Researchers at the University of Waterloo in Canada have developed a method of 3D printing custom, bio-absorbable bone joints.

The notion of replacement joints is not new; such surgeries have taken place for many years. Everyone knows an elderly relative who has gotten a “new hip”. What they mean to say is that their hip (or other joint) has been replaced with a metal equivalent.

Recently 3D technologies have made this process better by enabling the creation of custom joints, developed by 3D scanning and modeling to exactly match the patient’s requirements. Typically such implants are 3D printed in metal or specialized plastics.

However, these implants are sometimes difficult for the patient as they require perhaps years of recovery, with mechanical and pain challenges along the way.

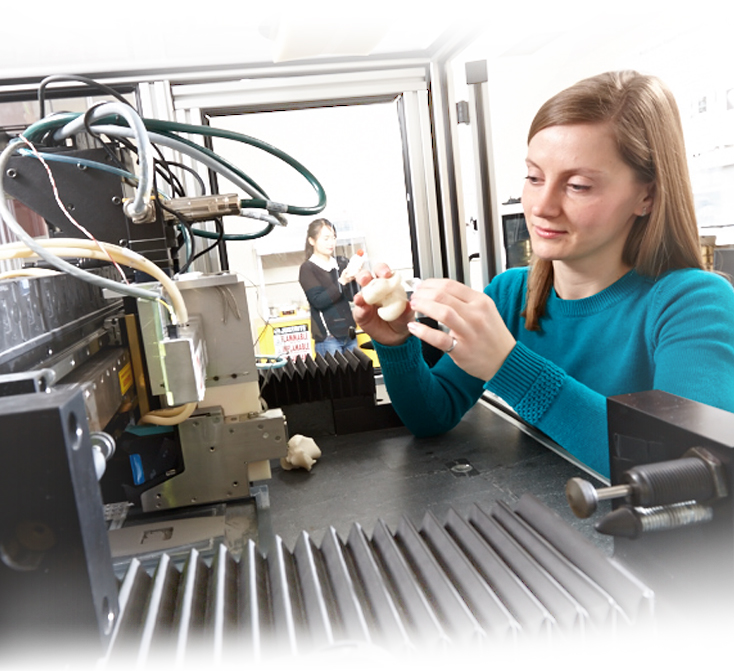

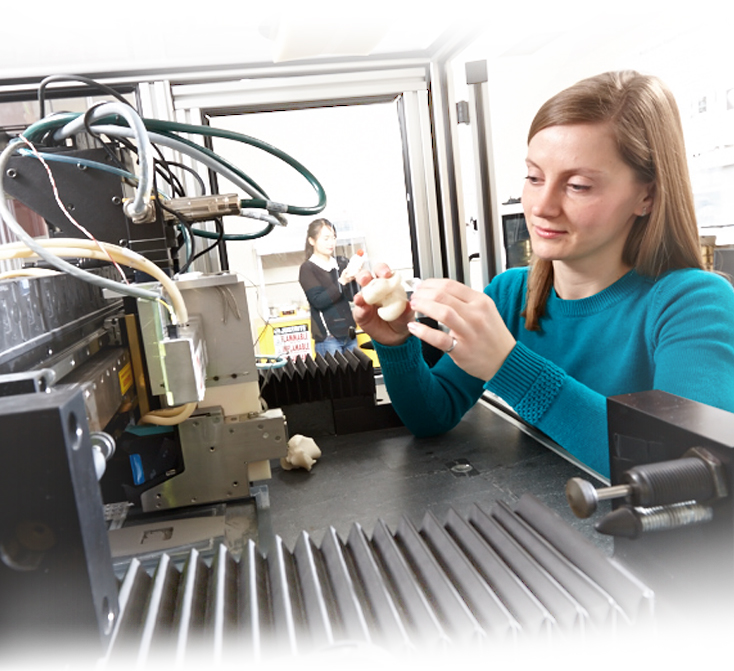

The new research involves 3D printing – in the exact shape, of course – the joint, but in a specially developed calcium phosphate powder. This is done with a newly designed 3D printer specifically for this purpose by U of Waterloo researcher Mihaela Vlasea.

The printer uses the powder-deposition technique, in which layers of powder are selectively solidified. After many layers, you have produced a fragile, but custom object, which requires baking for complete solidification.

After finishing, this print can be implanted into the patient, much like other implants.

But then things are different. It turns out that the material is highly compatible with bone. So much so, that the body actually begins growing new bone directly into the implant! Eventually the implant disappears, being completely replaced by actual bone. This provides the patient with a far superior experience and ends up with actual bone, not implant.

There are many challenges yet to overcome before this 3D printing technology can make it out into the world, but Vlasea and team are working hard on making that happen.

You can listen to an interview with Vlasea on CBC’s Quirks and Quarks where she describes the process and the current state of the research at the link below.

Via Engineer the Future and Quirks and Quarks