Readers of this blog are by definition interested in 3D printing, but there are other ways to manufacture objects. One of them worth considering is injection molding.

Injection molding is a long-proven manufacturing technology that likely produced many of the items around you right now. It typically involves the creation of a metal mold split in two halves. These are strapped together and hot, liquid plastic is “injected” into the space inside the mold pair. After a suitable amount of time to cool the plastic, the halves are split and a finely made object emerges. By polishing the surface of the mold, you can produce objects with mirror-like finishes.

But there are two main challenges with injection molding that usually prevent its use by DIY folks: first, the production of the metal molds can be terribly expensive, as they must be made with industrial CNC milling equipment. Often such molds cost tens of thousands of dollars to produce, but once made, they can easily produce thousands of units at low cost.

The second issue with injection molding is that the geometry of the object must be such that you can actually split the mold pair after cooling. If, for example, your object contained inner structures that would get “caught” on the mold, you’re done. For such “complex” structures, you will need to split the object into simpler parts for separate injection molding. This, guess what, costs even more to do.

But for those 3D printing enthusiasts that find themselves faced with printing dozens or even hundreds of identical items for a client, the lure of injection molding is strong: production speeds are substantially faster than 3D printing. If a 3D print took six hours to complete, it might be possible to produce it with an injection mold in only a few minutes.

Even if you’re in this situation, the cost of injection molding equipment usually puts the technology beyond reach.

However, there’s now a way you might be able to perform simple injection molding at a lower cost with a new device: the Many-Maker. It’s been launched on an Indiegogo campaign recently and is positioned as an accessory to a 3D printer.

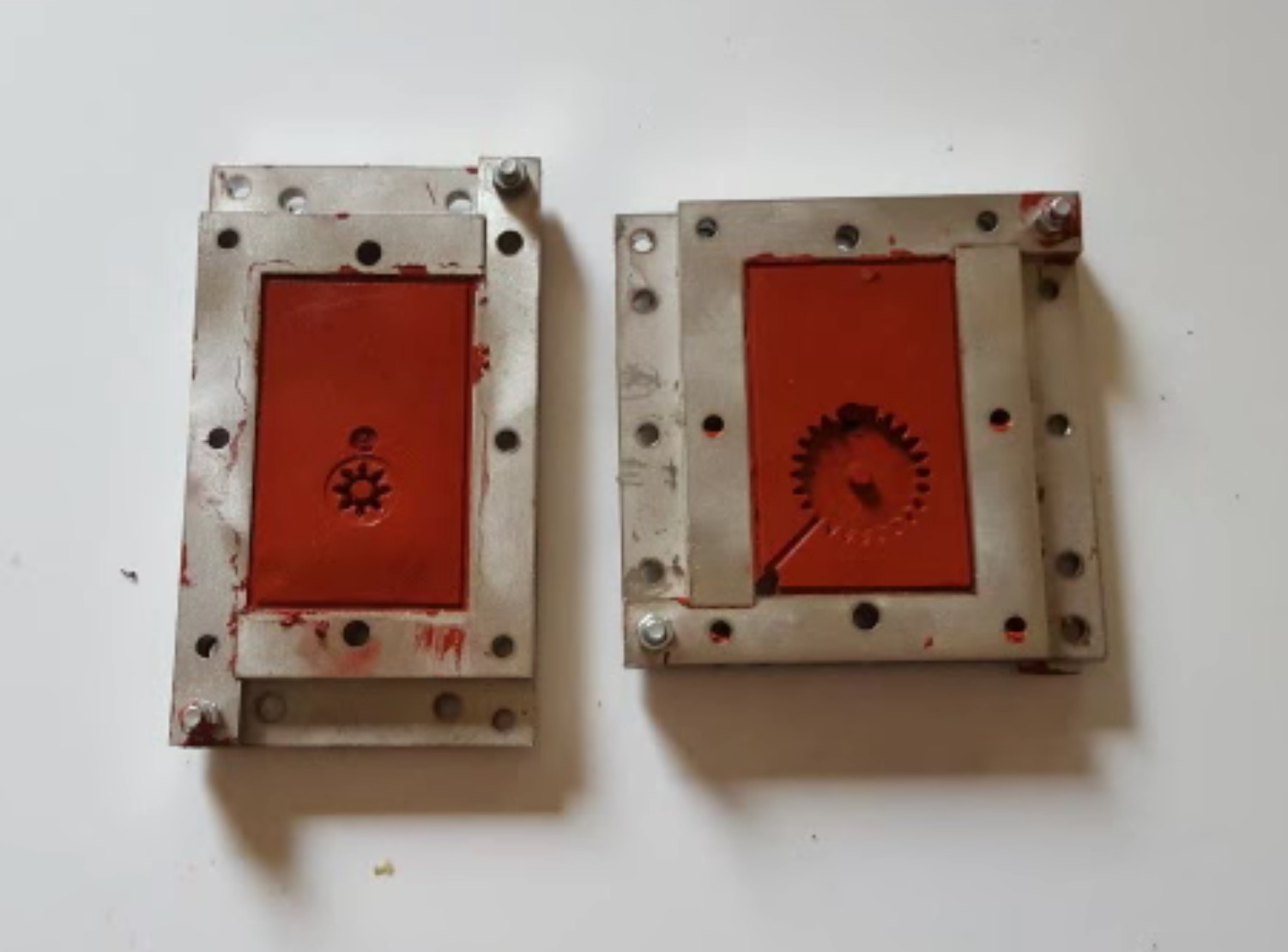

Here’s how it works: After designing a 3D model suitable for both its desired function and of a geometry suitable for injection molding as above, you saw your model in half and place it on Many-Maker’s casting template. It’s simply a box that mounts the object within their casting frame. Adding a molding compound creates a filled space around the printed object. When the compound solidifies and the object is removed, you now have a custom mold of your object!

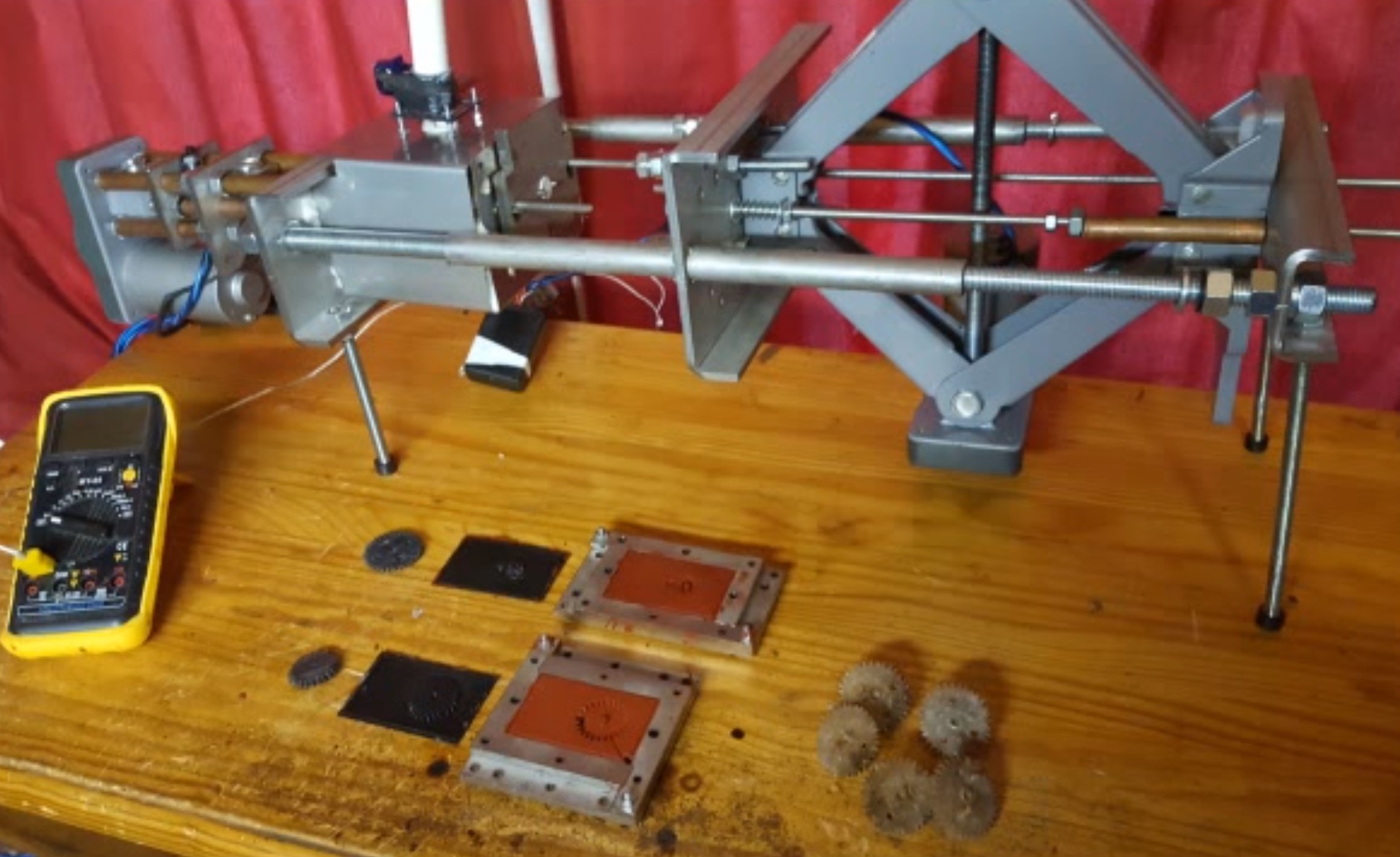

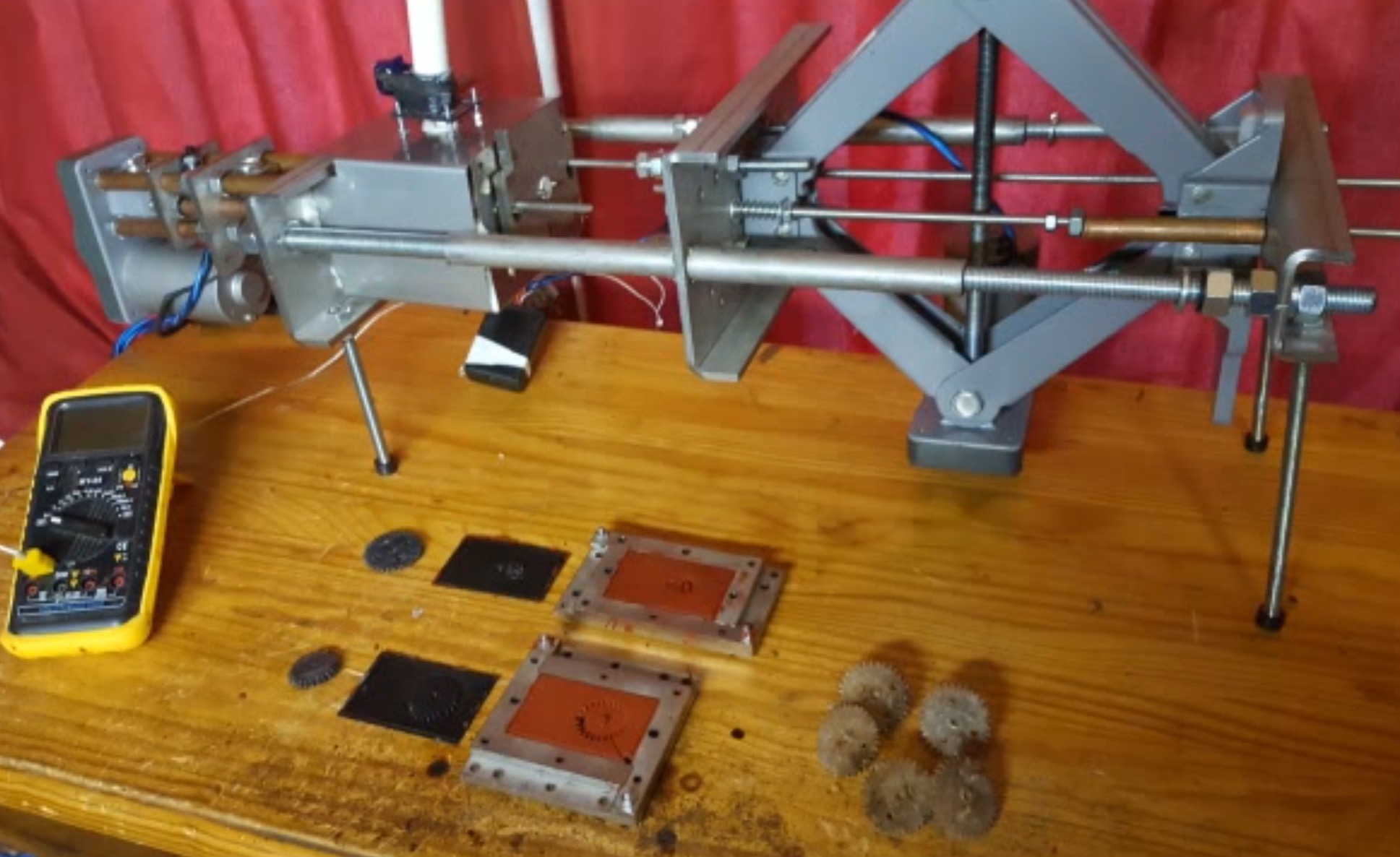

Then this custom mold is placed within Many-Maker’s injection mold press, which squirts the plastic of your choice into the mold, creating a finished object. This process can be repeated many times to quickly manufacture quantities of any suitable object. Even better, you can use very inexpensive plastic pellets instead of the more pricey 3D printer filament in this process.

Many-Maker offers a few different configurations:

- A basic unit for USD$599 that can produce 80 x 50 x 36mm objects

- An automated unit for USD$899 that can automatically eject finished parts and make new ones – like having your own factory!

- A large, automated unit for USD$1,599 that can produce parts up to 150 x 80 x 36mm.

It’s a straightforward process that leverages decades of industrial experience with injection molding, so we expect few issues with this technology. But, as always, one must be careful investing in startups launching crowdfunding campaigns.

The Many-Maker could be hugely important for some 3D printer operators, but for others it may be unnecessary. In fact, Many-Maker describes the machine as “not a consumer product”. But if you are someone who often finds yourself printing dozens of identical prints, this may be an interesting option.

Via Indiegogo