Researchers at Rice University and the National High Magnetic Field Laboratory have developed a startlingly hard material, Ti3Au.

One of the problems they’ve been focusing on is the development of a material suitable for medical use. As some metals are toxic, it is critical to use a safe material for invasive medical procedures where metal contacts – or is embedded in – a human body. Evidently Titanium quickly builds up an oxide layer that insulates it from bodily functions.

For years, that material has been Titanium, and in fact Titanium is a very popular 3D print material: many metal 3D printers are able to solidify finely powdered Titanium into medically-certifiable objects.

The problem is that Titanium is not sufficiently strong to be used in some intended medical procedures. The researchers sought a harder material that was equally safe to use in medical situations.

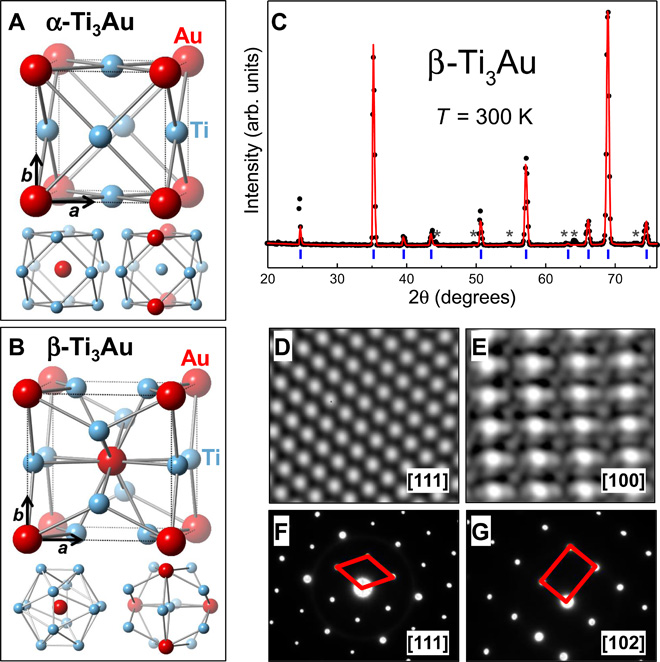

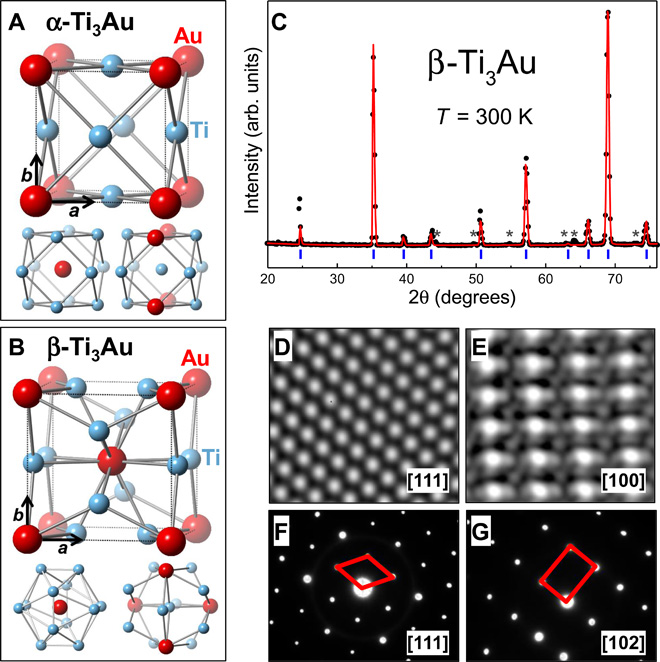

The researchers found that a particular alloy of Gold (Au) and Titanium (Ti) resulted in a material that was four times the hardness of previous Titanium-Gold alloys!

Even better, the new material has the ability to adhere to ceramics, making it suitable for some interesting applications.

Their research paper makes no mention of using the new material in 3D printing, but it seems to me that it would be a natural thing to do so.

The material would have to be converted into a suitably fine and uniform powder for use in existing thermal-based metal 3D printers, but that should not be a problem for powder vendors, who have often made unique variations.

If they do so, then the strong medical devices imagined by the researchers could be 3D printed directly.

Via ScienceAdvances