You’d think a manufacturer of liquid photo-polymer resins would know much about 3D printing with resins, and this company certainly does.

Photocentric is a 13-year old UK-based company that apparently is one of only five companies on this planet that manufacture liquid photo-polymer resins. They produce around 500 tonnes of such resins each year, much of which is resold by others, including 3D printer manufacturers in their proprietary cartridges. Currently they employ eight researchers dedicated to 3D print applications, with more researchers being added frequently.

The goal of Photocentric seems to be an increase in sales of resin, as their success depends on increased use of resin. They’re now taking some bold steps to do so: their big move is to market a pair of demonstration resin-based 3D printers that involve a very different use of resin technology.

Both units employ a unique approach to resin 3D printing that could prove very interesting for not only Photocentric, but also other makers of 3D printing gear, since the company intends on open-sourcing the approach.

Here’s how it works: a standard LCD panel is placed under the resin tank to shine pixels of plain light – and this is the important part – not UV, into the resin. The unmodified light source uses very low energy to solidify the resin.

But what of the sticking-to-the-bottom-of-the-tank problem that occurs in almost every other 3D printer that uses the bottom-up approach? Photocentric explained that their system’s very low energy is very different from others who use “far too much energy” when blasting UV at the resin. For them, this is what fuses the solidified resin to the tank. In Photocentric’s approach, they use very little energy so the resin solidifies without fusing to the PFA tank. Thus, these inexpensive resin 3D printers should operate very fast, similar to the Carbon3D method. They call the method “Daylight Polymer Printing”, or “DPP”. Yes, they have a patent pending on this approach.

There are other advantages to DPP as well. Since it employs only normal light, there is no danger to eyes as you might find in a laser-powered device. The LCD panel is so close to the tank that no focusing or optical elements are required. And it’s very inexpensive, too, as they’re using off-the-shelf components. The energy used is so low they say it cannot go beyond the cured area, implying good printing accuracy.

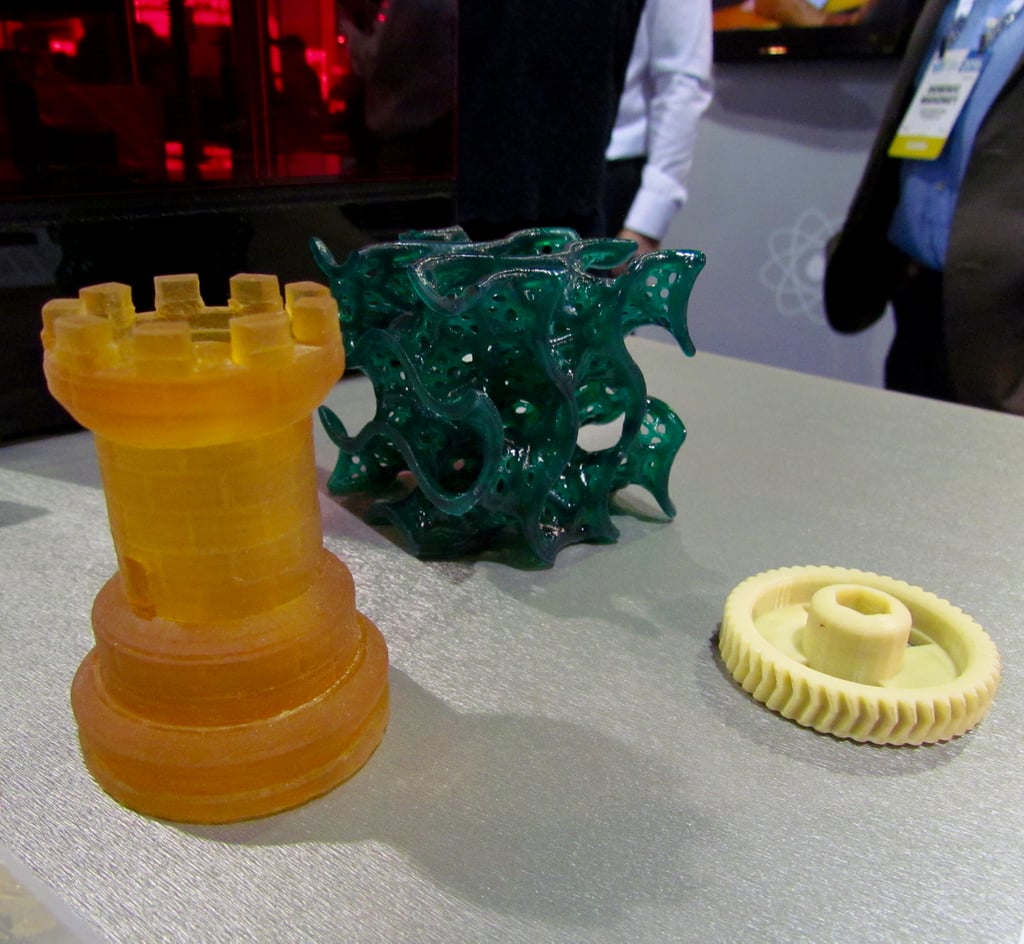

That seems to be the case, as you can see with the very good quality sample prints shown here.

The two “LiquidCrystal” 3D printers (The LiquidCrystal and LiquidCrystal Mini) differ only in build volume size, and are priced at the ridiculously low prices of USD$599 and USD$1,199. The printers are mechanically very simple and should prove quite reliable, and are available for pre-order now.

If you want to wait for three months, they say they may have a 17” (431 x 431mm) version available, no doubt using a standard 17” LCD panel to drive it. They’re even talking about a massive 40” version.

Via Photocentric