Canada-based ORD has been developing plastic mixing technology for some time now and the result is the very unusual RoVa4D Full Color Blender.

While there’s several interesting features included in the 6th generation RoVa4D Full Color Blender, the most notable is its ability to mix colors. It works on the same principle as 2D paper printers: CMYK (mixing Cyan, Magenta, Yellow and Black). Technically, you only need a mix of three colors, CYM, to create any color. However, the 2D paper guys had to add “K”, or black, because the CYM “blacks” were often quite muddy in appearance. Similarly, the RoVa4D adds not only a dedicated black but also a dedicated white filament.

That’s correct: this machine uses up to FIVE different filaments simultaneously.

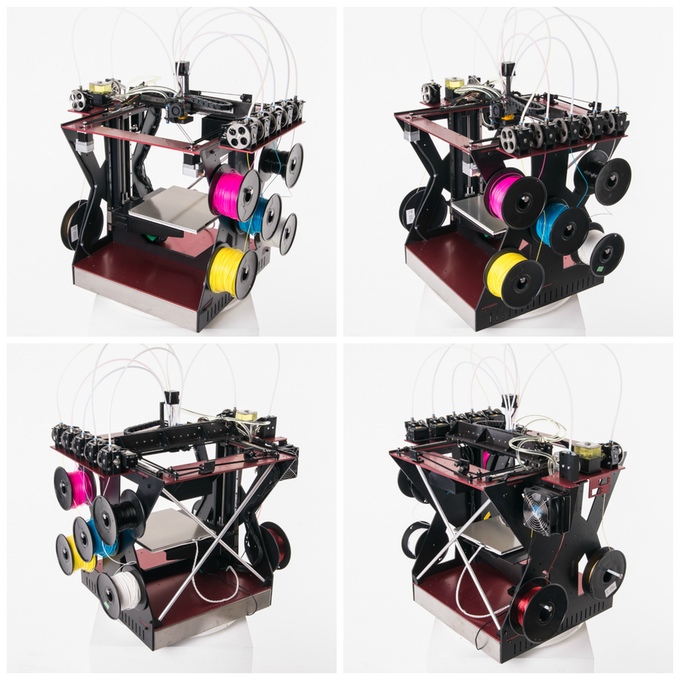

As you might imagine, the spool rack is busy.

There have been many attempts at mixing filament before, but the results have usually been poor, because the mixing occurs slowly compared to the rate of extrusion. Usually such machines will show a very gradual color switch over the course of several 3D printed layers. Interesting, but not particularly useful.

It seems that ORD has been working on the color switching mechanism, as they’ve already had a five-filament machine in previous generations. They explain:

This lets you print unlimited colors in a single print. The materials can be 3D printed with a gradient or as hard separations. The printer switches colors by purging the difference in a little bin (just like your inkjet) or to reduce the waste the transition can happen inside the infill area of the print provided that it’s large enough.

Hardware-wise, the RoVa4D actually includes three hot ends. One is used for mixing up to five colors, while the other two are used for dissolvable support material for complex geometry prints, and the third is specially designed for extruding challenging flexible filaments, such as NinjaFlex.

And these two dedicated filament extruders are IN ADDITION to the five colors, making this machine in fact a SEVEN filament device.

With these extrusion mechanisms, it seems the RoVa4D can cover all the bases: Single color, multiple colors, mixed colors, support and flexible material.

Color mixes are actually calculated automatically by ORD’s software. You can select a color from a palette and the system decides how much of each color filament is required to produce the desired color.

This is NOT a system where the colors simply change on layer boundaries as so many other color mixing systems do. Instead, you can “paint” a 3D model’s surface with ORD’s software and the machine will automatically print the model with the required colors as shown here.

And there’s more: the machine is designed to handle a very wide array of filament materials through its heated print surface and the high temperature hot ends (up to 450C) and fully enclosed build volume.

But here’s the really interesting thing: with all this filament capability available on the RoVa4D, you can actually attempt to mix different materials on the fly to create new properties. For example, you could mix a hard and soft PLA filament to extrude a material with a different hardness. Or perhaps you could mix a metal-infused PLA filament with a wood-filled filament to create something very unusual. The possibilities are obviously endless.

The build volume is significant at 300 x 300 x 300mm, and it’s built from stiff aluminum.

There are tons of additional features on this amazing machine, such as integrated WiFi networking, a touch screen, automated bed leveling, liquid cooling, high-quality mechanical components, quick change bed, individual nozzle lift to avoid unfortunate print crashes and there’s even an integrated power supply to eliminate the huge power brick found on many other machines.

You’re probably wondering how much this machine costs, and the early-bird campaign price is CAD$4,500 (USD$3,400) for the first batch. However, as they run out, the price will rise up to CAD$4,800 (USD$3,600). This is an exceptional price level for a machine with such features. As of this writing, there are many units available, but note they’ve already smashed through their modest campaign goal, so these machines may go quickly.

I’m very curious to see how well the color switching technology functions, and hopefully we’ll be able to get one in our lab for testing.

Via Kickstarter and ORD