A new premium 3D printing hot end nozzle has been developed in tungsten, which could alleviate many issues.

The tungsten nozzle was developed by dddmaterial, a small German company focused on advanced 3D printer hardware, such as the tungsten nozzle. Evidently they’re also working on an “Industrial Extruder”, but it’s not yet released.

Why tungsten? dddmaterial explains that there are issues with the defacto standard nozzles, made from brass and steel.

Brass is the original 3D printer nozzle used for many machines even today. Brass is suitable for this purpose, but when you start doing advanced things with your 3D printer, brass has issues due to its relative softness.

When printing composite materials, such as metal-filled polymers or carbon fiber-infused polymers, these embedded particles abrade against the inside of the brass nozzle, causing wear because the particles are actually harder than the brass!

Over time this can cause the diameter and shape of the nozzle to change, resulting in a permanent disability to your 3D printer’s hot end: the wrong amount of material is extruded and print quality declines.

The usual solution has been to replace the brass nozzle with a steel version, as steel is harder than brass. But there are other issues that dddmaterial believes can be solved with a tungsten nozzle.

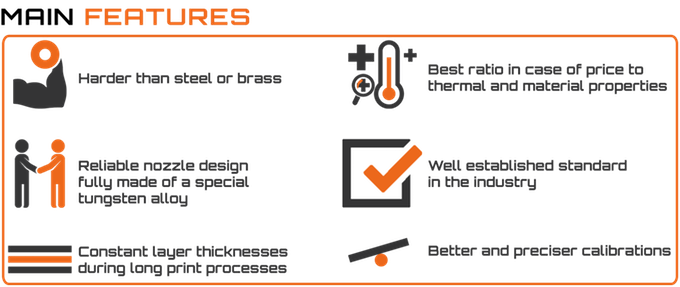

They observed that tungsten nozzles are often used in industrial plastic extrusion settings, and felt that the same benefits gained by industry could be used in the hot end of desktop 3D printers. Specifically, tungsten nozzles provide:

- Increased wear resistance

- Improved heat conduction for more reliable temperature control

- Much harder and reliable

- Low coefficient of expansion

- Resistant to acid and abrasive material

- Low tempering effect

- Does not scratch glass print surfaces (as opposed to sapphire nozzles)

Thus, they’ve produced a practical tungsten 3D printer nozzle made from aerospace-grade metal alloy.

Here’s their video showing the benefits:

At this time their launch campaign is still open, and you can secure a pair of your own tungsten nozzles for €61 (USD$70). That may seem like a big price for a small component (due to the cost of tungsten), but for those doing highly precise or very long prints, particularly in unusual materials, it may be very appropriate.

Via dddmaterial and Kickstarter