About 30 years ago, 3D printing began as a technology for rapid prototyping, allowing designers, engineers and manufacturers to quickly produce physical mockups of their designs.

As 3D printing matures, however, it’s growing into a method for actually manufacturing end parts in a wide variety of materials and across industries.

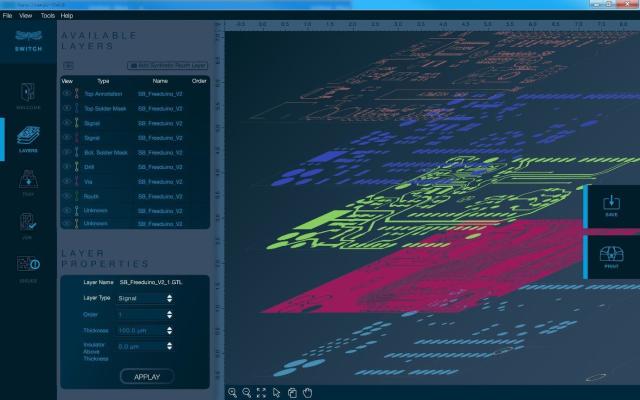

Similarly, Israeli firm Nano Dimension has entered the manufacturing space with a technology capable of rapidly prototyping multilayered printed circuit boards (PCBs). At the moment, although not yet commercially released, the DragonFly 2020 3D printer can 3D print PCBs so that engineers and manufacturers can iterate circuit board concepts more quickly and affordably than they would through traditional methods. In the future, however, it’s easy to imagine this technology evolving to 3D print end parts—in this case, fully functional electronic devices.

In an interview with ENGINEERING.com, Simon Fried, CBO of Nano Dimension, spoke as to the company’s technology, where it’s heading and the benefits he sees PCB 3D printing bringing to the manufacturing industry right now.

What Does It Take to 3D Print a Circuit?

In speaking with Fried, it became clear that the DragonFly 2020 really is a 3D printing platform, but one that has been specialized for the 3D printing of PCBs. The system deposits inks similarly to inkjet 3D printers on the market. While one of these inks is still a photopolymer, as seen with Stratasys’ PolyJet or 3D Systems’ MultiJet, the other is made up of highly conductive silver nanoparticles.

The DragonFly 2020 jets these two materials layer by layer, beginning with the underside conductive traces and ending with the topside conductors. The result is a functioning circuit board. Once all auxiliary electronics are added, such as transistors and resistors, users can begin testing their PCB concepts.

“We realized from the beginning that inkjetting was the key technology for this application,” Fried explained. “There are a few areas where we see the technology as being a strong one. The printers most capable of multimaterial 3D printing are inkjet 3D printers. In the future if we want to increase the speed and size of such a system, we can add more printheads.”

Read more at ENGINEERING.com