One of the first things you may encounter when beginning 3D printing is rafts. But are they a good thing or bad?

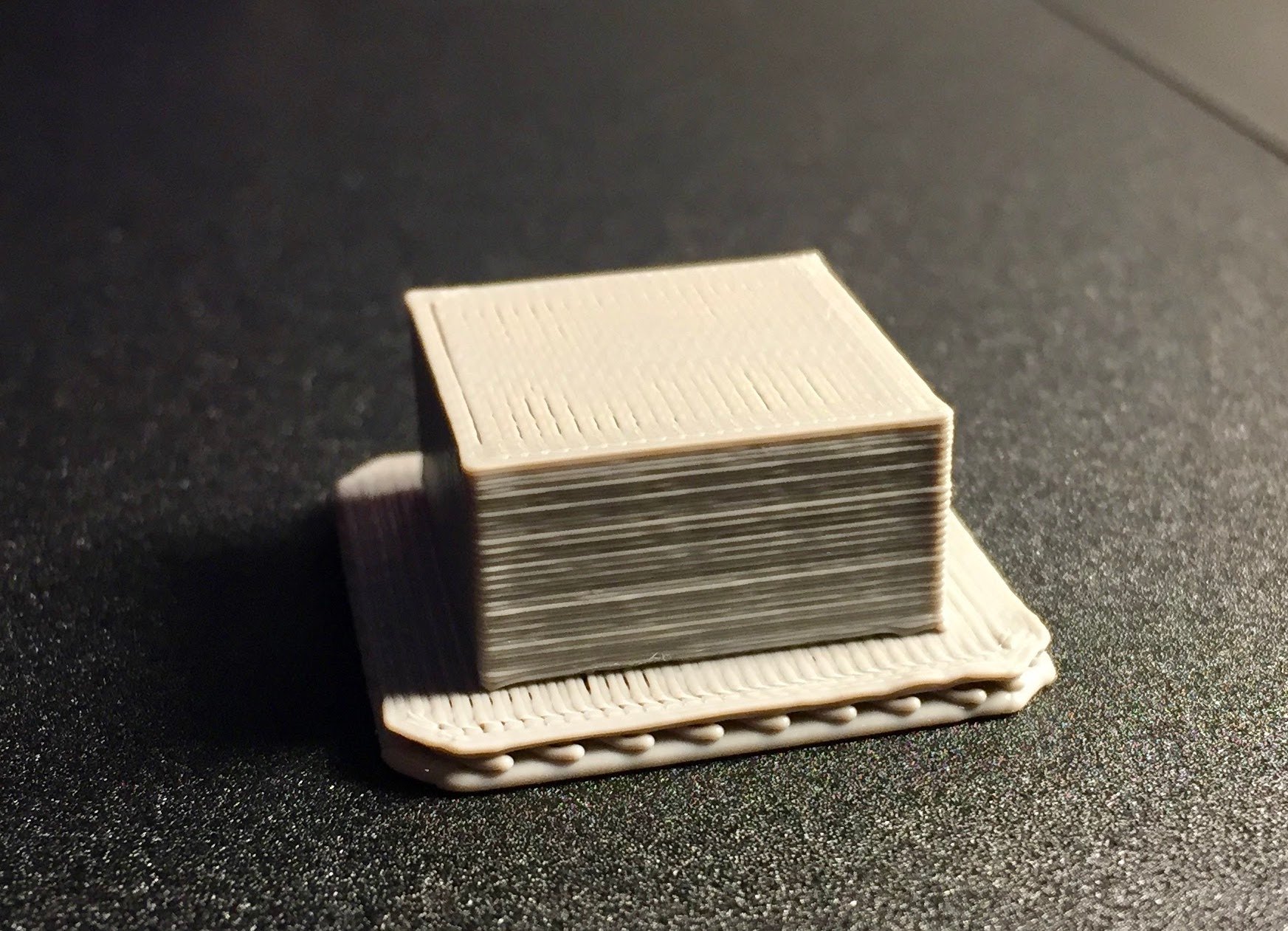

A “raft” is a throwaway portion of a print that essentially lays down a flat area on the print surface on top of which is printed the actual desired 3D model.

Rafts can be of many forms, but most often they are comprised of several layers of differing composition.

Sometimes they are automatically generated by slicing programs that prepare 3D models for printing, and other times they are optional. But regardless, there are some pros and cons of using rafts.

The Good

A raft produces a known good temporary print surface. One of the persistent issues in filament-based 3D printing is the quality of the print surface. It may be tilted, bent or at an inappropriate distance from the nozzle tip.

By using a raft, such issues are all but eliminated in situations where the machine is not completely out of calibration. The first layer of the raft takes the brunt of the mis-calibrations, leaving subsequent layers much more consistent conditions. Why? Because the machine is more or less guaranteed to lift consistently for the second layer. If the build plate is tilted, the second layer will be far less so.

It’s best to have a bulky raft, designed for adherence, take the first layers instead of hoping your spindly object sticks for the entire print.

Depending on the structure of the raft, it’s also possible to somewhat reduce the effects of warping. A good raft will have internal disconnects to avoid length-amplifying strands of plastic that can shrink, for example.

The raft can make printing more reliable than not, especially if the object has an unusual shape.

The Bad

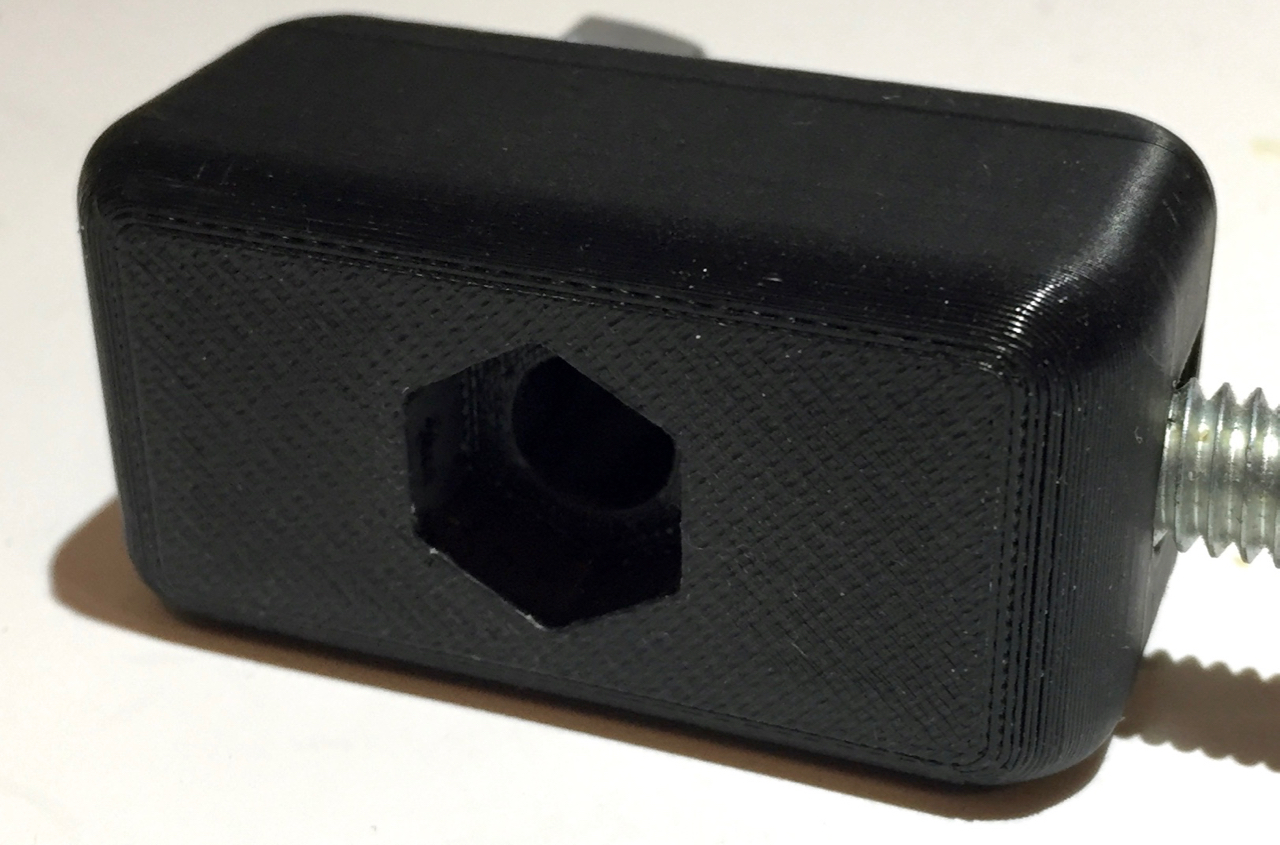

When using a raft, the bottom layer of your object, which typically holds the major flat portion of the shape, takes on a relatively rough surface texture. That’s because the raft isn’t completely flat. If printing raftless on a perfectly flat surface, such as glass, you’ll get a mirror-finish on the bottom layer, which could be desirable. Not possible with a raft.

The Ugly

The worst aspect of raft-printing is the removal stage. You obviously don’t want the raft to be permanently attached to your print, so you must peel it off. Unfortunately, “peeling” is most often not the case and some rafts simply don’t want to release. At worst, this excess plastic can pollute the print sufficiently to be unusable. You may even break the print itself when wrestling with an uncooperative raft. I’ve even cut myself badly when using hand tools to remove rafts.

Some slicing systems permit adjustment of the layer size between the top of the raft and the bottom of the object. By increasing the factor, you can sometimes make rafts easier to remove.

The best raft-generating software is highly tuned to provide both a great ability to stick to the print surface during printing, but also provide a very easy way to remove the raft after printing completes.

In some cases, machine configurations insist on using a raft, but other machines consider it an optional feature. What should you do? If you have a choice, I recommend examining the situation carefully and making a decision. Ask yourself the following questions:

- Do I need a high-quality bottom layer?

- How big is the object?

- Does the bottom layer of the object have an irregular surface?

- Does the object not have a flat bottom area sufficient to support adherence during the entire print?

Based on your answers, you can make a decision on whether to use a raft.