I’m viewing a very curious video from Tokyo-based ENOMOTO, who seem to have developed a 3D printer that can print in many directions.

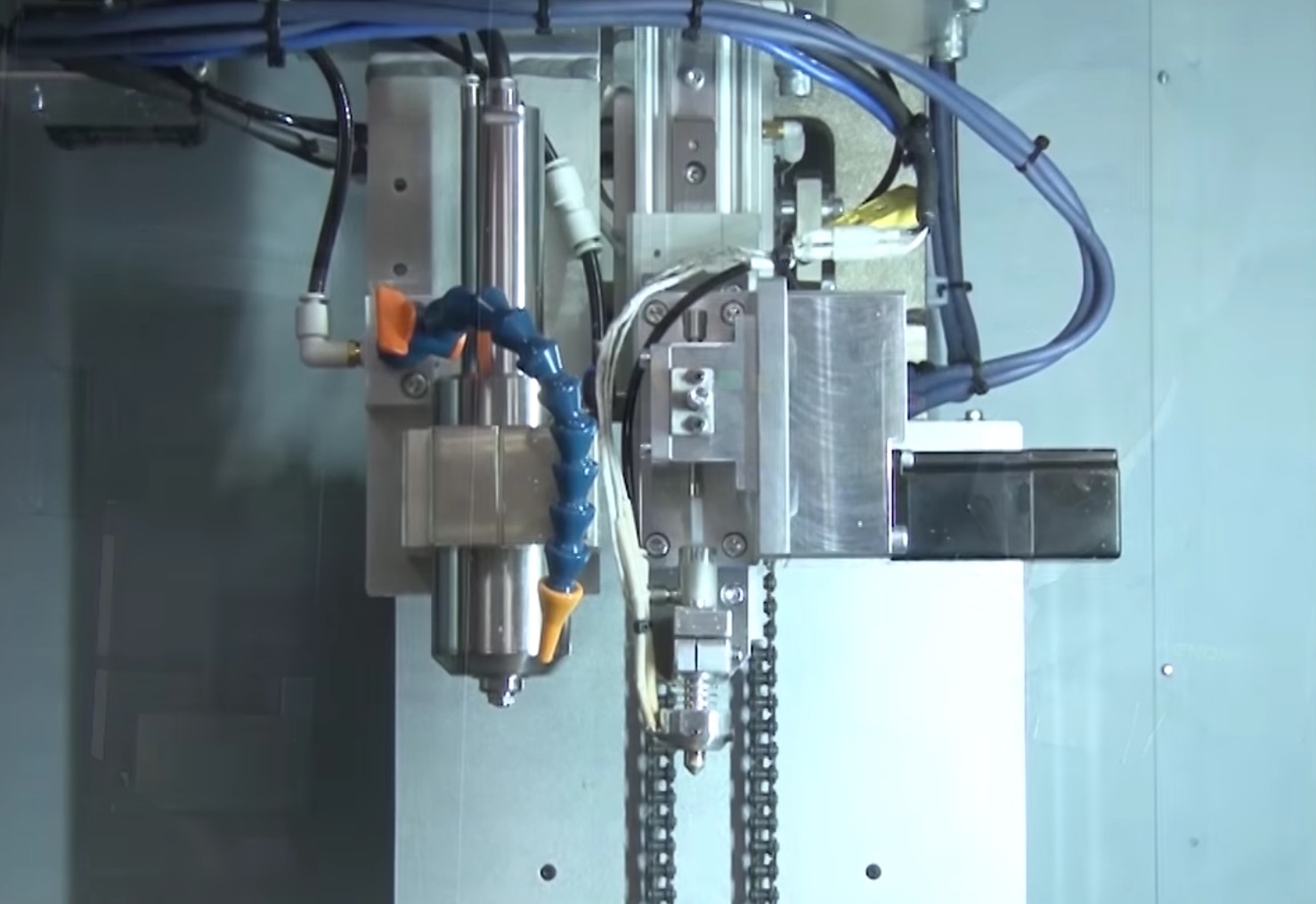

It’s a hybrid device that combines a 3D printhead with a 5-axis CNC milling component. A CNC mill uses a high-speed bit to cut away material and is commonly used in manufacturing.

I’ve seen this before: at a Euromold a few years ago, I saw DMG MORI’s hybrid 3D metal printer, which would print the metal object, and then mill its surface smooth with the CNC.

It seems that the ENOMOTO device, the 3D5X-a hybrid machine, could do the same, except using plastic instead of metal. Smooth plastic surfaces from 3D printed objects. That’s not particularly amazing, because you can achieve smoothness in other ways.

What’s more interesting is that the ENOMOTO 3D printhead is attached to the CNC 5-axis motion control system. This means that the printhead can move not only in X, Y and Z dimensions, but also in other directions.

This means that the machine can print layers in other directions! They say in the video:

This machine is capable of not only planar lamination, but also 5-axis lamination.

It’s an intriguing idea that could enable several new ways to 3D print plastic:

Support material could be simplified or even eliminated in some 3D models, as the print can be tipped appropriately for plastic deposition on what would otherwise be extreme angles. However, some geometries would still require support material.

Another interesting aspect is that the layers could be printed in ways to provide maximum strength to the object. Normally, the weakest point on a print is where layers join, and if you’re printing in “planar” mode, you don’t always have a choice as to how the layers appear in the print. With this technology, it might be possible to tip the model during printing and print layers along stressed sections for added strength.

While these are terrific ideas, they would require considerable effort to figure out the software algorithms to generate such complex movements by the 5-Axis 3D printer.

Indeed, the video does not actually show the 3D printhead moving in anything other than the usual 3 dimensions, and all of the sample prints appear “planar-printed”. Perhaps ENOMOTO hasn’t got the software figured out yet.

And perhaps that’s why the machine isn’t expected to be sold until sometime in 2017.