Most moviegoers leave the special effects to the professionals. Firefighter Ed Zarick, however, was not content with seeing BB-8 rolling around the silver screen of Star Wars: The Force Awakens.

Instead, he had to build his own working replica of the iconic droid. As you might imagine, doing so was no easy task, as Zarick had to overcome a number of engineering hurdles to bring BB-8 to life. Fortunately for other fans of the film, he’s not only pulled it off, but Zarick has also made the project open source, providing all of the details for constructing his remote-controlled BB-8 bot online.

Since BB-8 made its debut in the very first trailer for The Force Awakens, there have actually been numerous attempts to recreate it, most notably by a Facebook group called the BB-8 Builders Club. Inspired by the efforts of the group’s 10,000+ members, Zarick sought to improve upon their designs to make his own model of the droid as functional and accurate as possible. The end result is nothing short of amazing, filled with all of the flashing lights, whistling sounds, and even BB-8’s signature rolling movement that’s made him so popular among moviegoers. But how did he manage to get to this end result?

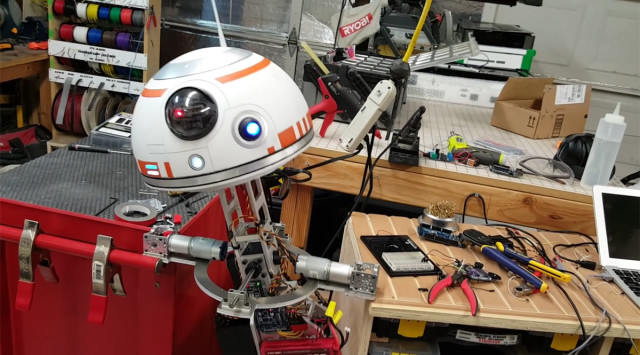

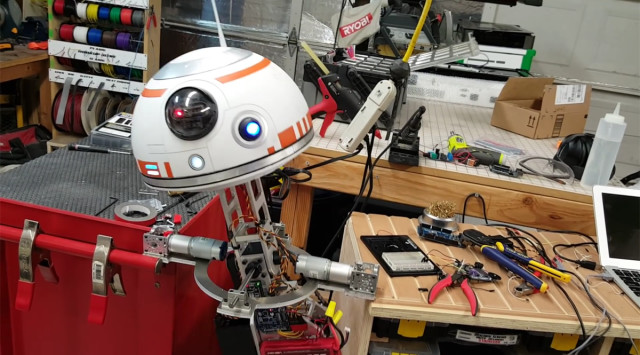

To begin with, Zarick was standing on the shoulders of giants, as the BB-8 Builders Club had already designed 3D-printable CAD files for building the bot’s head. When it came to making thisfloating dome, all he had to do was set his infill to 100 percent and click “print” so that one of his MakerBot Replicator 2X 3D printers could fabricate the parts in ABS plastic.The body, however, is a 20-in. polycarbonate sphere, sourced from California Quality Plastics and priced at roughly USD$500.

To those more interested in the interpersonal dynamics of (possible) Star Wars couple Rey and Finn, the mechanics of how BB-8 moves may not be fully appreciated at first, but, upon further consideration, it really is amazing to see a robot whose body rolls in every direction while its head moves with it. Attaching the head to the body, Zarick points out, is not the most difficult part of making BB-8 move. The dome-shaped head is simply connected to the body with magnets, one at the base of the dome and another attached to a column within the sphere below.

Zarick’s biggest contribution to the BB-8 project is the drive train, which is a simple and elegant solution to what could potentially be a complex problem. While other BB-8 builders have implemented a “hamster wheel” design, as Zarick calls it, for moving the bot, this builder has used a single axel with a counterweight. The hamster ball setup, he explains, would see a motor drive a set of wheels inside of the sphere, pushing the body the same way a hamster pilots a hamster ball.

In fact, this is how the Disney BB-8 toy designed by Sphero operates. Two wheels, attached to a hefty set of electronics, drive the small remote-controlled gizmo forward. A weight at the base keeps the ball level, while a mast, jutting out of the axel joining those two wheels, is connected to the head by magnets.Scaling that design up to the size of the actual BB-8, however, is much more difficult than one might think, according to Zarick. He says that there is too much weight for the hamster wheel setup to handle.

When BB-8 made its first public appearance at Star Wars Celebration 2015 in Anaheim, California, ahead of the film’s release, Zarick was sure that he could see an invisible single axel driving within the body of the bot, with a counterweight hanging below it. At the other end of that weight is the magnet, attracting BB-8’s head to its body.

This whole design results in a system in which, as a motor spins the counterweight in one direction, the ball rolls in the other, with the head exactly opposite to the counterweight.In this way, Zarick’s system is much simpler than the hamster wheel setup pursued by other builders or even the Sphero toy. It also left him with plenty of room to embed lights within the sphere, without the risk of a robotic hamster-equivalent running them over.

The internal mechanics of Zarick’s BB-8 are made up of a handful of motors, mounts, bearings, shafts and pulleys. Just about everything else was custom milled in quarter-inch aluminum with the firefighter’s own CNC machine. To support the necessary weight to drive the BB-8 forward, he milled braces that run parallel to the main mast of the system. A spin motor at the center of the mast spins the pendulum one direction, so that the ball moves in the opposite direction. All of this is connected to the main carriage of the droid, another component Zarick cut from aluminum himself.

The head of BB-8 slides along its spherical body thanks to the counterweight pendulum within, but to really give it life, it needs to spin on its own. To provide BB-8 with a magnetic neck, a continuous servo motor is attached to the magnet within the droid’s body. As this motor rotates, so does the magnet, which causes BB-8’s head to rotate on the other side of its big polycarbonate body.

Read more at ENGINEERING.com