The BeeHex is a specialized 3D printer designed to do only one thing: print pizzas. But why?

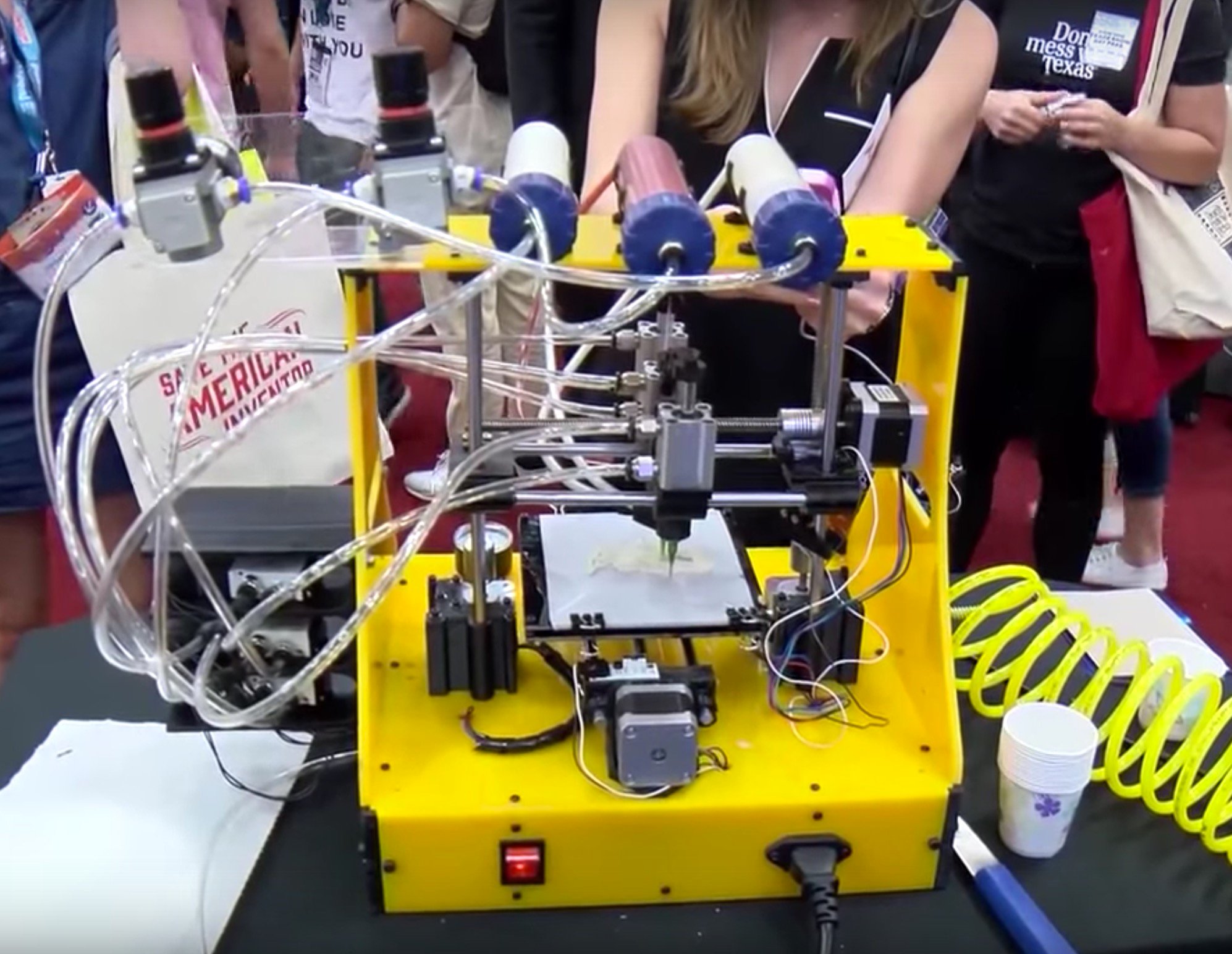

I’m looking at something called the BeeHex 3D printer, which apparently produces 3D printed pizza. The company describe the function as follows:

BeeHex uses robots to make high-quality pizza from the finest ingredients. BeeHex pizza is made by clean robots. The pizza is not only visually appealing but delicious, creating excitement among chefs, restaurant chains, theme parks and major food brands.

Ok. So how does this work, exactly? It seems they’re using a three extruder approach to selectively deposit combinations of: dough, sauce and cheese.

Watch this video to see it in action:

As you can see, it deposits a layer or three of dough, followed by complete coverage of tomato sauce. Finally, what looks like shredded cheese is squirted on top. It’s definitely a pizza.

A cheese pizza.

Then the print is placed in a conventional oven for cooking, followed by a few bites of eating.

I am totally confident this works and works very well.

However, I am baffled by the practicality of such a device. There are numerous problems:

Pizza size is relatively small, perhaps smaller than the smallest pizza you could order. The size is likely limited by the multiple extruders, each of which subtracts a bit of X-dimension from the print volume.

There are only three ingredients, meaning you can only make Cheese Pizzas. Yes, yes, we all love Cheese Pizzas, but JUST Cheese Pizzas? Ok, you could make a cheese / pesto sauce pizza, but that’s about it. There is no accommodation for other ingredients.

Proper pizza dough requires a very precise chemical and temperature sequence. Pizza aficionados would be challenged to see the BeeHex’s dough as appropriate.

The BeeHex can 3D print pizzas in only four minutes, according to the company, as opposed to the nine minutes required by humans. Well, just hold on a second. Does that four minutes include the time required to prepare the dough, sauce and cheese for loading into the pressurized canisters on top of the BeeHex? I suspect that it would be quicker to just make the pizza yourself than setting up and running the BeeHex through its normal sequence.

The pizzas produced are not actually “3D”, other than there are a couple of layers. They’re actually just 2D structures that cannot take true advantage of 3D aspects. Why? Because the build materials (dough, sauce and cheese) are not sufficiently strong to support anything other than a flat structure. The implication of this is that the BeeHex can only print flat pizzas that are little different from any you could easily make yourself.

Food printers require special design to ensure food safe production. This requires not only food safe material path, but also an ability to properly – and easily – clean all food-contaminated components. While I’m pretty sure the BeeHex is made from food safe parts, it’s unclear whether the maintenance procedures are easily performed. Again, this must be added to the time required to operate the machine.

The machine requires a source of compressed air, which is not typically found in consumer kitchens. This could be provided by an active compressor (with associated noise) or by a tank of compressed air that would have to be replaced periodically. Neither of these approaches are reasonable for a typical kitchen.

The BeeHex has three ingredient canisters installed on top that fuel the printing. One possible advantage to using this approach would be to print multiple identical pizzas in quick succession. However, the size of the canisters suggests you could only do a few at a time before reloading is required. Worse, you’d have to wait four minutes X the number of pizzas required before you can start cooking them, otherwise your diners will receive pizzas at different times.

Some 3D food printers might be appropriate for industrial kitchen use, but the BeeHex is configured for personal use, so it is unlikely a kitchen would acquire one, except for novelty purposes. Consider that the amount of pizza volume a normal kitchen can produce with its massively sized pizzas in a given time versus what a BeeHex can do. It doesn’t have sufficient volume for commercial use.

The BeeHex is apparently available for purchase, but we don’t know the price. Evidently you must contact the company for a demo and go from there.

I don’t think I will be purchasing a BeeHex anytime soon, but the concept does seem to attract a lot of attention. Why so? I think it is because everyone really wants a device that can make interesting food at the touch of a button. For many people, cooking is a chore they’d prefer to automate.

However, current food printers are slow and print only simplistic structures. Someday it’s conceivable someone will invent a true chef-quality food printing device.

But the BeeHex isn’t the one.

Via BeeHex