For years there has been a significant gap in quality between industrial and “hobby” 3D printers, but it’s becoming a more difficult to measure.

I’m reading an interesting investigation on Mike Skrzypczak’s Additive Part Design in which a single part is printed on a high-end industrial 3D printer (in this case a Stratasys Fortus 380mc) and a typical “hobby” 3D printer, a LulzBot TAZ 5.

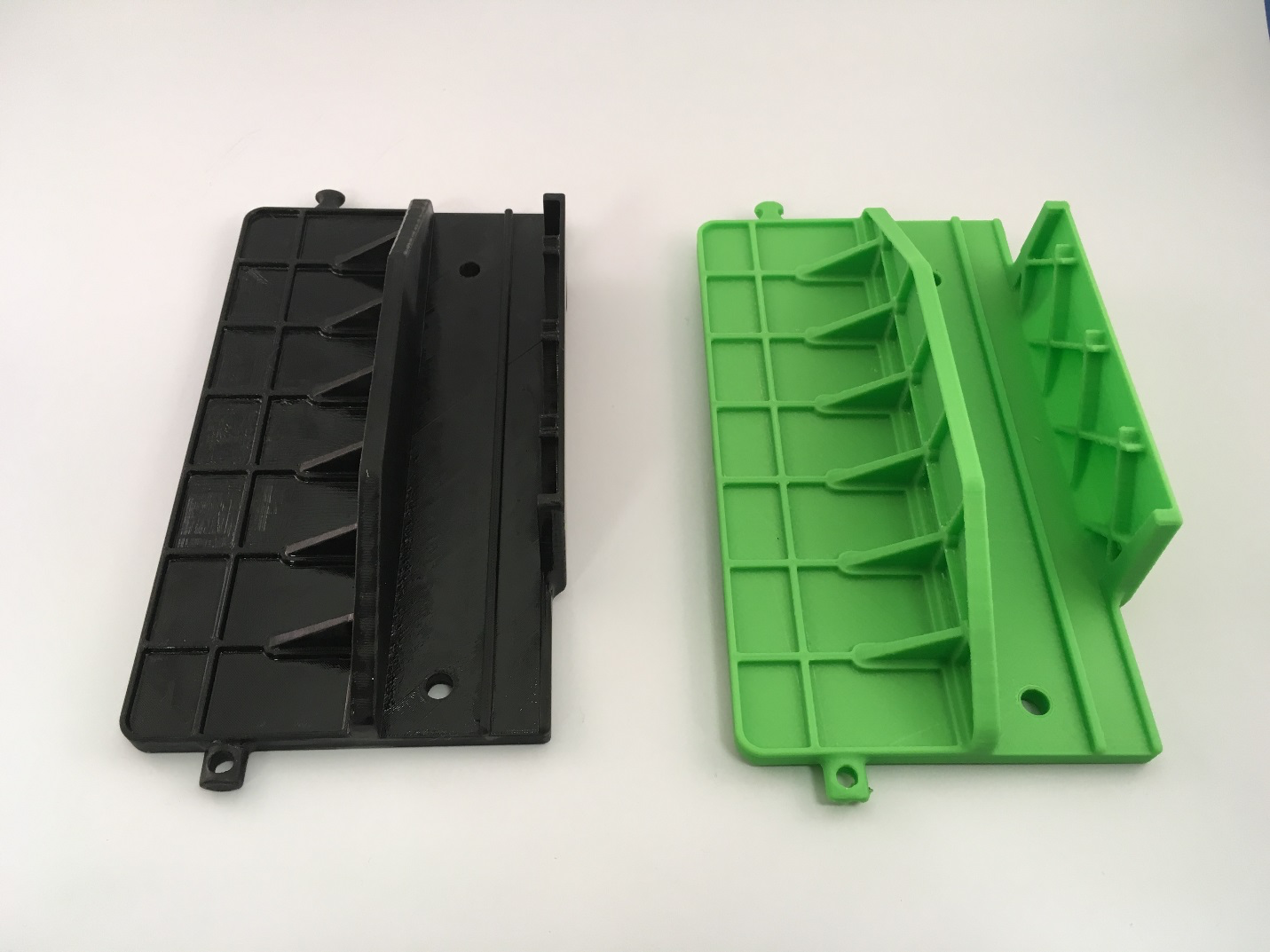

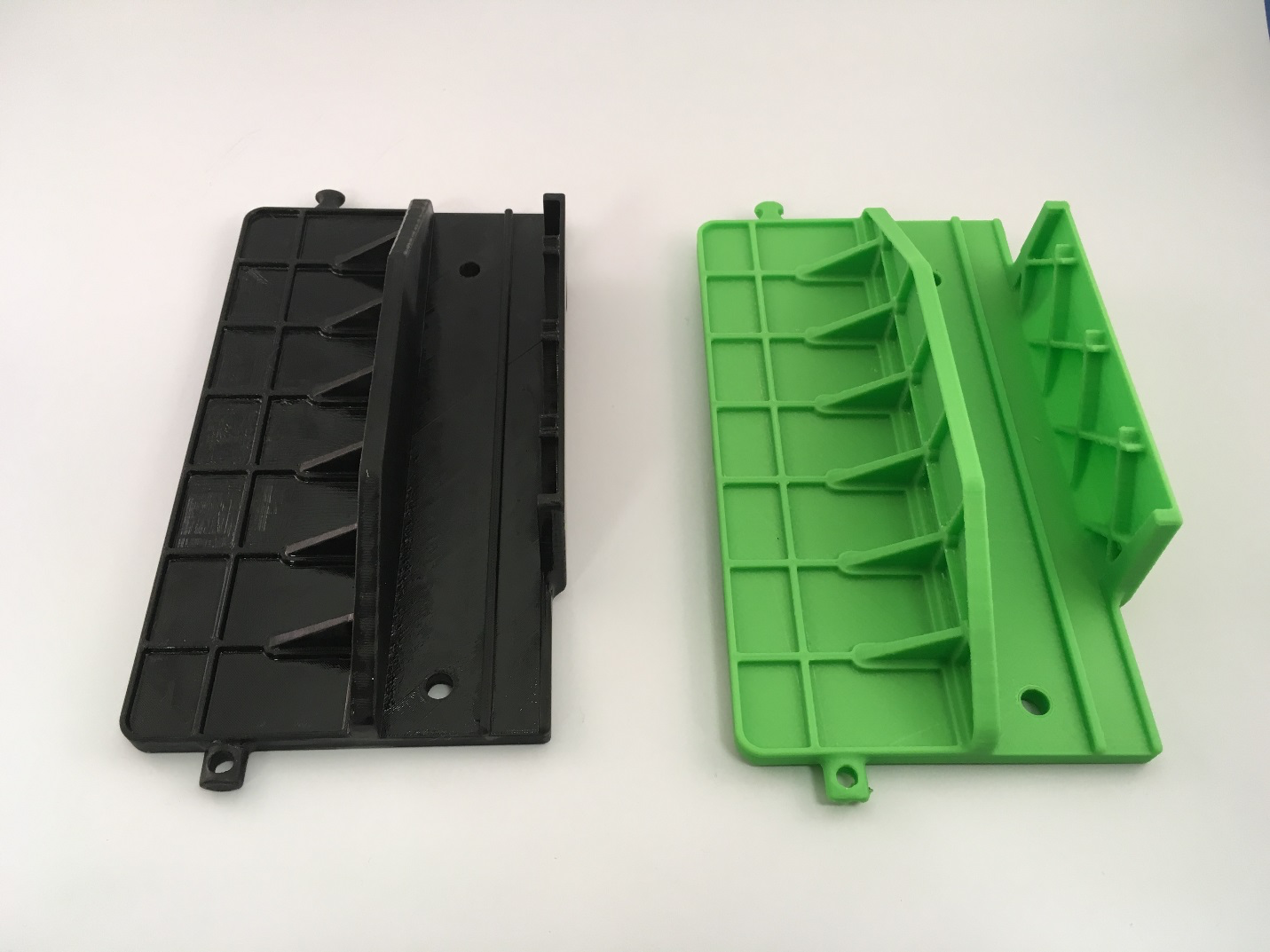

While I won’t go into the results of the APD investigation, which you can read at the link below, you can see the two printed parts in the image at top. The “industrial” print is on the left in black ABS plastic, while the “hobby” print is on the right in green HIPS plastic. Skrzypczak says:

My initial reaction was that the overall top layer surface finish was very close. The Stratasys printed part was better. But in all honesty, not obviously better.

And that statement illustrates the situation: the so-called “hobby” desktop 3D printers are gradually approaching the quality of the much more expensive industrial machines. From the initially poor-quality experimental desktop machines of eight years ago, huge progress has been made by many 3D printing startups. Now it’s possible to purchase filament extrusion desktop machines that actually exceed the resolution offered by some of the major industrial players.

But does this mean you should not buy the expensive machines and get your work done on more inexpensive machines?

Not necessarily. There are several factors beyond mere print quality that should be of interest to businesses seeking 3D print capabilities.

A major consideration is endurance, where the industrial machines tend to be designed for continuous, long-term operation. The machines can be made with higher-quality components and have design features that permit near-continuous operation. That’s often not the case on less expensive desktop machines.

Another consideration is operational ease. Industrial equipment in a large workshop must often connect with other existing systems and procedures, and very often high-end 3D printers are designed to do so. They will, for example, include remote control capabilities, including video. Another critical feature is the ability to provide a definitive activity log from which billing and costing can be developed.

Finally, there is the issue of support. Businesses operating 3D printers must receive significant support from the manufacturer to ensure their valuable 3D printer is maintained and operating as much as possible. To do this, industrial 3D printer manufacturers maintain squads of field engineers trained on the equipment, who can show up at a site in person to repair any issues. Similarly, they’ll also provide a central support site with the most highly-trained experts to support the field engineers. Added to all this, the industrial machines can often transmit equipment status, diagnostics and logs to central support for analysis.

If all you’re seeking is quality, then by all means consider a desktop machine. But if you require endurance, operations integration and very comprehensive support, then you might consider pursuing a more expensive industrial-level 3D printer.