With all the buzz about new startups featuring fast 3D printing systems, it’s easy to forget that EnvisionTEC has a similar system as well.

The buzz, perfected by Carbon, is about something called “continuous 3D printing”, where instead of the usual “print a layer, move up, print another layer” process, there is a “continuous” printing process where there layers matter far less. In such systems the Z-axis, which normally jumps one layer at a time, instead moves continuously at a slow pace.

Resin 3D printers originally had a severe constraint: errant adhesion of freshly fused layers to the bottom of the resin tank required a slow movement to “peel” the material from the bottom of the tank and present the fresh layer for addition of a new one.

This peel movement dramatically slows the printing process as it is required on each and every layer. If you have hundreds of layers on a finely-resolved object, that can add up to significant print time.

Carbon got around the problem by inventing a special tank that uses oxygen to prevent adhesion. Other companies have developed unique chemistries or special tank surfaces to achieve much the same thing.

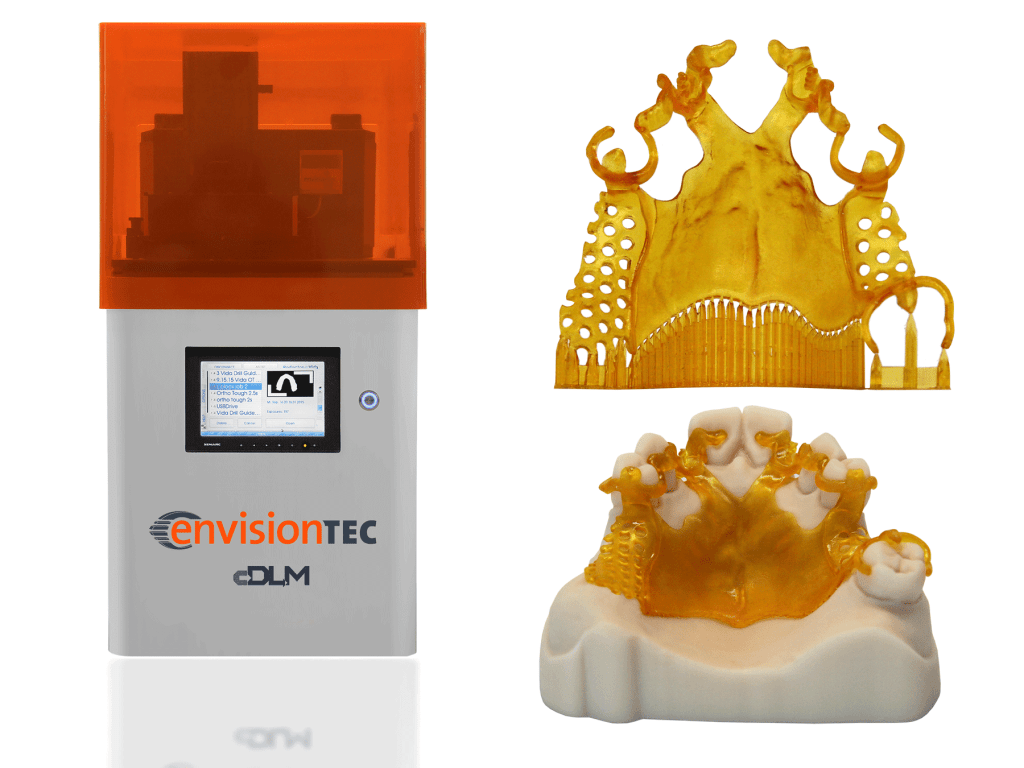

But EnvisionTEC also has such a system, which they call “Continuous Digital Light Manufacturing”, or cDLM. It’s available on two of their machines presently.

The latest addition to their cDLM family is the Perfactory Vida cDLM, which they explain as follows:

The Vida cDLM uses EnvisionTEC’s patented Continuous Digital Light Manufacturing (cDLM) technology, allowing dental professionals to produce partial dentures and waxups in a fraction of the time as previous methods. The surface quality of the printed models allows for production with no signs of stairstepping, unlike the visibility when using competing technologies.

And that is one of the key advantages of continuous 3D printing: no layers!

The Vida cDLM is designed for dental production, and thus has a relatively small build volume of 96 x 54 x 100mm, but it can print pixels as small as 0.05mm – that’s on the X-Y axes. On the Z-axis, it’s continuous, remember? Actually they say that the Z resolution is effectively in the range of 0.025-0.150mm.

It’s good to see EnvisionTEC gaining such a feature, as there is huge competition in the high-resolution resin 3D printer space. I am now beginning to believe that you might almost say there are two categories of resin 3D printers these days: “normal” and “continuous”.

The Vida cDLM will be shown to the public at LMTmag’s LMT LAB day that takes place in Chicago this week. This is another example of a 3D printer company reaching our beyond the 3D printing space to interact directly with those who might apply their technology to a particular commercial domain.

Via EnvisionTEC