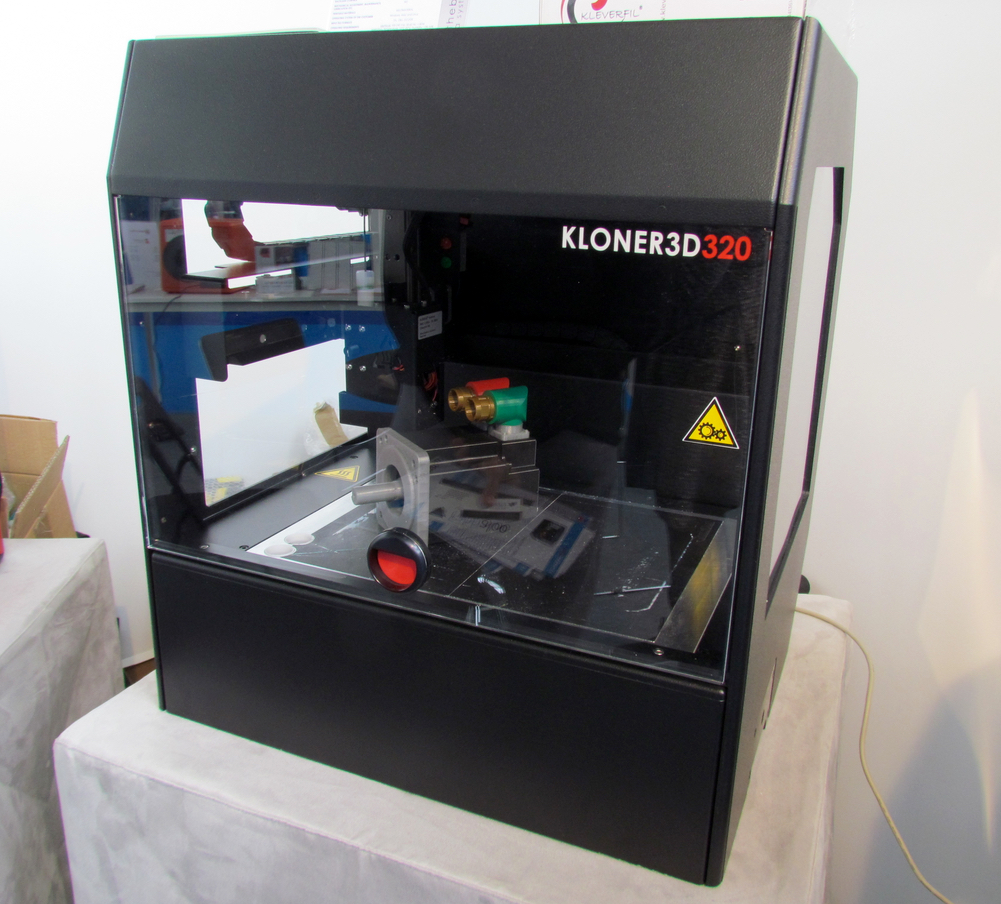

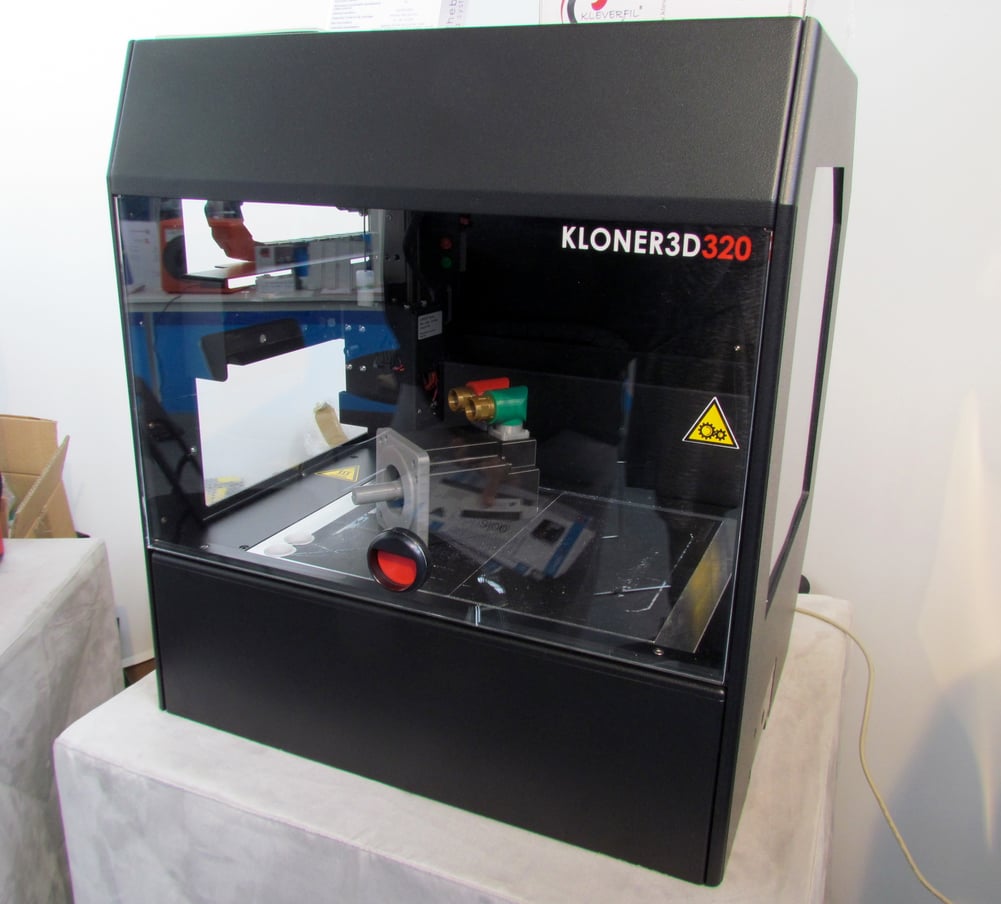

Kloner3D is a Florence, Italy-based 3D printer manufacturer producing now eight machines, including the amazing 240Twin machine.

The company has been around for about three years, coming from a history of producing medical machines. Two years ago they introduced their first 3D printer, but now have grown their product shelf to eight different machines, each addressing different needs.

They have three “lines” of machines: Desktop, Office and Production. We were told the mechanics are similar among the machines, but that the Production machines include certified components and are designed for 24 x 7 use. Hence, “Production”.

The most interesting machine in Kloner3D’s line, in my opinion, is the amazing 240Twin, apparently introduced over a year ago.

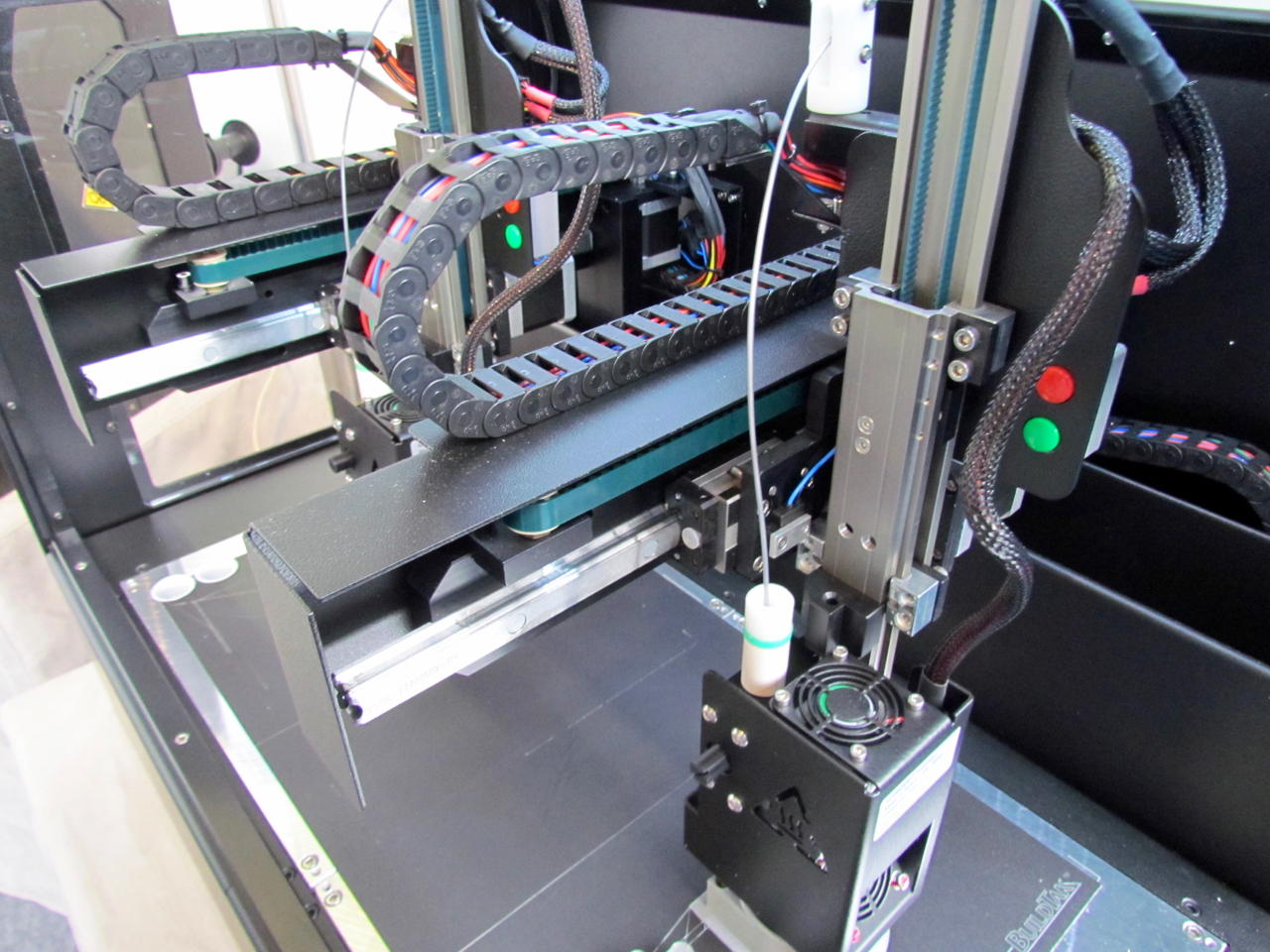

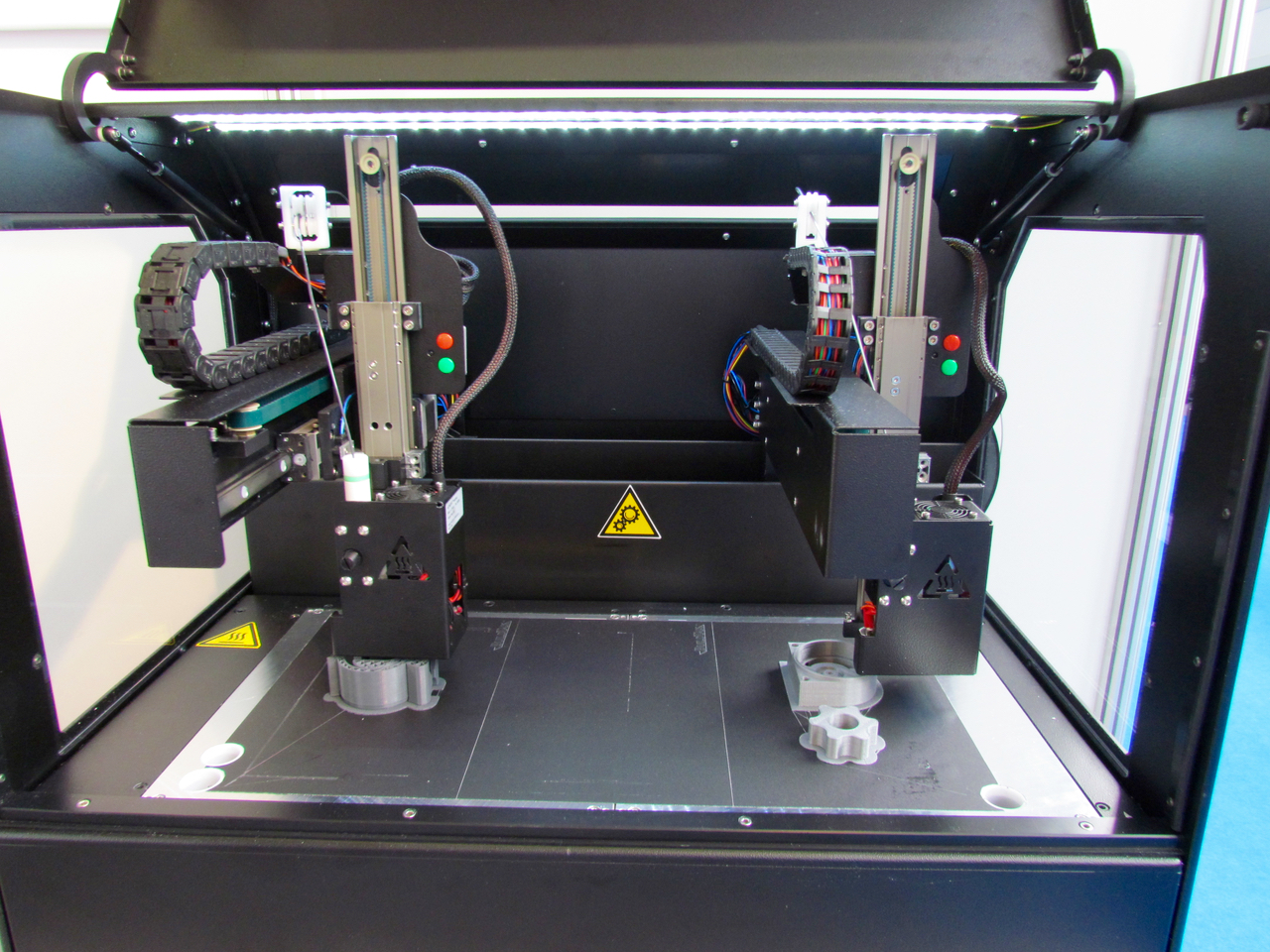

The “Twin” aspect is quite evident when you open up the machine and note that it has two extruder mechanisms. This is not uncommon, but these are separated by quite a distance whereas other dual extrusion machines have them very close to each other.

There’s a good reason for this: they operated independently!

Each print head can move around and print different objects – possibly with different materials – at the same time! In this image you can see the machine printing two different objects.

The 240Twin includes a build volume of up to 360 x 240 x 140mm, but that makes little sense when you are printing two objects. Let’s just say it’s sufficient to print two commonly sized objects at once. They explain it best with this chart:

The minimum layer size is only 0.035mm, so the prints can be quite smooth. It includes an enclosed chamber for increased print reliability and also requires “no mechanical calibration”. Apparently the machine’s design includes a fixed plate that requires no leveling procedure. If you’re using a non-zero thickness adhesion solution, like BuildTak, you do have to adjust the Z-gap, however.

The machine also has an auto-locking door during printing, making the machine a bit more safe for use in schools. In fact, the company says they have sold several to educational institutions. No finger problems!

Sales of the 240Twin are handled by resellers, of which there are several in the European region. However, there are no resellers in the West. Perhaps this is an opportunity for a 3D print entrepreneur?

Via Kloner3D