Today there are hundreds, if not thousands, of companies operating across the 3D printing industry, all motivated by the potential of additive technologies and/or the commercial opportunities that they offer.

One company that stands out for me in terms of potential and demonstrable progress for the 3D printing industry is the Italian company WASP. This is an organization, that in my view, has efficiently gone about implementing its mission and sharing its vision and ideology with purpose and principles.

Operating as a self-funding project, the WASP vision is big — both figuratively and literally — with an ultimate goal of using 3D printing to sustainably construct global housing using clay with an open source philosophy that promotes equal opportunities and equal knowledge. Lofty aims for sure, but I sense a gritty determination behind these aims, and I admire them.

Many readers familiar with the 3D printing landscape will likely have seen news of the conceptual 12m high 3D printer developed by WASP as part of its ongoing research. However, in order to self-fund this research the WASP team continue to develop contemporary desktop and large frame delta 3D printers, the latest of which has just been announced — the Delta Wasp Pellet.

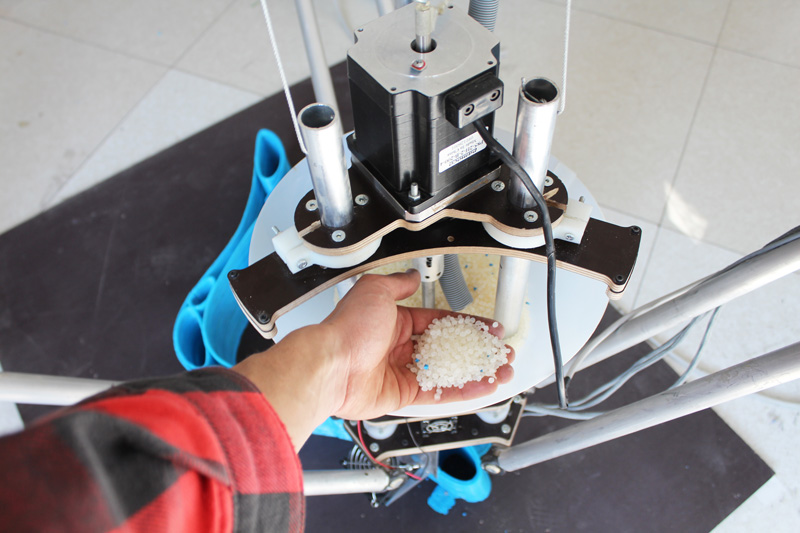

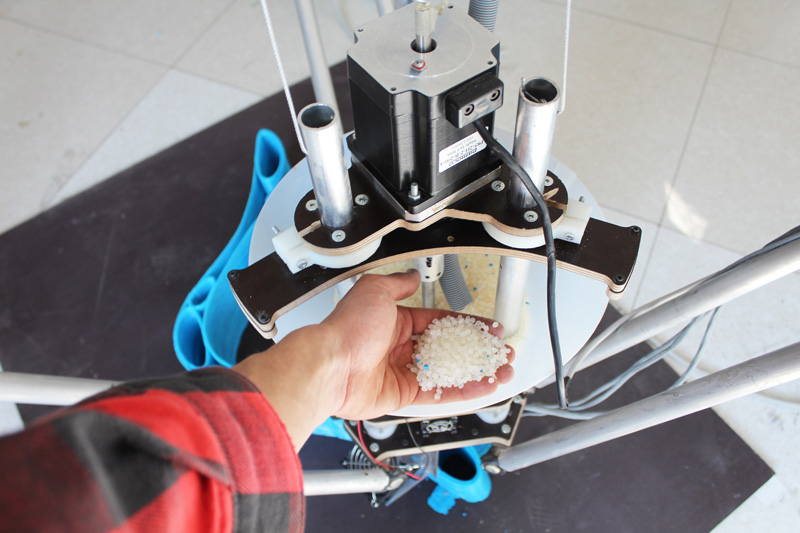

As the name suggests, this platform has been designed to eliminate one of the biggest — and costliest — headaches of the desktop deposition process — filament. As WASP suggests, a single 1kg spool of 3D printing filament costs, on average, €30.

By comparison, the equivalent amount of material in pellet form costs in the region of €3. So, in a similar vein to Arburg’s Freeformer platform (a company that will likely be very interested in this development), WASP’s new DeltaWasp Pellet 3D printer directly processes pellets not filament by way of a specially developed extruder that features a 4-10mm diameter nozzle.

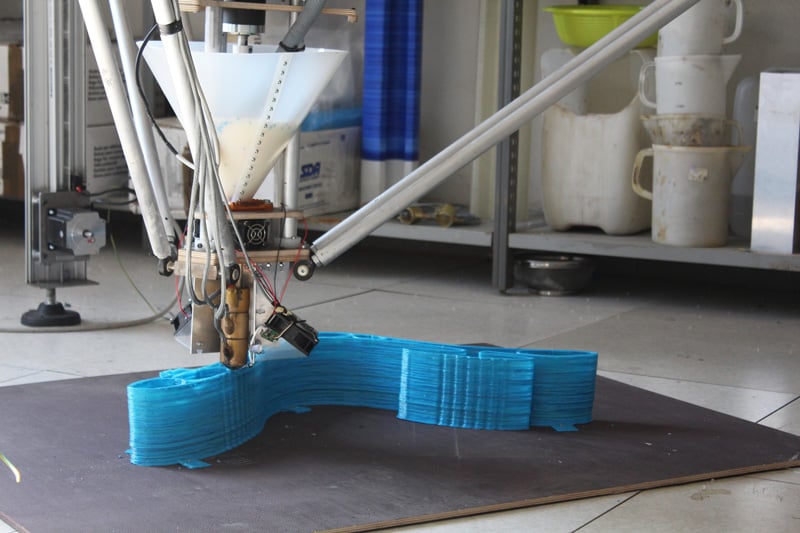

At 3m high, this printer has been designed to print big — and fast — as WASP reports that the DeltaWasp Pellet can process 10 kg of material in 8 hours for a range of large applications, such as the furniture that the company is promoting with this release.

Of course the resolution of the print reflects this, but it also kind of adds to the charm — and the results are not as “messy” as you might expect. The trade-off remains, but what you get, at an economical price point on consumables, might just be worth it.

Ahead of this printer’s release, WASP worked with a select team of designers, including university professors and recent graduates, to develop attractive applications — the work here belongs to design intern Giulio Buscaroli.

Via WASP (Italian)