Of the many forms of 3D printing processes, resin is one that is seen as advanced – but sometimes there’s a secret issue looming.

Resin-based 3D printing is able to produce objects faster and with finer resolution than practically any other 3D printing process. This is because photo-curable resin can be made solid in segments as small as you can focus a light beam.

Many companies have devised incredible resin 3D printers that leverage this principle, enabling incredibly high resolutions on prints, sometimes so fine you not only cannot see the layer lines on the print, but you can’t even feel them!

Such machines have been adopted by several industries seeking that accuracy, such as jewelers and dentists.

But resin printing isn’t always peachy.

There are two key issues related to resin-based 3D printing that are not mentioned as often as they should.

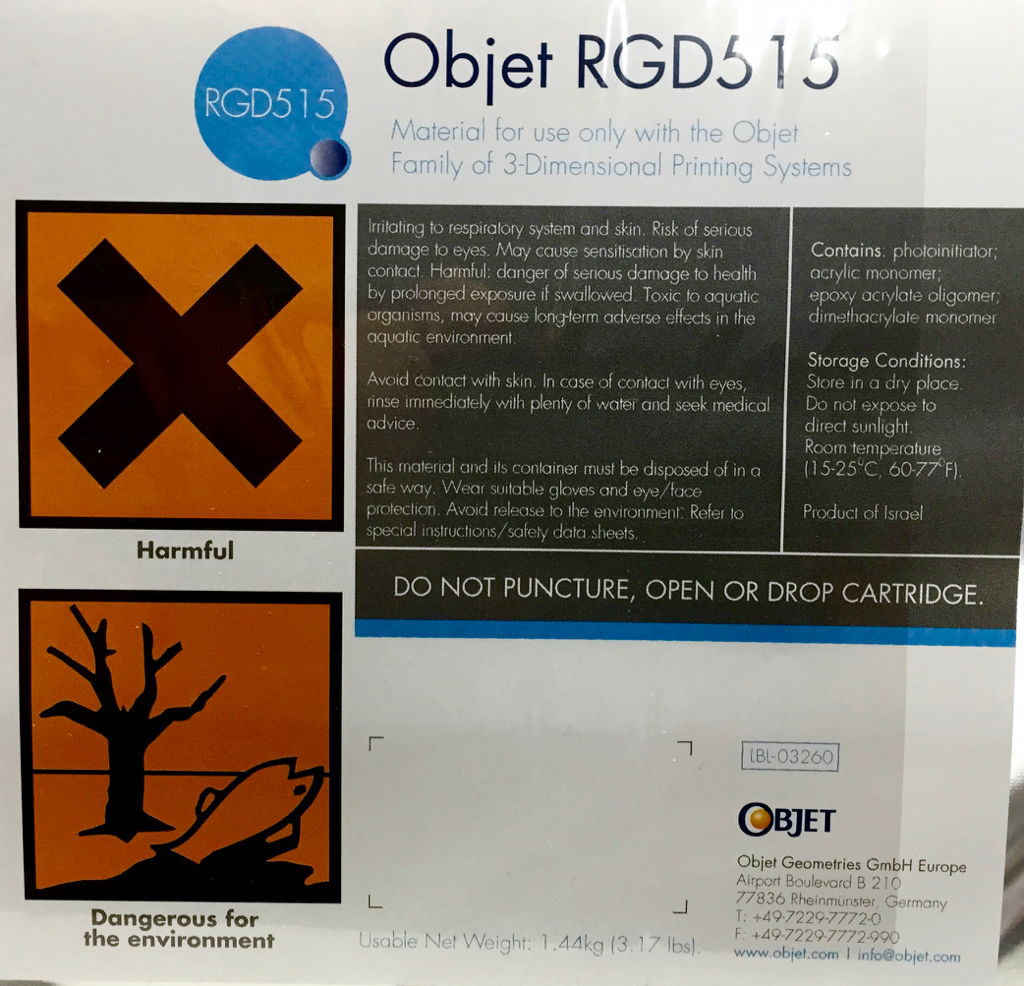

One issue is the safety of the resin. Many resins are actually quite toxic, and we wrote on this some time ago.

This poses problems for operators of such equipment, particularly in non-industrial settings. In the past, resin 3D printers were the exclusive domain of industry due to the cost of the equipment. As such, these machines were most frequently found in proper workshops that have safety handling procedures.

Now, with the proliferation of inexpensive and sometimes quite powerful resin-based 3D printing equipment, such machines are finding their way into less managed environments, where resin safety protocols may not be followed – or even recognized!

I’m paralyzed with thoughts of unknowing hobbyists or newbies working with these machines, bare hands dripping with toxic resin. Run away!

However, remember that some resins ARE safe, it’s just that many are not – and they should be treated appropriately.

The second issue with resin 3D printing is curing, the process that makes the resin solid. While prints emerge correctly from the 3D printer, they may not remain stable.

Why? Because the resin was originally cured (typically) with UV light, the material can remain sensitive to UV exposure.

This means that your resin print, if left outside or exposed to sunlight, could continue to “cure” to the point where it cracks.

Don’t believe me? See the image at top of a resin print, one that’s been around for a while, and it’s severely cracked. Would you like your prints to crack?

The durability of resin-printed objects depends on a few things:

- Subsequent exposure to UV light

- The resin’s chemistry (may be more or less sensitive to this effect)

- How the print is post-processed

That last point is important: consider a resin print that’s been painted. If done correctly, the paint could prevent UV light from ongoing exposure to the object.

It’s also possible that particular resin formulations can provide some level of immunity to this effect.

But it’s something not often discussed.

I’m not saying resin 3D printing is a bad thing, by no means so. Instead, I’m saying that you must be aware of the limitations as you must be with ANY technological process.