MiniFactory’s latest 3D printer is quite different than when we first saw them some three years ago.

The Finnish company started out as many 3D printer manufacturers did in those days: build a basic, but reliable desktop 3D printer. We had not seen their progress for over three years, but recently we got to see one in person and were impressed with the progress made by the small company.

The flagship product is the MiniFactory Innovator, a professional desktop 3D printer, capable of printing many high-temperature materials.

Two models are provided, the L and M, but we’re told the only significant difference between the two is that one uses servo motors instead of stepper motors.

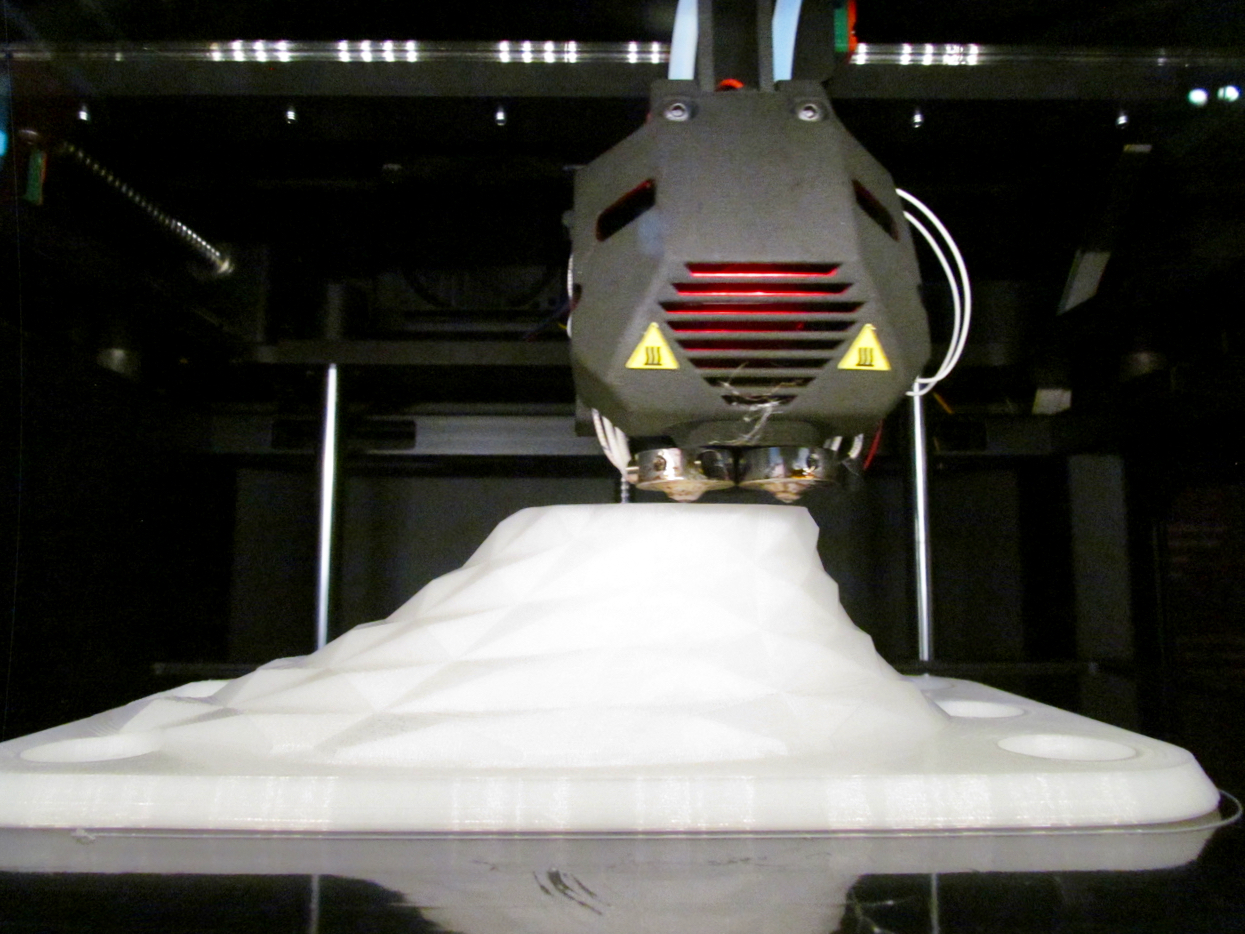

Otherwise the Innovator has a very generous build volume of 330 x 260 x 310mm and can print layers as small as 0.02mm for very fine details. It has dual extruders enabling use of support materials.

The company says it is a very well-calibrated machine and has “no drips from retractions”, unlike some other machines.

The machine is designed to successfully 3D print high temperature materials, including: PLA, ABS, Nylon, PEEK, PVA, carbon fibre (PLA), graphene (PLA), PC and more. It does this by completely enclosing the build chamber and controlling the heat from the build plate though a venting system that maintains a set temperature. For example, when printing PLA, it is set to 30C, while ABS has it set to 55C.

The hot end can go up to 390C, enabling printing of many high temperature materials. We’re told it could theoretically go up as high as 440C, but that might be something to emerge on a future model.

This high heat situation causes changes not only to the hot end and ventilation, but also to the mechanical components. If using the standard 3D printer design approach, they might have used plastic belts to drive the motion system. However, in a high heat situation, plastic belts are not optimal. Thus the Innovator includes ball screws to generate motion instead of belts, making the system much more reliable.

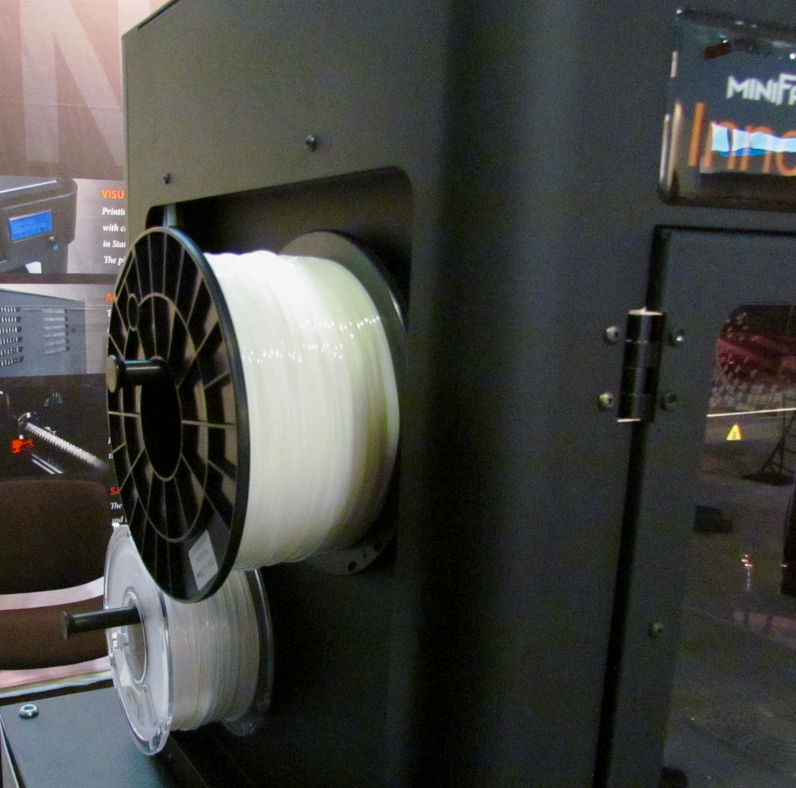

This is an open materials machine, meaning you can put any 1.75mm filament through it. But when 3D printing exotic materials, you may sometimes generate noxious emissions. Those are handled by the Innovator’s on board activated carbon HEPA filtration system, making this unit acceptable for office use.

MiniFactory does not provide custom software to drive this machine, but instead provides a copy of Simplify3D, an excellent third party 3D printer slicing program.

The machines are available now, priced at €6,300 (USD$6,500) and €7,600 (USD$7,900). While they’re very popular in Finland, being sold to both business and education markets, I suspect they’re interested in finding dealers and resellers to broaden their reach.

Via MiniFactory