There’s much competition in the world of 3D print materials, given the vast number of devices loose in the world. Innovation is key and two companies announced new products along that line.

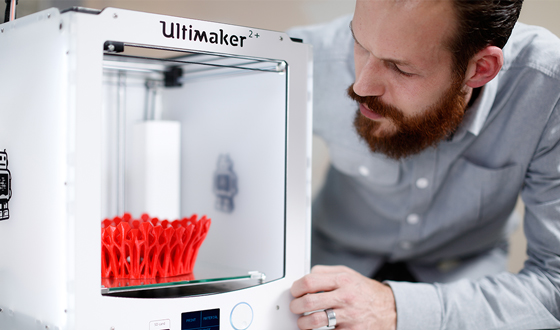

One of them is Ultimaker, one of the original desktop 3D printer companies. Recently Ultimaker has been slowly sliding their focus towards professional users over hobbyists, and their most recent materials announcement seems to follow that pattern.

They announced no less than four new materials, including:

- A chemical-resistant, higher-temperature-resistant robust co-polyester called CPE+

- A polycarbonate filament suitable for low-run manufacturing

- A strong nylon material ideal for many functional applications

- A flexible TPU 95A material that also is chemical resistant

Sounds great, but isn’t this a far cry from the days of “New: Nuclear Green Filament!!!!” These are all highly functional materials suitable for a variety of prototyping and production needs.

Their presence in Ultimaker’s product shelf makes their product appear more professional when inspected by prospective Ultimaker buyers, and it actually is quite suitable for such use.

The other company is AIO Robotics, who specialize in a highly-functional desktop unit engineered for use in educational settings. Their embedded educational projects concept is yet unmatched by other 3D printer manufacturers.

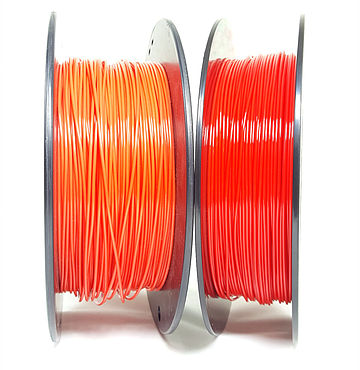

Now they’ve announced a series of 500g filament offerings for their machine – and others, I suppose, as many machines can use each other’s filament.

But there are so many filament options available, one must attempt to differentiate from the competition, and it appears that AIO Robotics is doing so in a slightly different manner than others.

Their new line has a number of interesting attributes that enhance the non-filament portions of the product:

The spool is only 500g, enabling them to offer a thinner spool, which they say “significantly reduces” the chance of tangles. That’s a good idea!

The spool itself is said to be lighter than typical spools, meaning the 3D printer has to exert less force to pull the filament, particularly when starting.

The new 500g spools are stored in plastic bags with anti-moisture bag, like most filament. However, this bag is resealable, which many filament vendors do not provide. Unless you’re printing the ENTIRE spool in one go, you probably need to reseal it in a secure bag.

AIO Robotics also describes a “universal spool design”, said to be “Compatible with all 1.75 mm PLA 3D Printers”. I’m not sure this is a true statement, as there are some pretty screwy 3D printers out there. Nevertheless, it’s a very good idea to at least attempt to be compatible with as many devices as possible.

Innovation continues in the 3D printer filament market. Expect more.

Via Ultimaker and AIO Robotics