Who knew that one of the most amazing metal 3D printing technologies is hidden in Sweden?

I spoke with representatives of Höganäs, a somewhat mysterious Swedish firm that got its start in the 1700’s mining coal.

Today they specialize in the production of finely powdered metals for use in popular metal 3D printers, and a large number of other metal-related products and services. The 3D printing machines using their powder would typically employ powerful lasers or electron beams to fuse the powder into solid metal objects.

But there’s another product Höganäs has been developing: a metal 3D printer using a unique technological process that produces astonishingly detailed 3D prints. They call it “Digital Metal®”.

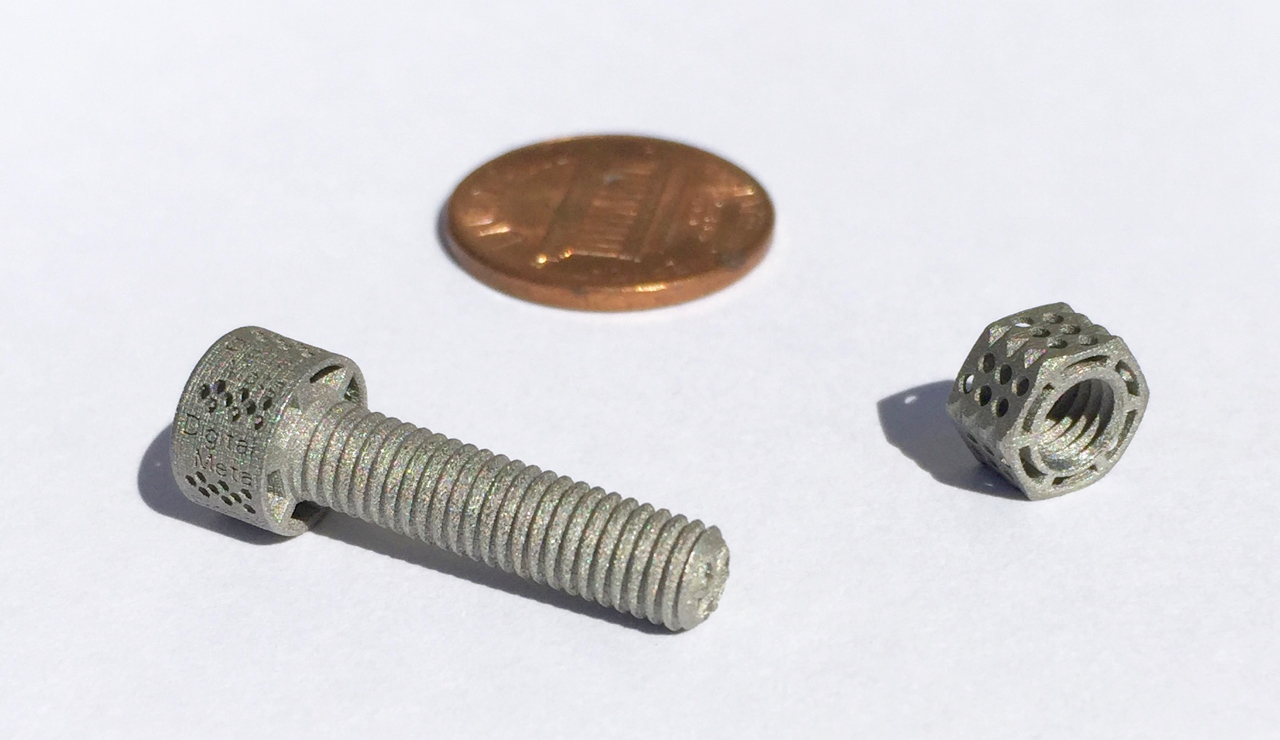

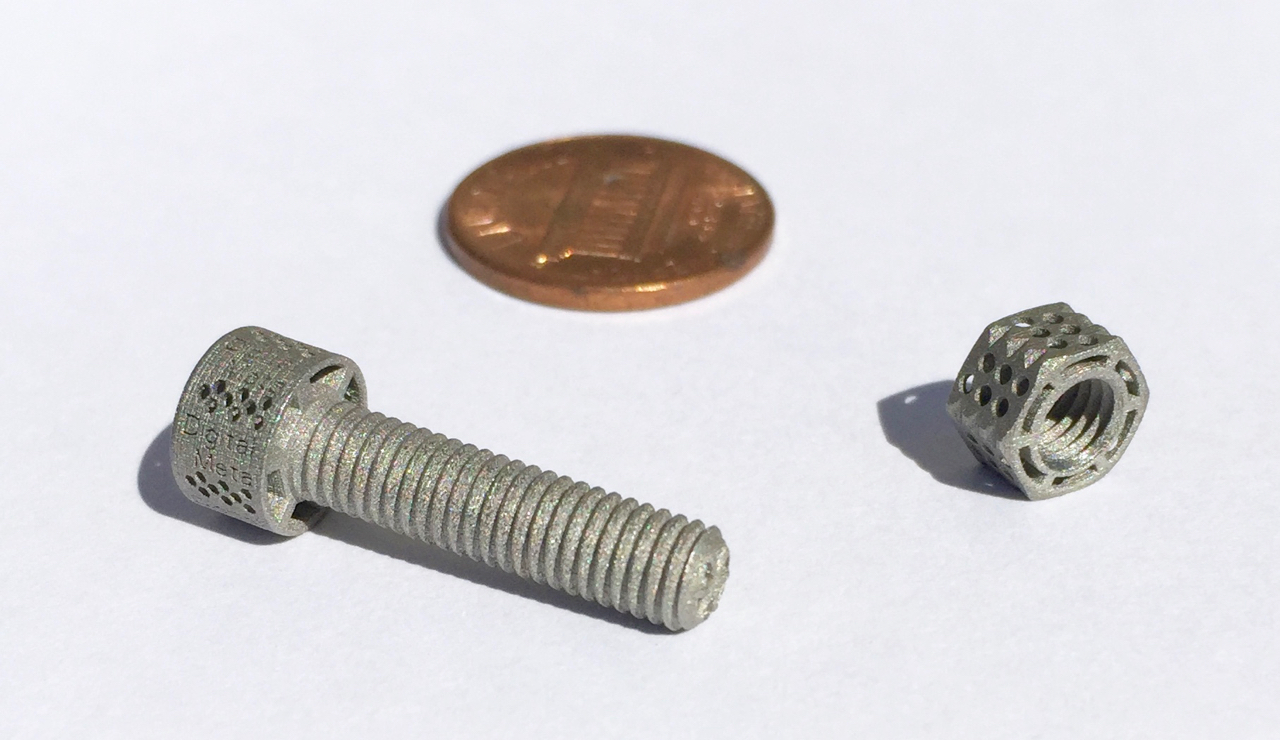

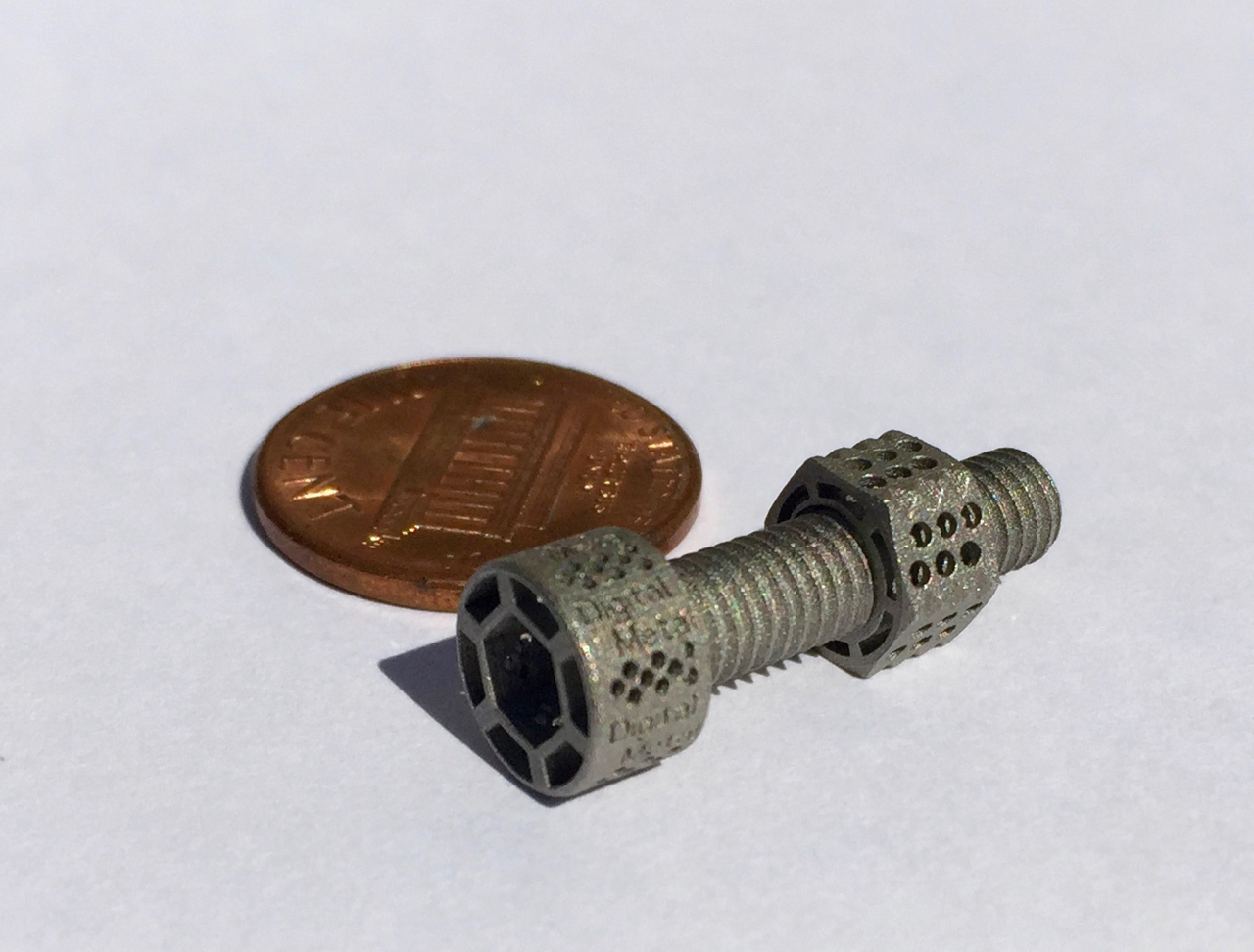

How detailed? Check out the bolt at top and image here. Note the size of this object as compared to the US penny in the background. If you look closely, you can actually read “Digital Metal” on the bolt. Note the very tiny umlauts in the company name. Incredible.

These metal 3D prints are vastly more detailed than you’d find in other metal 3D printing processes, whose resolution ultimately depends on the size of the laser beam, for example.

But what is “Digital Metal”? It’s a surprisingly simple process that should be much less expensive than other processes.

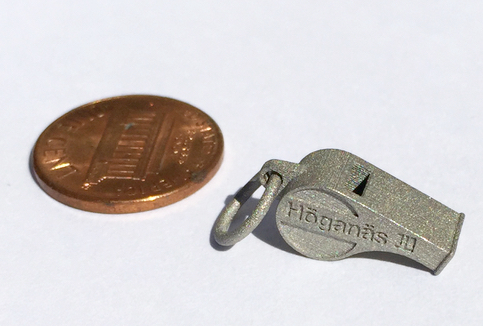

Digital Metal is a cold, powder-based process. A binder is injected via inkjet-style print heads onto a powder bed repeatedly to build up an object. This part is quite similar to powder-based plastic processes, where, for example, you can print full-color objects. But here we are binding metal particles together – and no support structures are required.

Once the print is complete, the residual, unbound powder is blown away safely for reuse in the next print. Then the bound print is carefully removed and a small heat treatment gets rid of the majority of the binder.

The print is then sintered in a separate furnace on a ceramic plate. During the sintering, the temperature is set to just below melting point to fuse the metal particles together.

That’s it. The print is complete at that point. Here’s a graphic of the process.

And what a print! They say they can achieve 0.035mm resolution and the printed parts have 97% density. They say the prints have the same properties as normal injection molding.

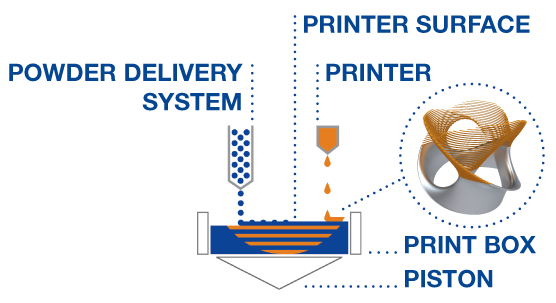

Here’s another very tiny example: a chess piece that is only millimeters tall. Those are fingers, yes.

Höganäs says the DM P1000 printer is priced at a whopping €600,000 (USD$664,000), but that is in line with other metal 3D printing options. But few if any can offer this level of detail.

Two models are presented, the DM P1000, with a 500cc build volume, and the larger DM P2000, with a 1500cc volume (that’s around 110mm on a side for reference). These are small volume printers, to be sure, but such accuracy is usually required only for small items.

I’ll have more thoughts on this amazing technology in a future post.

Via Höganäs