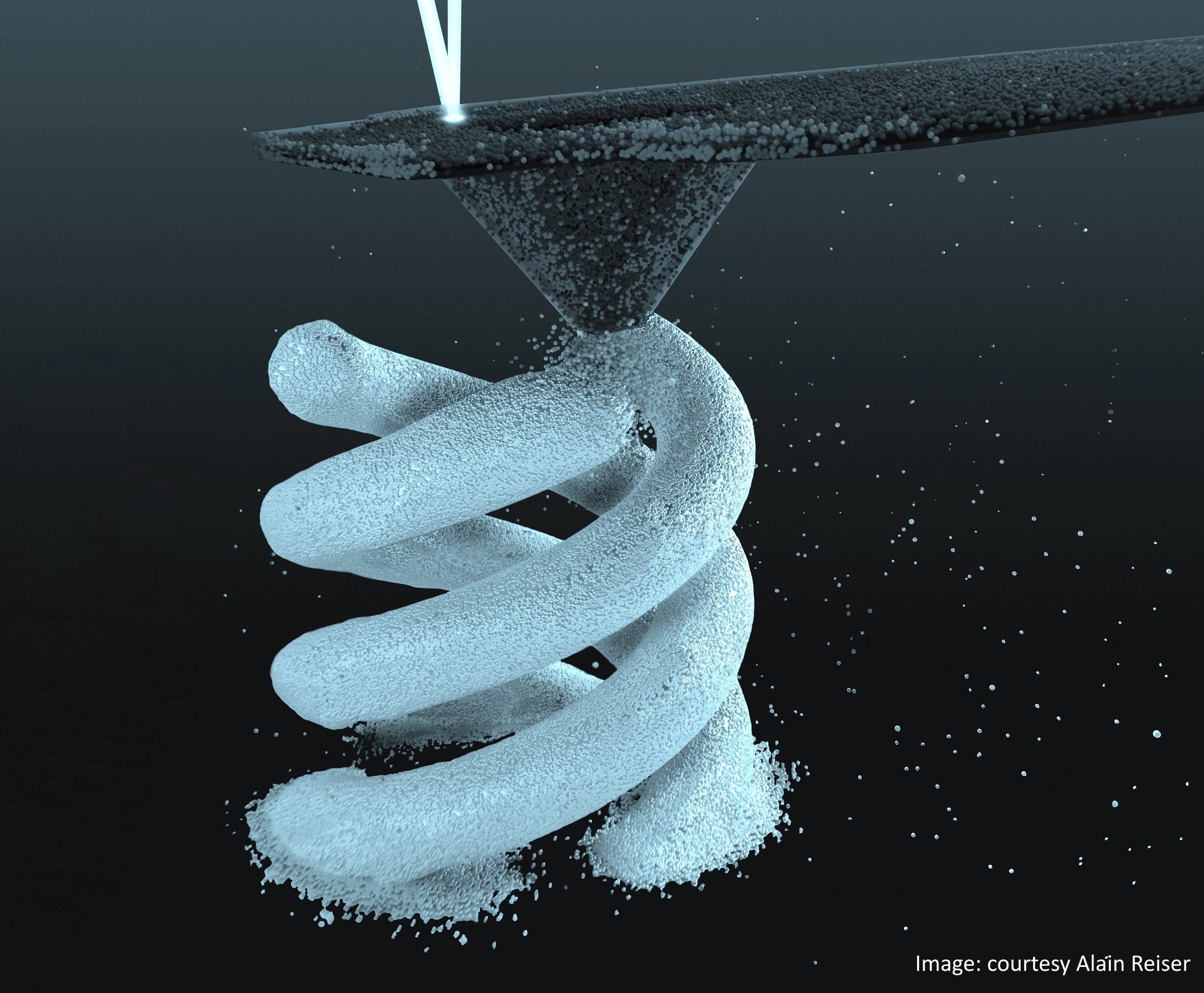

Using this process, Cytosurge has been able to 3D print some very interesting objects at extremely small scales, like this coil.

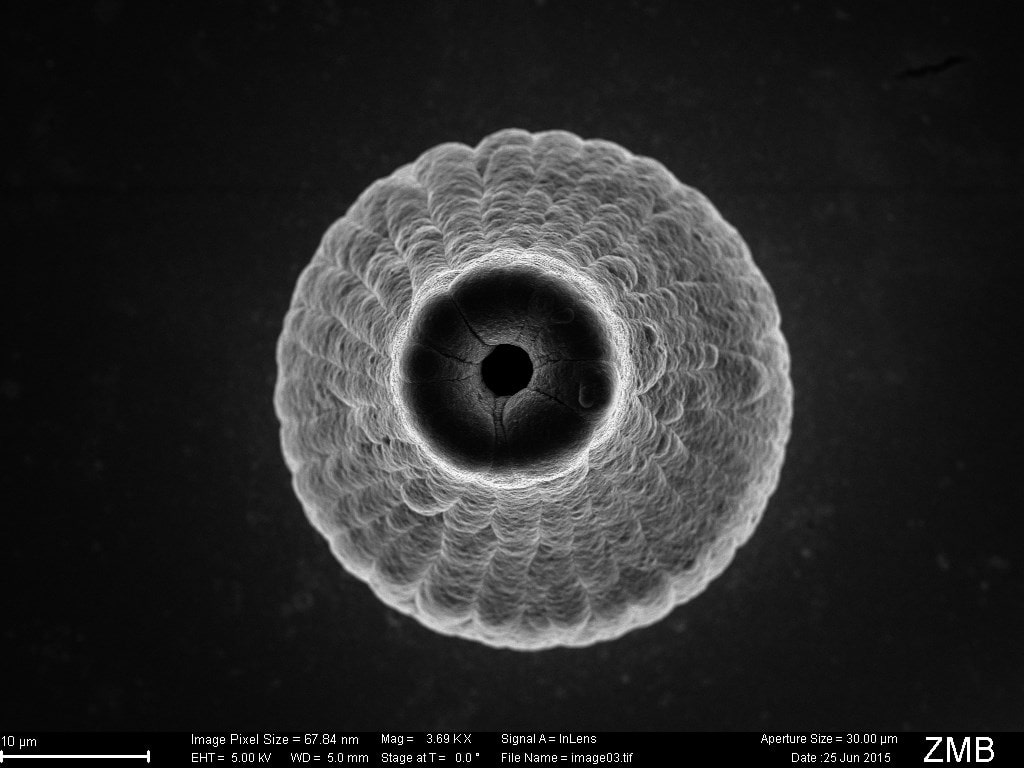

Or this, this, whatever it is. In any case, you can see that relatively complex shapes can be produced – in metals.

We’re not certain which metals are suitable for this process, as FluidFM may be restricted to metals that can be electroplated.

There certainly may be a market for nano-scale complex metal objects, particularly as nano-machinery experiments continue. In fact, this process may even enable more advanced nanotechnology.

Other metal 3D printing processes produce objects at far grander scale, but we’re wondering whether this process could be scaled up in the same way inkjet technology can be used to create large prints by using arrays of individual inkjet mechanisms. Could it be possible to 3D print larger metal objects with ridiculous resolution using this process?

The other observation we have here is that some may think 3D printing has stagnated, as all the useful processes have already been developed. That is certainly not the case, as this approach demonstrates very clearly. There are no doubt even more ingenious approaches yet to be invented.

Via Cytosurge