Netherlands-based Openplus has launched a very powerful 3D print-driven construction system for furniture.

Their concept is simple, but their execution is even better.

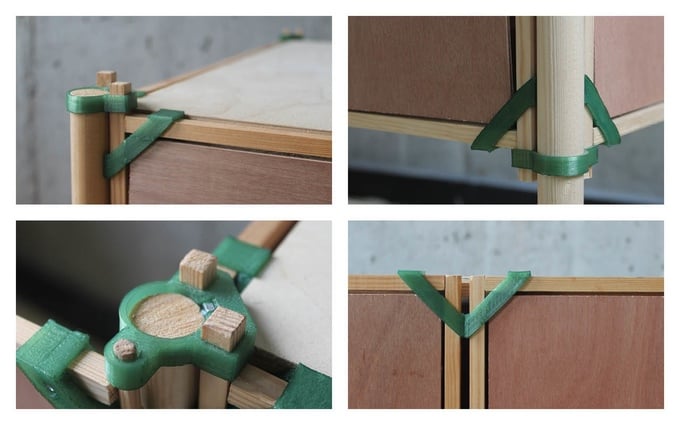

The idea is to enable rapid construction of arbitrary furniture products through the use of a set of ingenious connectors. The connectors will hold standard building materials, such as posts, sheets and the like in position to comprise a furniture item.

We’ve seen this before, such as in this 3D printed system that can be used to build geodesic domes.

However, all of the “connector” style system I’ve seen previously had a flaw: they were static. You could print a pile of connectors and then get to work putting something together. But the new Standard Products approach from Openplus is different, and it starts with software.

As opposed to other systems, Standard Products is a way to design your furniture item and then print the right number and kind of connector components. I’ll stop writing and just let you watch this animation to see how it works:

Your simple design decisions automatically adapt the connector system to perfectly match your intended object.

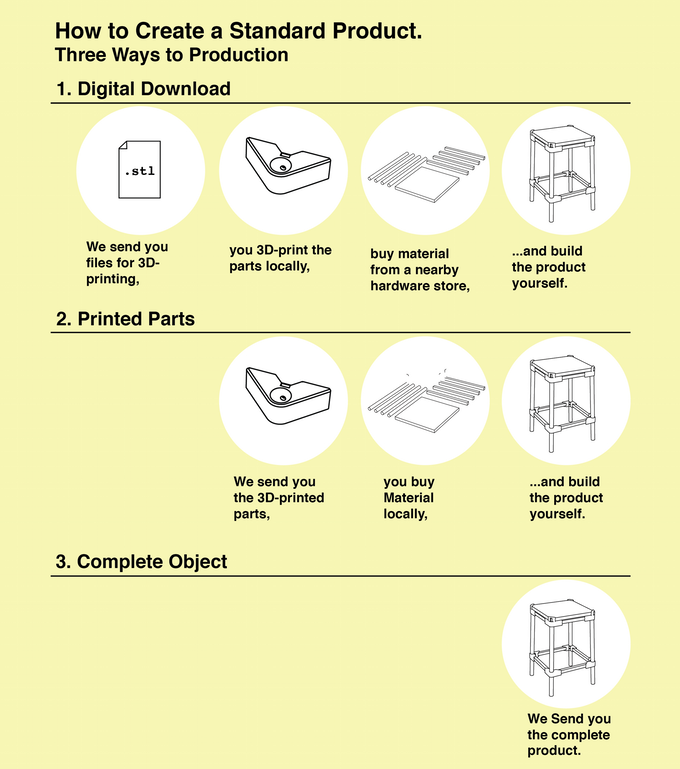

Their workflow is straightforward: perform the design using their service, then they send you a STL file containing the correct connectors for your project. You simply 3D print them yourself (or use a service to do so). You’ll purchase the required materials at your local hardware source and assemble it all together. Simple, isn’t it?

The guys at Openplus also explain that across the world, standard building materials may have somewhat different dimensions. They’ve accounted for this in their system so that it prepares connectors that fit YOUR particular measurements. Thus, you can be sure this will work for your project.

They’ve launched the service via Kickstarter with a stool and cupboard design, but they hope to add many more types of models to their collection. Eventually, one could see an “IKEA-like” service that provides a wide variety of 3D printable, locally made products for the home. This is a very powerful concept.

This might not be the “killer app” for personal 3D printers, but it’s getting there.

Via Openplus and Kickstarter