Finally, someone is doing something about a problem faced by virtually all polymer-based 3D printing: predictability.

Anyone using a thermoplastic-based 3D printer will know that the material is utterly critical to achieving a successful 3D print. 3D printer manufacturers sometimes recommend – or even insist – you use only their plastic filament, not only for profit reasons, but also more importantly because they “know” what it is, chemically. They can predict its behavior in the printer and thus make some assurances about the quality of the print operation and the print itself.

However, in a world of open materials, there are some challenges. Actually, many challenges, but one nefarious issue is that we simply don’t know the nature of one polymer to the next from vendors. While you may operate a 3D printer capable of using “open materials”, you are often on your own to figure out the optimal 3D printing parameters for your particular machine.

And that’s usually just to get the material to print properly, let alone describe the engineering behavior of the printed object afterwards.

A good part of this problem is caused by the lack of standards and specifications in the industry. It’s made worse by many plastics manufacturers and filament sellers rapidly developing their own polymer concoctions, each with some interesting advantages – but how do these new plastics fit into a scheme for predicting print and object behavior?

This year there was some work attempted in this area by the Material Measurement Laboratory of the US National Institute of Standards and Technology. This organization hosted a workshop on the “Measurement Science for Polymer-Based Additive Manufacturing” to begin work on this challenge. They explain:

While the use of AM has been growing, numerous challenges impede its more widespread adoption and commercialization. In many cases, new measurement methods, standards, data, and models are needed to overcome these challenges. These challenges, and the tools that will enable industry to overcome them, were explored in the Roadmap Workshop on Measurement Science for Polymer-Based Additive Manufacturing.

With over 100 expert participants, they explored the following:

- Measurement science barriers, challenges, and gaps that prevent the broad use of polymer-based AM

- Research and development needed to address the priority measurement and standards challenges

- Future measurement- and standards-related targets and goals for AM

- Pathways and approaches to address identified barriers and gaps

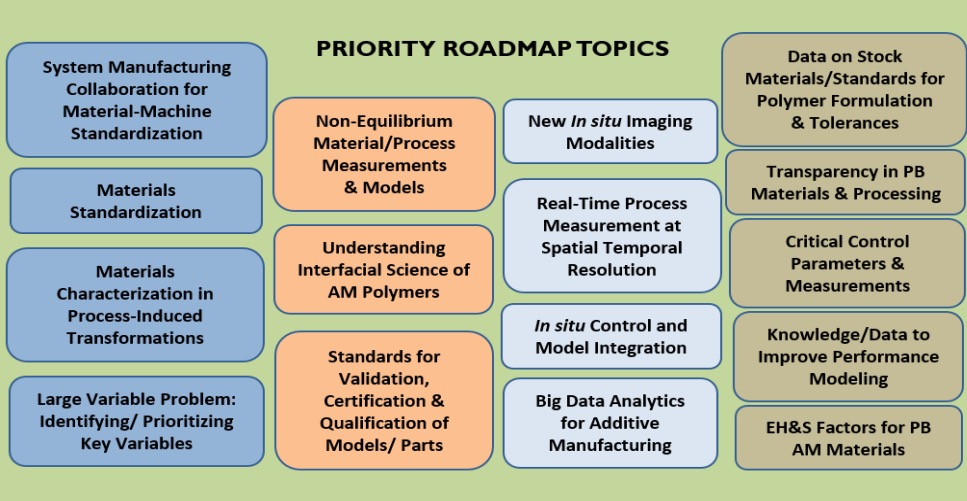

The group found numerous challenges:

- Proprietary equipment, materials, and controls

- Standard for PB AM feedstocks and finished parts

- Limited data / methods to define material process history

- Comparing results and variables across printer platforms

- Non-equilibrium materials and process measurements / models

- Interfacial science for layers, phases and multi-materials

- Accepted guidelines for model development / validation

- In situ imaging modalities for AM printers

- Measuring thermal and chemical distribution of deposited layers

- Comprehensive models to interpret in situ data

- Fast, accurate big data analytical methods for in situ measurements

- Standards for feedstock material tolerances

- Transparency in PG AM and related sciences

- Parameters and variables impacting properties of parts

- Modeling PB AM processes for performance

- Unknowns in health & safety factors

- And a number of non-technical challenges as well

The group’s deliberations led to the development of a comprehensive 49 page roadmap to solve at least some of these challenges.

At this point, however, it’s just a roadmap and it remains to be seen how much of this will be executed, and by whom.

I do hope such standards to emerge, as they could revolutionize how 3D printing is done. Imagine a world where you can pick up virtually any spool of plastic filament and know instantly not only how to successfully print it on your device, but also the complete engineering characteristics of objects printed with it.

We can only hope.

Via NIST (PDF)