Earlier today Stratasys announced their most advanced 3D printer, the J750. But what’s inside this machine that makes it so powerful? We have the story.

As I explained in our earlier story today, the J750 is an evolutionary advance from previous Connex models from Stratasys, but such hardware changes result in a very powerful machine that can provide dramatically more function than any previous 3D printer.

Connex 3D printers from Stratasys use PolyJet technology, which is quite similar to inkjet processes. However, instead of ink, the PolyJet print heads selectively spray microscopic droplets of photo curable liquid resin. A second pass by the print head exposes the fresh liquid to UV light, which almost instantly cures the liquid into solid form. Repeated layers of this process produce solid, 3D objects.

PolyJet technology improved when adding additional resins. First with the original Connex, it was possible to mix two different resins in pre-set combinations. With 2014’s Connex3 technology, up to three resins could be “digitally” mixed to create limited sets of new materials and colors on the fly.

Now the new J750 provides the ability to work with up to six different materials, all at once. It includes six different PolyJet print heads, each using Stratasys’ wide set of industrial resin cartridges.

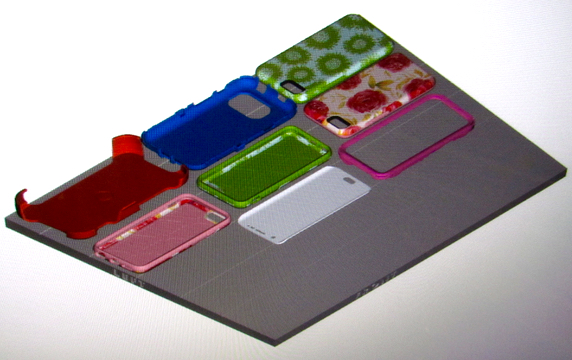

The result of this is a system capable of printing objects with any or all of the following properties:

- ABS-like plastic for injection molding

- Overmolding

- Rigid and soft

- Matte or glossy surface finish

- Finely detailed or large components

- Hard and soft touch

- Smooth and rough textures – in geometry as well as visual

- Ability to “dial in” transparency, color and material properties

- Full color image application

The upshot of this is that you will much more often be able to produce functionally realistic parts for engineers and designers.

The J750 is based on the Connex3 Objet500, as they are visually similar. The J750 has a build volume of 490 x 390 x 200 mm, which is quite large and sufficient to print a wide variety of objects. The print heads are improved over previous models and can reliably produce tiny 14 micron drops at 1800 dpi.

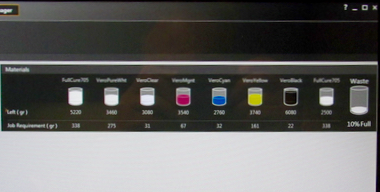

Like the Connex3 machines, the resins are kept in a second cabinet, connected by hoses and signal cables to the main unit.

As seen here, the cabinet contains a great many cartridge slots. There are sixteen in total: two for each of the six print heads, plus an additional four for support material. Two cartridges per material channel enables a “hot swap” during mid-print, should one cartridge run empty. The J750 will automatically switch to the full cartridge, permitting replacement of the empty one. This means you will be able to print very large objects without interruption.

One long-standing challenge with the resin process occurs when swapping a cartridge. To ensure purity of materials, a purge sequence must take place in which the new resin is flushed through the plumbing to wash out all traces of the previous resin. This tends to waste a quantity of the expensive resin.

The J750 alleviates this scenario in two ways. First, having six material channels means you don’t need to change cartridges very often, as the machine likely already is loaded with the materials you need. Also, you don’t need to purge if you replace an empty cartridge with the same material, which is most likely the case with six material channels.

Secondly, the J750 has significantly optimized the purge sequence to reduce the amount of wasted resin.

Regarding the cartridges themselves, they are actually the same cartridges already sold by Stratasys; there are no new cartridges in the Stratasys announcement, and “most but not all” existing cartridges are supported by the J750.

However, I was told that the company is actively working on many new materials for the J750, which we may see emerge in the future. One very interesting possibility could be a conductive resin, making it possible to print devices with embedded electronic traces! However, we’ll have to wait and see if Stratasys is working on such a material.

The J750 is said to print “up to 2X faster”. I asked about how this is accomplished, and is actually a bit complicated.

First you must know that the previous Connex machines had two modes: “digital” and “high speed”. In “high speed” mode, the Connex machines would print faster because both cartridges contained the same material, while in “digital” mode, printing was slower because of the mixing.

In the J750, these restrictions have been removed, and the machine prints as fast as the previous “high speed” mode, even when using mixing digital materials. So the machine itself isn’t mechanically faster than the previous machines, it just lets you run it as fast as it can go all the time.

Is there only one model of J750? For the moment there is only one size and one model. However, I strongly suspect we’ll see variants of the J750 in coming months. Perhaps a smaller version (a “J400”?) with a smaller build volume may be announced. However, there will be a lower size limit as there must be physical space for the six print heads.

Like previous PolyJet machines, you will need some post-processing equipment, namely scrapers to remove the print from the bed, picks and tweezers to poke off support material, and an inexpensive simple water jet system to blast off support material.

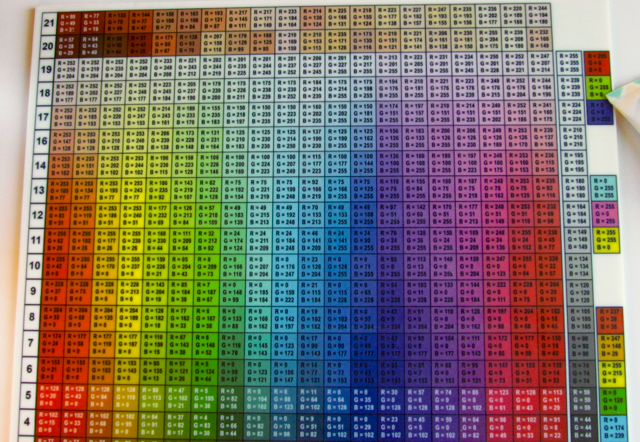

The color on the J750 is astonishing. It’s highly vibrant and can not only be used for “spot color”, as was done in the Connex3, but whole image textures can be applied to surfaces to produce near-photographic results.

The J750 can accurately address the color gamut in all directions from print to print, machine to machine. If you have designed a particular color scheme for an object, you can be sure it will print identically on any J750 using the same type of resin cartridges.

In previous Connex technology, the mixing of resins was accomplished by selecting pre-set mixes from palettes supplied by Stratasys. That changes in the J750.

Here you can specify the exact mix required without the need for a palette. This is a critical feature, as it permits you to generate exact and precise colors. This is important for any color print, because that’s what you want to test: the colors!

So are there palettes in the J750? Well, there can be: the new software does permit copying color configurations from print to print, which is highly useful if you had, for example, a corporate standard color that had to be applied to objects.

All this flexibility enables you to “dial in” the exact solution to your manufacturing problem by adjusting the parameters. And get this – just as you can generate the desired RGB color with a specific material mix, you can ALSO generate specific mixes for non-color materials. Thus, you can print an object with a component that matches the desired flexility or softness or transparency of a production object.

That said, Stratasys does provide some sample palettes to make things easy, if required. However, I suspect most J750 users will prefer the continuous selection tools.

But are there constraints on mixing materials? Could you, for example produce a peculiar flexible translucent brown? I was told that there are some constraints with specific materials, which makes sense. However, you can definitely produce tinted transparent materials.

All of these capabilities are accessible in their new PolyJet Studio software, which is used to prepare the model for printing. I did not get a chance to try the new software, but I understand that it can definitely import UV maps generated by external 3D color programs, such as Adobe Photoshop – and preserve the exact colors in the resulting prints. This means the J750 now becomes one of the three 3D printers capable of producing full color textured surfaces on objects – but it can also 3D print transparent, flexible and other materials, too, which no other machine can match.

The PolyJet Studio software provides a WYSIWYG view of the print job, as shown here. Colorful!

It also shows the machine configuration, which as seen here includes a huge number of active material channels. Isn’t it startling to see all those materials available for any incoming print?

The prints from the J750 I examined were quite astonishing, but this one was quite curious: it’s a fun telescope with an astronomical image wrapped around the surface. It’s also perfectly smooth on all sides.

This, I found curious, because previous Connex technology provided a glossy finish only on the top side of the print; the bottom, the side touching the support material, would always have e matte finish. Had the J750 included a “glossy on all sides” feature? Turns out no, it’s the same as previous Connex machines: glossy on top; matte on the bottom.

So how had the smooth-on-all-sides telescope get printed? It was printed in one piece, but the bottom side was hand finished by lightly sanding it. This can also be done with existing Connex prints, if you want to make them glossy, by the way.

Over the past few months, Stratasys has deployed a few J750’s to selected customers for beta testing. I spoke to one in detail, and the client raved about the power of the J750 and speculated on future uses it enables. More about this in a future post, this one is getting a bit long already.

Finally, one might wonder why the J750 is called the “J750” instead of the “Connex6”, which is really what it is. The answer is this: “J” stands for “Jetting”.

The 750 part remains a mystery.

Via Stratasys