There’s no shortage of ideas for 3D printing startups, but many depend on obtaining custom 3D scan information about clients, and that’s usually a difficult proposition.

3D printing is not the best technology for mass production; it’s too expensive and slow to make a lot of the same things as compared to existing manufacturing processes. However, it does make a huge amount of sense when considering a different application: very small numbers of custom objects.

Thus, many entrepreneurs have sought a way to leverage this capability into a viable 3D print-based business. Some have succeeded, while others have failed miserably.

One obvious requirement for customization is the human body: we’re all different in various dimensions and thus could require customized “stuff” for our bodies. This could mean fashion, medical aids, 3D portraits, functional wear or more.

You’d think you could easily create a business out of that need somehow, but there’s a significant challenge awaiting you: 3D scan data.

Each person is unique, so somehow an anxious entrepreneur must devise a method for obtaining the scan. In the case of 3D portraits, the level of detail required is so immense that “3D studios” must be set up and have customers physically visit to have their scan data generated using expensive 3D scanning gear.

Another possible business would be footwear, in which not only everyone is unique, but there’s a significant comfort factor to be gained if one were to generate “perfect” footwear. But again, how would you get the scan data?

You might devise a kiosk-like device that could be installed at podiatrists’ offices. But that requires customers to make appointments for visits, and also you have to design, distribute and support a physical device. Expensive, lengthy and with no guarantee of success.

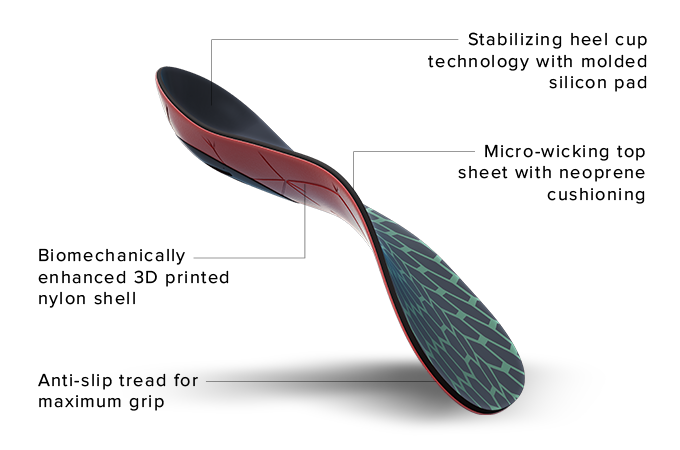

I’ve seen another vastly simpler approach taken to solve this dilemma by 3D printed footwear startup Wiivv, who recently blew up their Kickstarter campaign by receiving five times their campaign goal in funding. Their system produces custom 3D printed insoles that should fit your lower appendages just right.

What was their secret? How do they obtain the scan data?

Their solution is quite straightforward: they deploy a smartphone app, which takes five (yes, only five) pictures of your foot and submits it to their system for analysis. From these five strategically selected images, they are able to generate the correct insole shape.

But this is really what’s going on: they focused the scan problem down to a very precise level. Their goal was to obtain a few configuration parameters necessary to customize the insole. They realized this data could be generated from analysis of a few images, so that’s what they did. There’s no need for complex, “full 3D scans” of the feet. They narrowed it down to only that which was necessary.

This is a successful implementation of a 3D print business pattern: pick a very specific item to customize and then make an extremely easy way to configure it. With correct pricing, you’ve got yourself a 3D print-driven business going.

What other customizable niches might be available using this technique?

Via Wiivv and Kickstarter